Aluminum alloy cutting fluid

A cutting fluid, aluminum alloy technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of spoilage of cutting fluid, tool wear, short service life, etc. The effect of the bubble problem

Inactive Publication Date: 2015-08-05

DONGGUAN PAOO LUBRICANT

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aluminum alloy cutting fluid products of the prior art generally have the basic properties of lubrication, cooling and cleaning, large-scale production of modern industry, high cutting speed and high feed rate in high-speed machining process, aluminum alloy production and processing process, especially In the water-based cutting fluid processing process, the oxidation corrosion problem and tool wear problem of the product are relatively serious, and the processing equipment is also prone to rust, and the foam is serious during the processing process, which affects the lubrication and cooling of the cutting fluid; in addition, the cutting fluid is prone to corruption and qualitative change , shorter service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

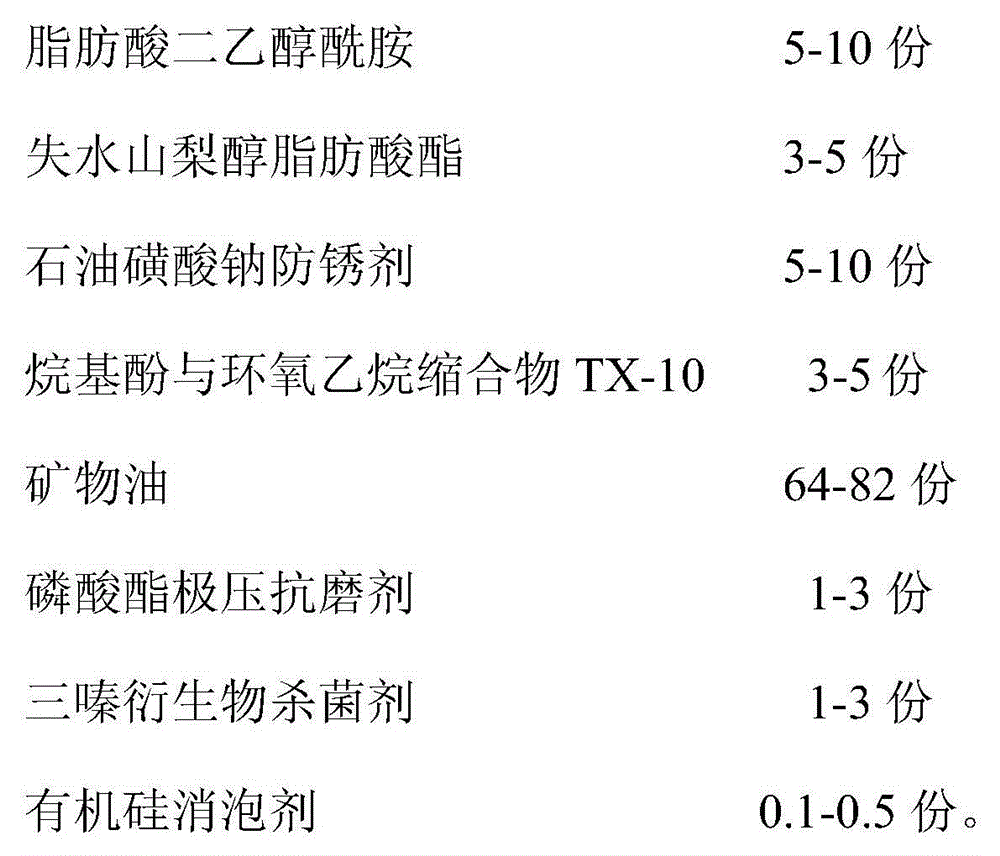

[0012] An aluminum alloy cutting fluid, the cutting fluid contains the following components by weight:

[0013]

Embodiment 2

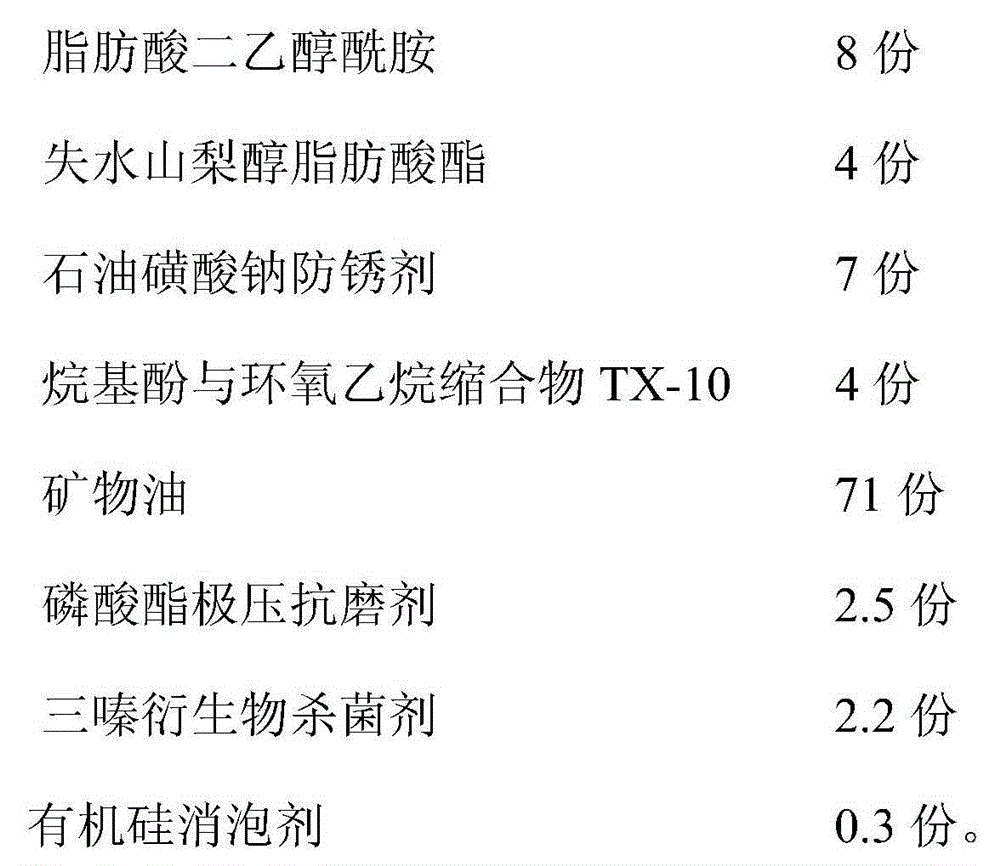

[0015] An aluminum alloy cutting fluid, the cutting fluid contains the following components by weight:

[0016]

[0017]

Embodiment 3

[0019] An aluminum alloy cutting fluid, the cutting fluid contains the following components by weight:

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of industrial grease, in particular to aluminum alloy cutting fluid. The formula of the aluminum alloy cutting fluid achieves a good cooling and lubrication effect on a machined workpiece in the aluminum alloy production and machining process; the organophosphate is adopted as an inhibitor in the formula, and the problem of oxidative corrosion and the problem of tool wear in the machining process of the aluminum alloy by water-base cutting fluid are effectively inhibited by the inhibitor and an anti-wear agent; meanwhile fatty acid diethanol amide and petroleum sodium sulfonate are used as an anti-rust agent so as to effectively protect mechanical equipment; a triazine derivative bactericide is added to effectively prevent the cutting fluid from easy corruption and qualitative change and prolong the service life; besides, the problem of bubbling is avoided by an organic silicon defoamer, so the machined workpiece is fully lubricated and cooled.

Description

technical field [0001] The invention relates to the technical field of industrial grease, in particular to an aluminum alloy cutting fluid. Background technique [0002] Aluminum alloy materials are currently widely used in automotive engines, transmissions, aviation equipment and other mechanical equipment industries. Therefore, the demand for special cutting fluids for aluminum alloy processing is increasing. Aluminum alloy cutting fluids provide high cutting speed and high progress when processing aluminum materials. The excellent lubricity and cooling required by the rate can greatly improve the service life of the tool and the surface finish of the workpiece. Aluminum alloy cutting fluid products of the prior art generally have the basic properties of lubrication, cooling and cleaning, large-scale production of modern industry, high cutting speed and high feed rate in high-speed machining process, aluminum alloy production and processing process, especially In the wate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10M141/10C10M141/08C10M141/06C10M141/12C10N30/06C10N30/12C10N30/16

Inventor 夏元秀

Owner DONGGUAN PAOO LUBRICANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com