A risk-based equipment integrity management system for oil refining enterprises

A management system and integrity technology, applied in the field of petroleum and natural gas engineering, can solve problems such as the lack of a refinery enterprise system method, low level of equipment integrity management, and insufficient equipment management system, so as to achieve world-class information capabilities, The effect of promoting the informationization of equipment risk management and improving the level of equipment management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

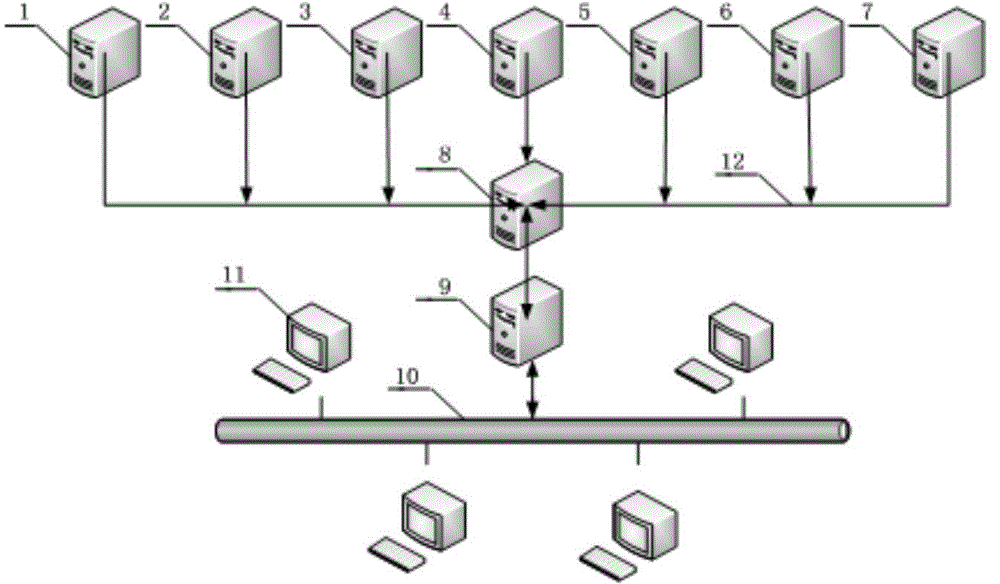

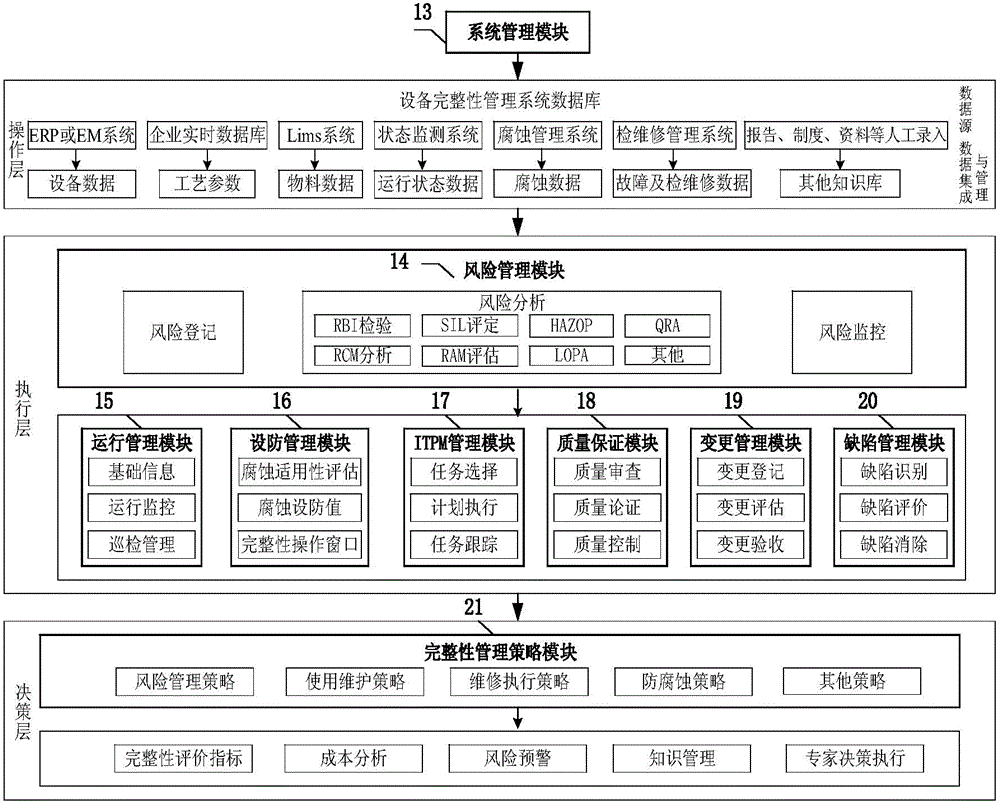

[0021] A risk-based equipment integrity management system for oil refineries, including hardware and technical management software.

[0022]The hardware consists of the PM module (or EM system) data (equipment data) library server of the ERP system, the enterprise real-time data (process parameter) library server, the Lims system data (material data) library server, the corrosion management system data (corrosion monitoring and detection, etc.) data) database server, dynamic equipment condition monitoring system data (operating status data) database server, maintenance management system data (fault and maintenance history data) database server, management system central database server, Web server, local area network, client and Dedicated data lines constitute. Enterprise equipment data, process parameters, material data, dynamic equipment operation status data, corrosion monitoring and detection data, equipment failure and inspection and maintenance history data, etc. can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com