Novel absorber

An adsorber and a new type of technology, applied in the field of new adsorbers, can solve the problems of increasing the contact time between organic waste gas and adsorbent, which has not yet been seen, and achieve the effects of small footprint, improved adsorption uniformity, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific examples of the present invention are given below, but the present invention is not limited by the examples:

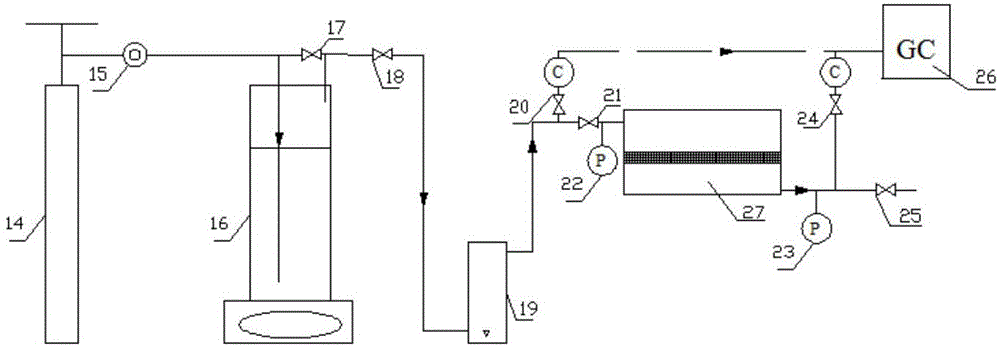

[0022] The organic waste gas is simulated by the mixed gas of n-hexane and nitrogen, and when the intake flow rate is 0.15L / min, the technical scheme of the present invention is used to carry out adsorption, separation and recovery.

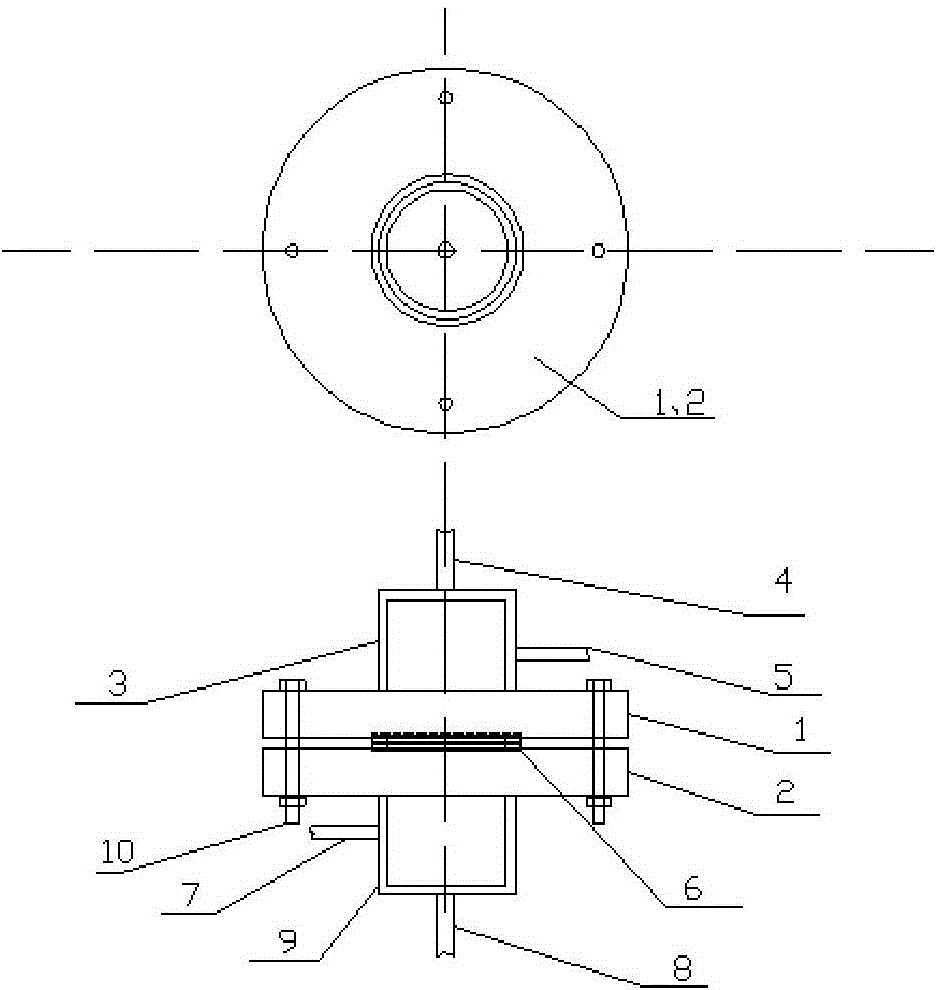

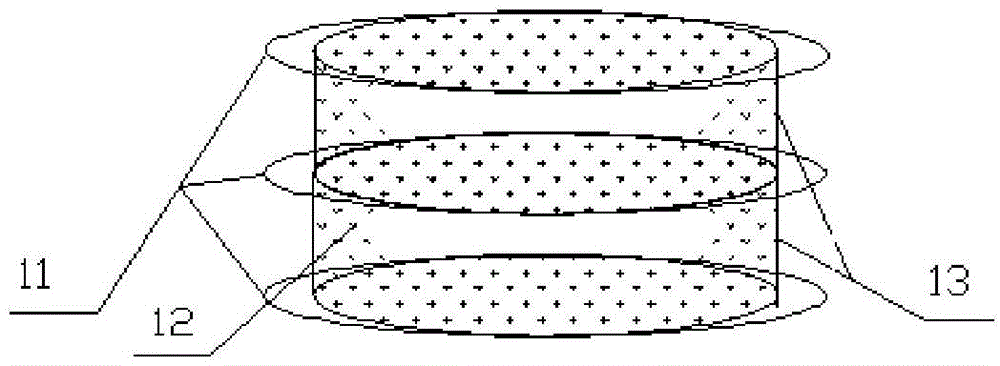

[0023] (1) described a kind of novel adsorber, as figure 1 As shown, it includes an adsorber top cover 3 , an adsorber assembly 6 and an adsorber bottom cover 9 . The components are connected by the upper flange 1, the lower flange 2, and four identical bolts 10; the top cover of the adsorber 3 is provided with an exhaust port 4 and a pressure measurement sampling tube 5; the adsorber assembly 6 is composed of micropores The filter membrane 11 is composed of a rubber flat gasket 13; the bottom cover of the adsorber is provided with an air inlet 8 and a pressure measuring and sampling tube 7.

[0024] Further, in the nov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com