Device and method for extracting sodium dihydrogen phosphate dihydrate by using crude brine in glyphosate production process through glycine method

A technology of disodium hydrogen phosphate dihydrate and glyphosate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of low mixing ratio of industrial-grade phosphate and active ingredients of disodium hydrogen phosphate dodecahydrate. Low, odor and other problems, to reduce sales pressure, reduce environmental pressure, reduce odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

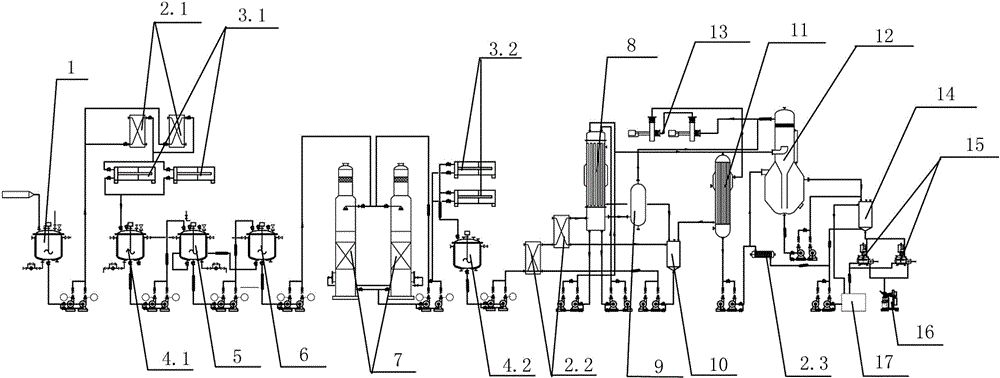

[0026] The disodium hydrogen phosphate dodecahydrate obtained from the extraction process in the salt workshop of our company enters the dissolution tank and is heated to 60°C for dissolution. Activated carbon is treated in the process of fine removal, and finally enters the MVR evaporation and concentration device, and after centrifugation, the finished product of disodium hydrogen phosphate dihydrate is obtained.

[0027] A device for extracting disodium hydrogen phosphate dihydrate from crude brine in the process of producing glyphosate by glycine method. Dissolving tank 1 is connected to heat exchanger one 2.1 through a feed pipe, and heat exchanger one 2.1 is connected to filter one 3.1, wherein The heat exchanger one 2.1 also forms a circulation loop with the dissolving tank 1 through the feed pipe, and the filter one 3.1 is connected with the buffer tank one 4.1, the deamination kettle 5 and the decolorization kettle 6 successively through the feed pipe;

[0028] The de...

Embodiment 2

[0039] In the present invention, the disodium hydrogen phosphate dodecahydrate from the self-made salt workshop will be poured into the dissolving tank for heating and dissolving, and the solution will pass through the heat exchanger and enter the buffer tank, and the solution will enter the deamination kettle, decolorization kettle, and decolorization tower successively, and the solution that comes out will pass through the decolorization tank. The heat exchanger enters the continuous evaporation device, the slurry enters the crystallizer for crystallization, and the crystallized product enters the thickener for continuous crystallization, and the crystal slurry liquid finally enters the centrifugal packaging to obtain the finished product of disodium hydrogen phosphate dihydrate.

[0040] A method for extracting disodium hydrogen phosphate dihydrate from crude brine in the process of producing glyphosate by a glycine method, comprising the steps of:

[0041] 1) Pretreatment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com