Catalyst for preparing methylacrolein in fixed bed, preparation method and application

A technology of methacrolein and methylenebisacrylamide, which is applied in catalyst activation/preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as poor repeatability, poor sintering activity, and poor uniformity. , to achieve the effect of small particle size, reduced powder agglomeration, and easy control of uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

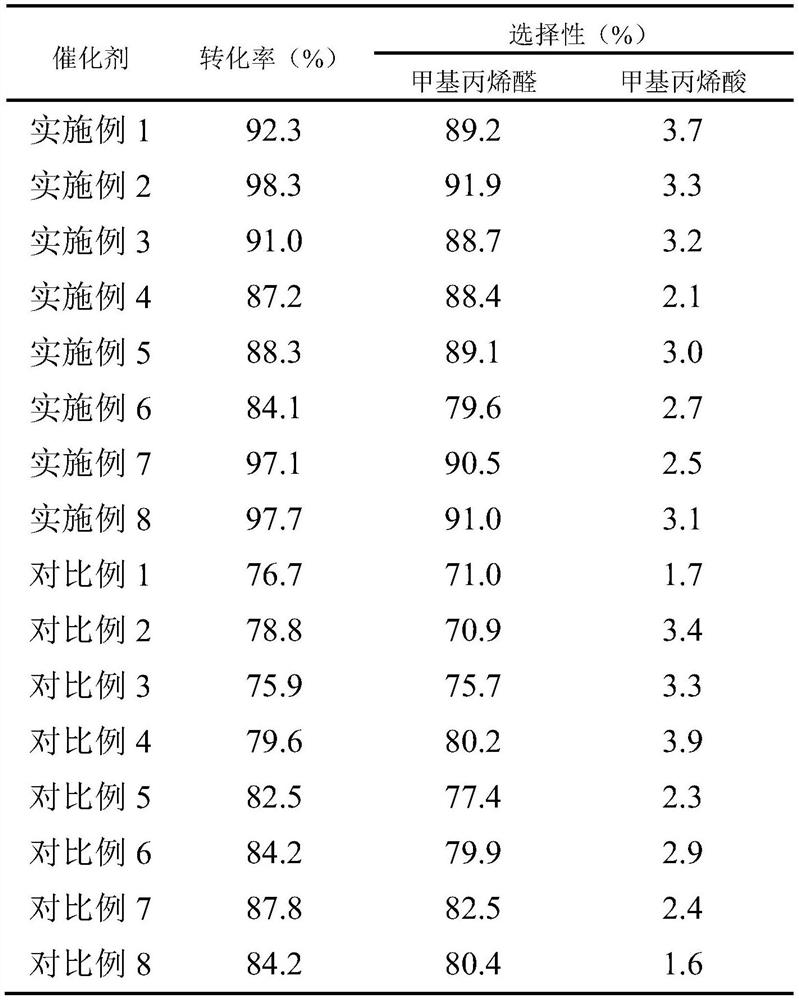

Embodiment 1

[0078] Dissolve 12.6g bismuth nitrate pentahydrate, 16.9g ferric nitrate nonahydrate, 12.2g cobalt nitrate hexahydrate, 12.4g copper nitrate hexahydrate, 5.38g magnesium nitrate hexahydrate, 2.72g cesium nitrate in 100mL 5% nitric acid solution at 50°C After the solution is clear and transparent, add 25g of tartaric acid. After the tartaric acid is completely dissolved, add 10g of glucose. After the addition, the concentration of sugar in the system is 0.1g / mL. 350mL solution. Each of the above steps is accompanied by stirring to fully dissolve the additives. After the solution is evenly mixed, add 150mL of a solution containing 50g of ammonium heptamolybdate tetrahydrate after clarification. Finally, heat the resulting mixed solution to 80°C to make After a polymerization reaction occurs, the solution is slowly transformed into a gel. The obtained gel is placed in a constant temperature drying oven to dry to form a xerogel. The xerogel is ground into a fine powder and calcined...

Embodiment 2

[0081] Dissolve 12.6g of bismuth nitrate, 16.9g of iron nitrate, 12.2g of cobalt nitrate, 6.2g of copper nitrate, 5.38g of magnesium nitrate, and 2.72g of cesium nitrate in 100mL of 5% nitric acid solution at 50°C. After the solution is clear and transparent, add 25g of tartaric acid. After the tartaric acid is completely dissolved, add 10g of glucose, the concentration of sugar in the system after adding is 0.1g / mL, then add 350mL solution containing 278g of acrylamide and 62g of methylenebisacrylamide. Each of the above steps is accompanied by stirring, so that The additives are fully dissolved. After the solution is mixed evenly, add 150mL of a solution containing 50g of ammonium heptamolybdate after clarification. Finally, heat the resulting mixed solution to 80°C to make it polymerize. Wait until the solution slowly turns into a gel. The obtained gel was dried in a constant temperature drying oven to form a xerogel. The xerogel was ground into a fine powder and calcined a...

Embodiment 3

[0084] Dissolve 12.6g of bismuth nitrate, 16.9g of iron nitrate, 12.2g of cobalt nitrate, 12.4g of copper nitrate, 10.75g of magnesium nitrate, and 2.72g of cesium nitrate in 100mL of 5% nitric acid solution at 50°C. After the solution is clear and transparent, add 25g tartaric acid. After the tartaric acid is completely dissolved, add 10g of glucose, the concentration of sugar in the system after adding is 0.1g / mL, then add 350mL solution containing 278g of acrylamide and 124g of methylenebisacrylamide. Each of the above steps is accompanied by stirring so that The additives are fully dissolved. After the solution is mixed evenly, add 150mL of a solution containing 50g of ammonium heptamolybdate after clarification. Finally, heat the resulting mixed solution to 80°C to make it polymerize. Wait until the solution slowly turns into a gel. The obtained gel was dried in a constant temperature drying oven to form a xerogel. The xerogel was ground into a fine powder and calcined at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com