Method for producing compound fertilizer from allantoin wastewater

A technology of allantoin and compound fertilizer, applied in fertilization device, fertilizer mixture, application and other directions, can solve the problems of high treatment cost, difficult waste water treatment, reduction of comprehensive production cost of allantoin, etc. Economic and social benefits, and the effect of solving outstanding environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

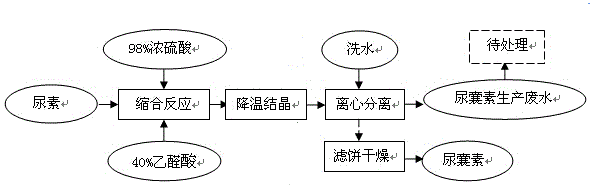

[0056] Embodiment 1, the preparation of allantoin:

[0057]Put 1600kg of 50wt% glyoxylic acid into a 5000L condensation reaction kettle (add 400kg of water to dilute it into a 40wt% aqueous solution), start stirring, add 2560kg of urea, add 423kg of 98% concentrated sulfuric acid, heat up to 80°C, and cool at 78-80°C For the heat preservation reaction, the timing starts when the solid is precipitated. After 1 hour of heat preservation, the temperature is lowered to 70-72°C, and the heat preservation reaction is continued at 70-72°C for 17 hours. Then lower it to 30°C, centrifuge, wash the filter cake with water until the pH of the lotion is 7.0, spin dry, take the filter cake to dry, and obtain 1280 kg of allantoin finished product. The filtrate and the lotion are combined and mixed evenly, which is called allantoin production wastewater, weighing and measuring 14.72 tons (equivalent to about 11.5 tons of wastewater produced per 1 ton of allantoin finished product), which is r...

Embodiment 2

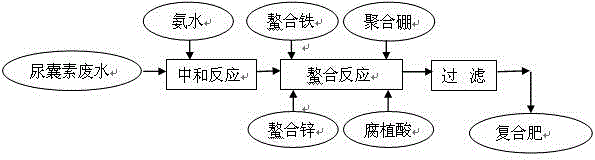

[0063] Embodiment 2 discloses a kind of method that allantoin waste water produces compound fertilizer, and the method comprises the following steps:

[0064] (1) Neutralization reaction: 1500 kg of allantoin production waste water obtained in the above-mentioned embodiment 1 is dropped into a clean 2000L glass-lined reactor, start stirring, open the jacket of the reactor to circulate cooling water, and control the temperature in the kettle to 20-22°C. Use 25.0wt% ammonia solution to neutralize the allantoin production wastewater, adjust the pH value to 6.5, and consume 33.4kg of ammonia water (the amount is based on the pH value reaching the standard).

[0065] (2) Chelation reaction: Add 60kg of chelated iron (EDDHA-FeNa) and polymerized boron (Na 2 B 8 o 13 4H 2 O) 30kg, chelated zinc (Na 2 Zn-EDTA) 22.5kg and humic acid 15kg, carry out chelation reaction, the reaction temperature is controlled at 20-22 ℃, and the reaction time is 4 hours. Chelation reaction feed mass ...

Embodiment 3

[0071] Embodiment 3 discloses a kind of method that allantoin waste water produces compound fertilizer, and the method comprises the following steps:

[0072] (1) Neutralization reaction: 1500 kg of allantoin production waste water obtained in the above-mentioned embodiment 1 is dropped into a clean 2000L glass-lined reactor, start stirring, open the jacket of the reactor to circulate cooling water, and control the temperature in the kettle to 21-23° C. Use 22.5% ammonia solution to neutralize the allantoin production wastewater, adjust the pH value to 6.8, and consume 38.2kg of ammonia water (the amount is based on the pH value reaching the standard).

[0073] (2) Chelation reaction: Add 75kg of chelated iron (EDDHA-FeNa) and polymerized boron (Na 2 B 8 o 13 4H 2 O) 40.5kg, chelated zinc (Na 2 Zn-EDTA) 30kg and humic acid 22.5kg, carry out chelation reaction, the reaction temperature is controlled at 21-23 ℃, and the reaction time is 5 hours. Chelation reaction feed rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com