Unsaturated carboxylic acid in-situ polymerization-crosslinking formaldehyde-free non-iron finishing method of cellulose fiber fabric

A technology of cellulose fiber and non-ironing finishing, which is applied in fiber processing, textiles and papermaking, etc. It can solve the problems of high temperature and long time, and achieve the effects of reduced energy consumption, simple operation and comprehensive cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

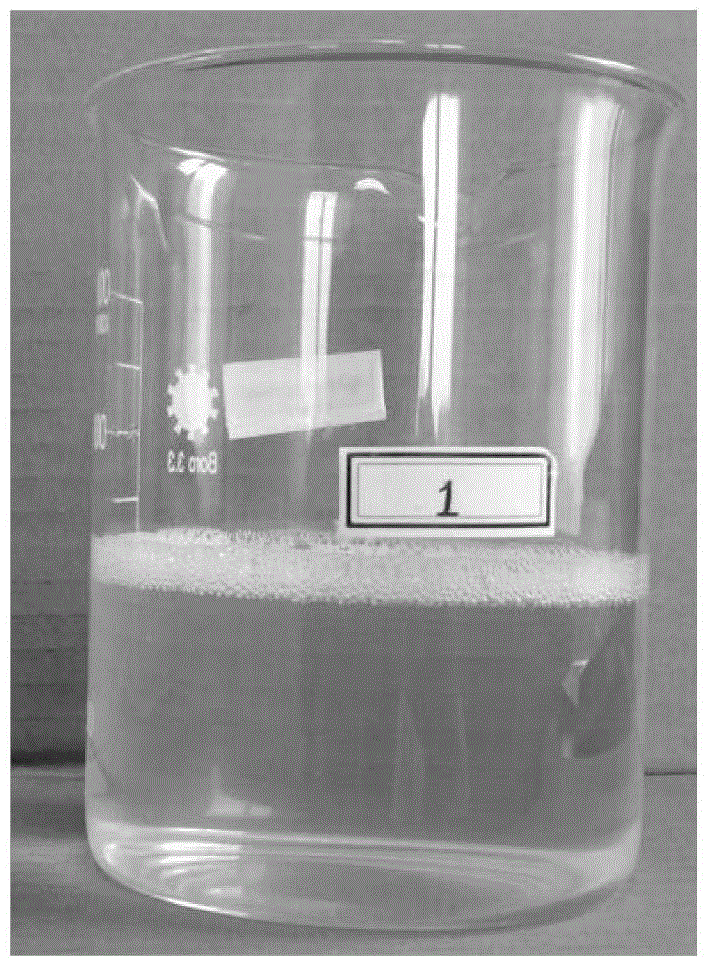

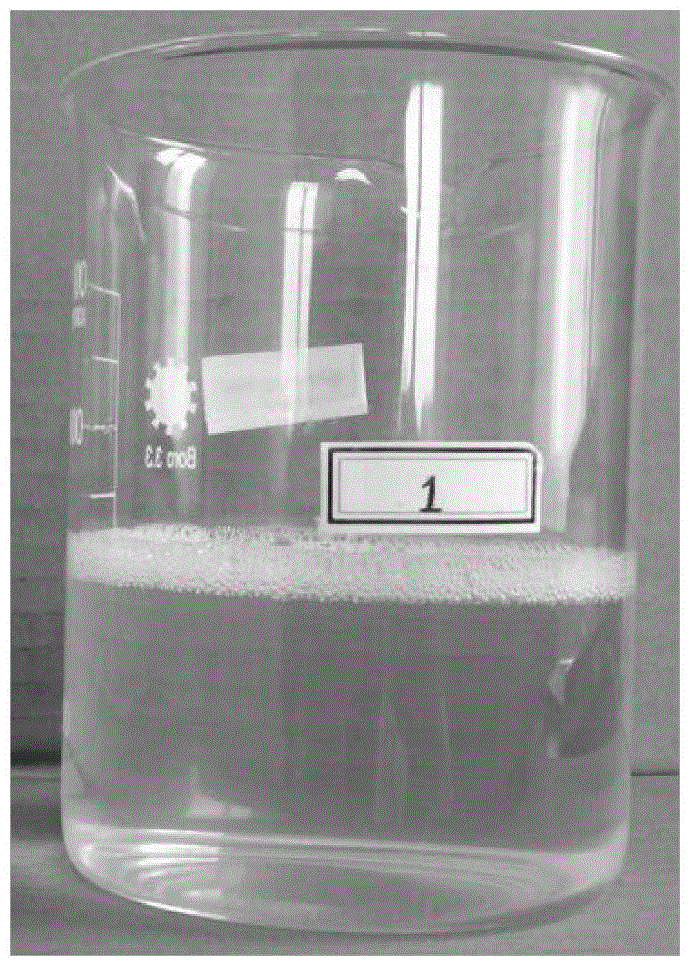

[0029] Formaldehyde-free preparation of non-iron finishing solution: at room temperature, the total amount of 10% (molar ratio 1:1) of maleic acid and itaconic acid, 8.5% catalyst potassium hypophosphite (with unsaturated carboxylic acid molar ratio of 1:1), 0.3% initiator potassium persulfate, 2% silicone softener SIO (because the silicone softener SIO is an opaque milky white liquid, for the convenience of observing the appearance of the finishing liquid, the softener is added last) and 0.2 % penetrant JFC is added to an appropriate amount of water, mixed, stirred and dissolved to obtain a uniform and stable non-ironing finishing solution. The pH value of the finishing solution was adjusted to 2.0 with sodium hydroxide. The appearance of the finishing solution before adding the softener SIO can be seen Figure 1a and 1b .

[0030] Use the prepared finishing liquid to carry out non-ironing finishing on the white Oxford textile semi-finished products. The process flow is: t...

Embodiment 2

[0032] Formaldehyde-free preparation of non-iron finishing solution: at room temperature, the total amount of 10% (molar ratio 1:1.5) of maleic acid and itaconic acid, 8.5% catalyst potassium hypophosphite (with unsaturated carboxylic acid molar ratio of 1:1), 0.3% initiator potassium persulfate, 2% silicone softener SIO and 0.3% penetrant JFC are added to an appropriate amount of water, mixed, stirred and dissolved to obtain a uniform and stable non-ironing finishing solution. The pH value of the finishing solution was adjusted to 2.0 with sodium hydroxide.

[0033] Use the prepared finishing liquid to carry out non-ironing finishing on the yarn-dyed check cloth. The technological process is: two dipping and two rolling (liquid retention rate 85%)→drying (90°C×5min)→baking (180°C×2min). The properties of the fabric after finishing are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com