A preparation method of low-current-noise high-resistance dispersive chip resistor paste

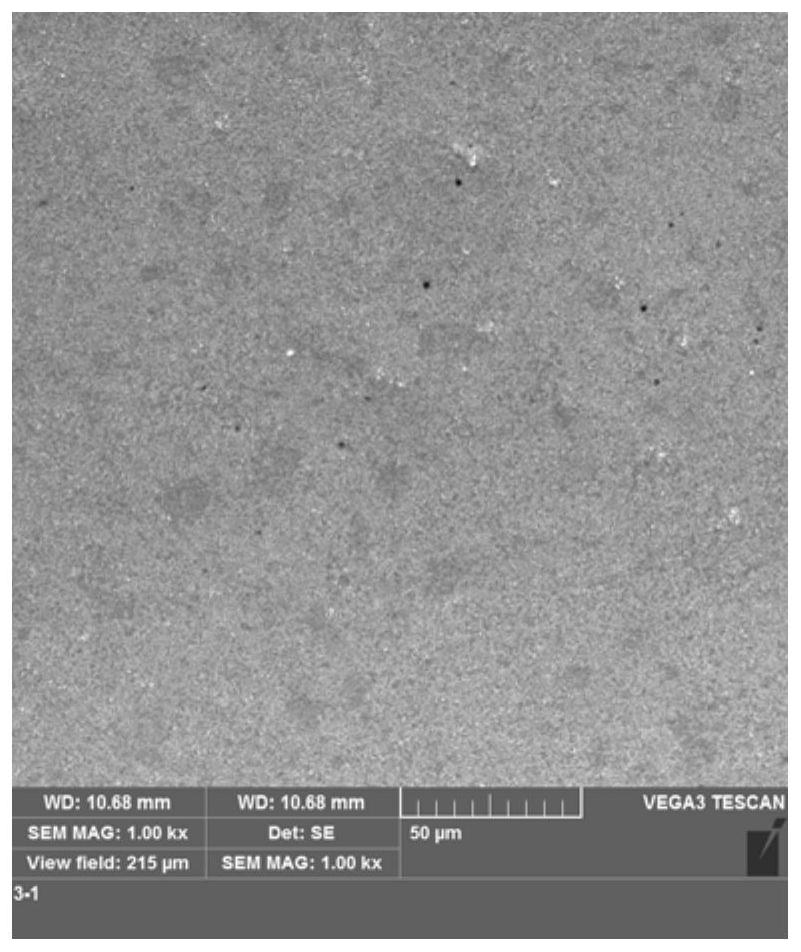

A technology of resistance paste and high resistance value, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, coating resistance materials, cable/conductor manufacturing, etc., and can solve problems such as easy powder agglomeration and sintered film surface cracking , to achieve good resistance dispersion, compact surface, and reduce the effect of mixing powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

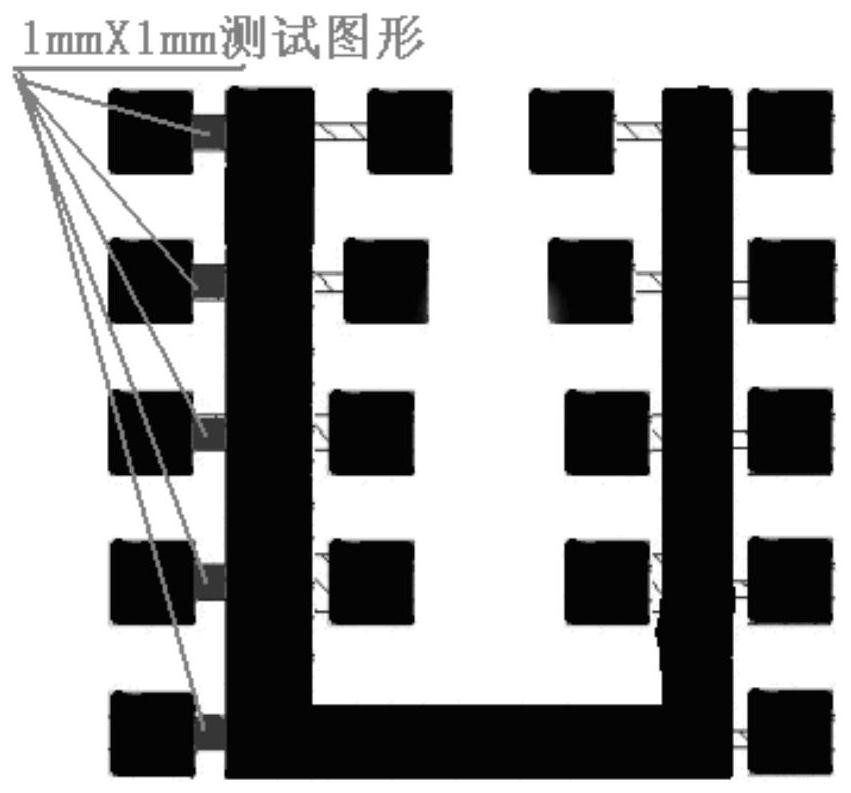

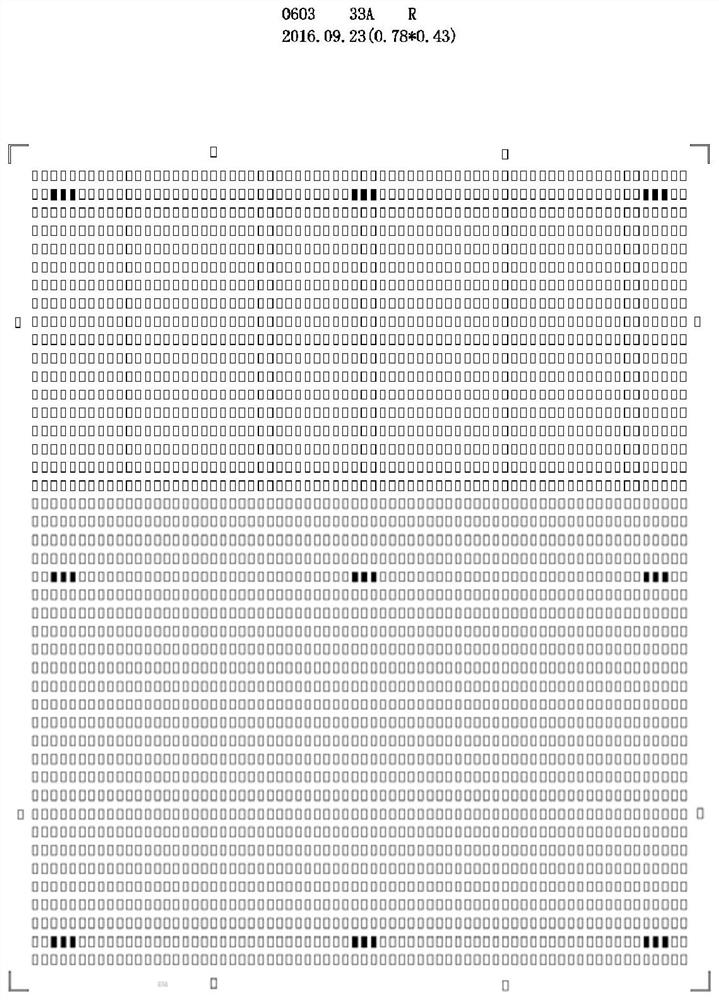

[0037]1. Take 50g of ruthenium oxide, 50g of lead ruthenate, 50g of glass powder, 50g of zirconium silicate, and 50g of manganese oxide, and add them to 100g of 2,5-dimethyl-3-hexyne-2 with a mass concentration of 0.2%, In the ethanol solution of 5-diol, disperse for 6 minutes at a speed of 20,000 rpm in a homogenizer, dry in a blast drying oven at 40-50°C, and store at a low temperature of 4°C.

[0038] 2. Take 8g of ruthenium oxide, 8g of lead ruthenate, 50g of glass powder, 4g of zirconium silicate, and 0.8g of manganese oxide after pretreatment in step 1, add them to 29.2g of organic carrier, stir evenly with a glass rod and place for 1h to complete infiltration ; Then use a mixer to mix the materials and use a three-roller to roll to obtain a sheet resistance slurry with a fineness of ≦5 μm.

Embodiment 2

[0040] 1. Take 50g of ruthenium oxide, 50g of lead ruthenate, 50g of glass powder, 50g of zirconium silicate, and 50g of manganese oxide, and add them to 100g of 2,5-dimethyl-3-hexyne-2 with a mass concentration of 0.5% respectively, 5-diol in ethanol solution, and disperse for 5 minutes at the speed of homogenizer at 16500 r / min, dry at 40-50°C in a blast drying oven, and store at a low temperature of 4°C.

[0041] 2. Take 8g of ruthenium oxide, 8g of lead ruthenate, 50g of glass powder, 4g of zirconium silicate, and 0.8g of manganese oxide after pretreatment in step 1, add them to 29.2g of organic carrier, stir evenly with a glass rod and place for 1h to complete infiltration ; Then use a mixer to mix the materials and use a three-roller to roll to obtain a sheet resistance slurry with a fineness of ≦5 μm.

Embodiment 3

[0043] 1. Take 50g of ruthenium oxide, 50g of lead ruthenate, 50g of glass powder, 50g of zirconium silicate, and 50g of manganese oxide, and add them to 100g of 2,5-dimethyl-3-hexyne-2 with a mass concentration of 0.8%, In the ethanol solution of 5-diol, disperse for 4 minutes at the speed of 15,000 rpm in a homogenizer, dry at 40-50°C in a blast drying oven, and store at a low temperature of 4°C.

[0044] 2. Take 8g of ruthenium oxide, 8g of lead ruthenate, 50g of glass powder, 4g of zirconium silicate, and 0.8g of manganese oxide after pretreatment in step 1, add them to 29.2g of organic carrier, stir evenly with a glass rod and place for 1h to complete infiltration ; Then use a mixer to mix the materials and use a three-roller to roll to obtain a sheet resistance slurry with a fineness of ≦5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com