A method for comprehensive utilization of waste liquid containing magnesium and/or calcium in the separation process of rare earth smelting and separation

A separation process and rare earth technology, applied in chemical instruments and methods, magnesium oxide, chlorine/hydrogen chloride, etc., can solve the problems of accelerating water eutrophication process, sodium chloride high-salt wastewater pollution, ammonia nitrogen consumption of dissolved oxygen, etc., to achieve Effects of relaxing pyrolysis conditions, reducing sales pressure, and reducing heat energy consumption

Active Publication Date: 2022-06-10

GRIREM ADVANCED MATERIALS CO LTD

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the presence of ammonia nitrogen and chloride ions in ammonium chloride wastewater, if the wastewater is discharged directly, it will cause serious pollution to the water body

Ammonia nitrogen consumes dissolved oxygen in the water body and accelerates the eutrophication process of the water body; moreover, ammonia nitrogen will be transformed into nitrate nitrogen and nitrite nitrogen under the action of microorganisms in the water, which is toxic to the human body

Some enterprises use sodium carbonate instead of ammonium bicarbonate as a precipitant to produce rare earth carbonates or oxides to eliminate ammonia nitrogen wastewater pollution, but the cost has more than doubled, and it has caused sodium chloride and high-salt wastewater pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Login to View More

Abstract

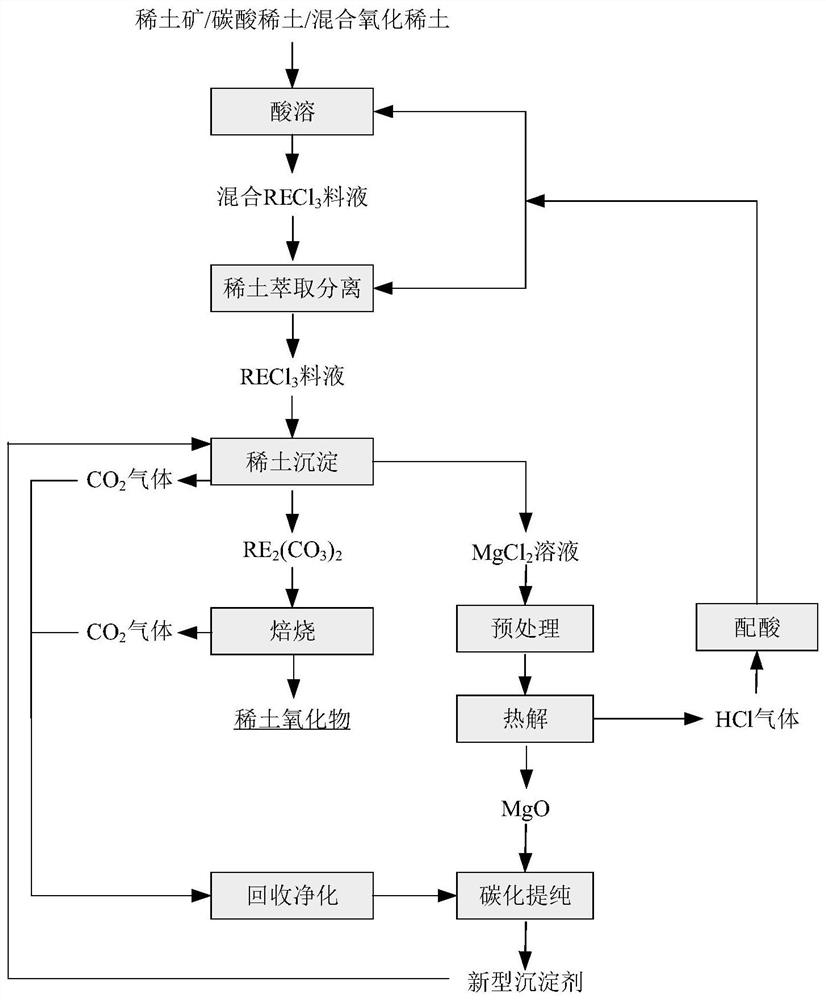

A method for comprehensive utilization of waste liquid containing magnesium and / or calcium in the rare earth smelting and separation process, wherein the waste liquid containing magnesium and / or calcium produced in the separation process of rare earth smelting and separation is pyrolyzed to obtain magnesium oxide and / or calcium oxide solids and gas containing hydrogen chloride , the obtained hydrogen chloride gas is used for acid dissolution or rare earth extraction and separation after acid production, and the obtained magnesium oxide and / or calcium oxide are directly returned for rare earth precipitation crystallization or purified by pulping and carbonization as a new precipitant for rare earth precipitation crystallization . The treatment method of the present invention has short process flow and low energy consumption, and at the same time, the obtained products and by-products are combined with the rare earth smelting and separation process to realize resource recycling, and there is basically no waste water and waste gas discharge in the whole process.

Description

A comprehensive utilization method of magnesium and / or calcium-containing waste liquid in rare earth smelting and separation process technical field The invention belongs to the field of waste liquid treatment, be specifically related to a kind of rare earth smelting separation process containing magnesium and / or calcium waste liquid. Comprehensive utilization method. Background technique [0002] my country is recognized as the world's largest country with the most abundant rare earth resources. After nearly 50 years of continuous development, it has now been completed. The world's largest rare earth industry system has become the world's largest rare earth producer, exporter and consumer. at the same time, my country's rare earth smelting and separation industry has also achieved a transformation from small to large, from weak to strong. China's rare earth production in 1980 There are only thousands of tons, and as of 2016, the output has reached 105,000 tons, acco...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B3/44C22B59/00C01B7/03C01F5/02C01F11/02

CPCC22B59/00C22B3/44C01F5/02C01F11/02C01B7/035C01P2006/80Y02P10/20

Inventor 王猛冯宗玉黄小卫陈世梁徐旸孙旭夏超崔大立余宗鹤

Owner GRIREM ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com