Ship pollution treating system, and drying box, incinerator and exhaust evaporation device arranged on ship pollution treating system

A treatment system and evaporation device technology, applied in water treatment devices, sludge treatment through temperature control, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of difficult crew, small hull treatment site, high operating cost, etc., to achieve The effect of saving electrodes, occupying a small area, and operating costs is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

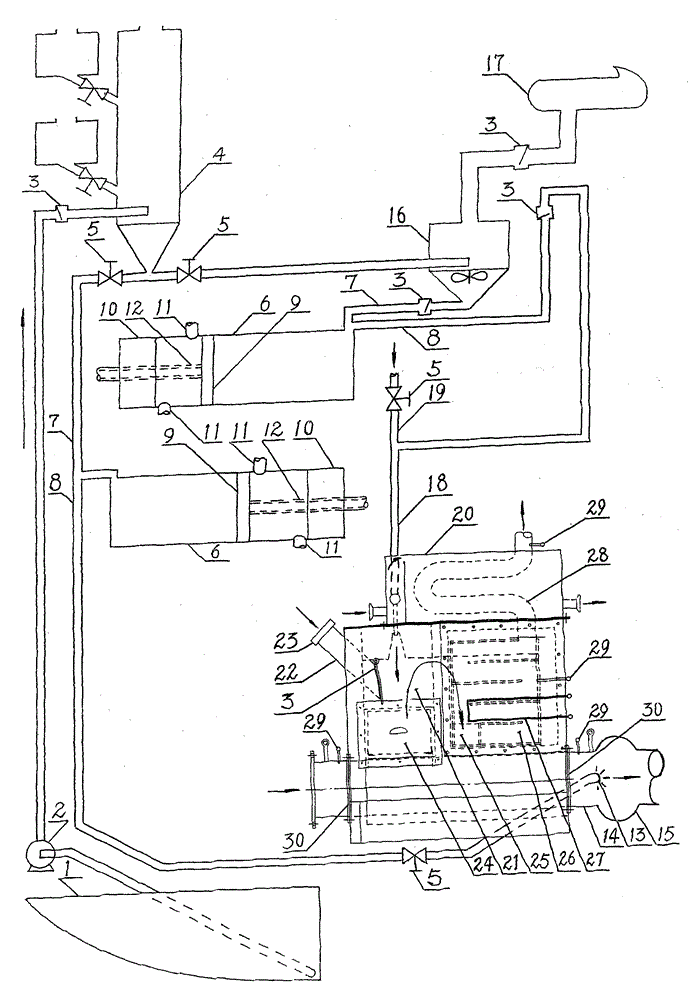

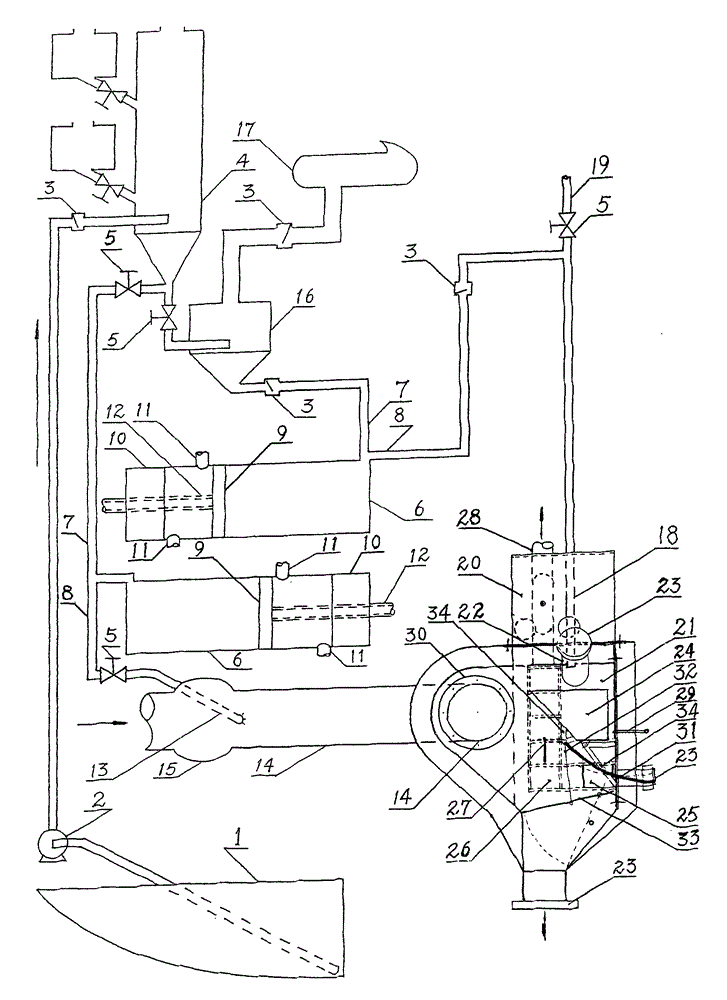

[0029] The sewage pipes for bathing, washing, kitchen and bilge are connected to the sewage tank 1, the water inlet pipe of the water pump 2 extends into the bottom of the sewage tank 1, and the outlet pipe of the water pump 2 is connected to the check valve 3 and then tangentially connected to the mixed sedimentation tank 4, A solenoid valve 5 or a check valve 3 connected to the pipeline under the cone of the mixed sinking tank 4 is connected to the plunger metering pump 6 through the pump inlet pipe 7;

[0030] The plunger metering pump 6 is composed of a pump body, a pump inlet pipe 7, a pump outlet pipe 8, a piston 9, a stepping motor 10 or a feeding motor or an electric variable speed change mechanism, a cleaning pipe 11, and air intake and exhaust holes. The screw rod 10, that is, the piston rod 12 is provided with a waterproof sleeve, the piston rod 12 is connected to the piston 9, and the piston 9 is placed in the pump body, the pump outlet pipe 7 of the plunger meterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com