Preparation method of modified calcium carbonate

A calcium carbonate and modification technology, applied in the field of calcium carbonate, can solve the problems of easy falling off of starch and low paper strength, and achieve the effect of improving retention rate and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

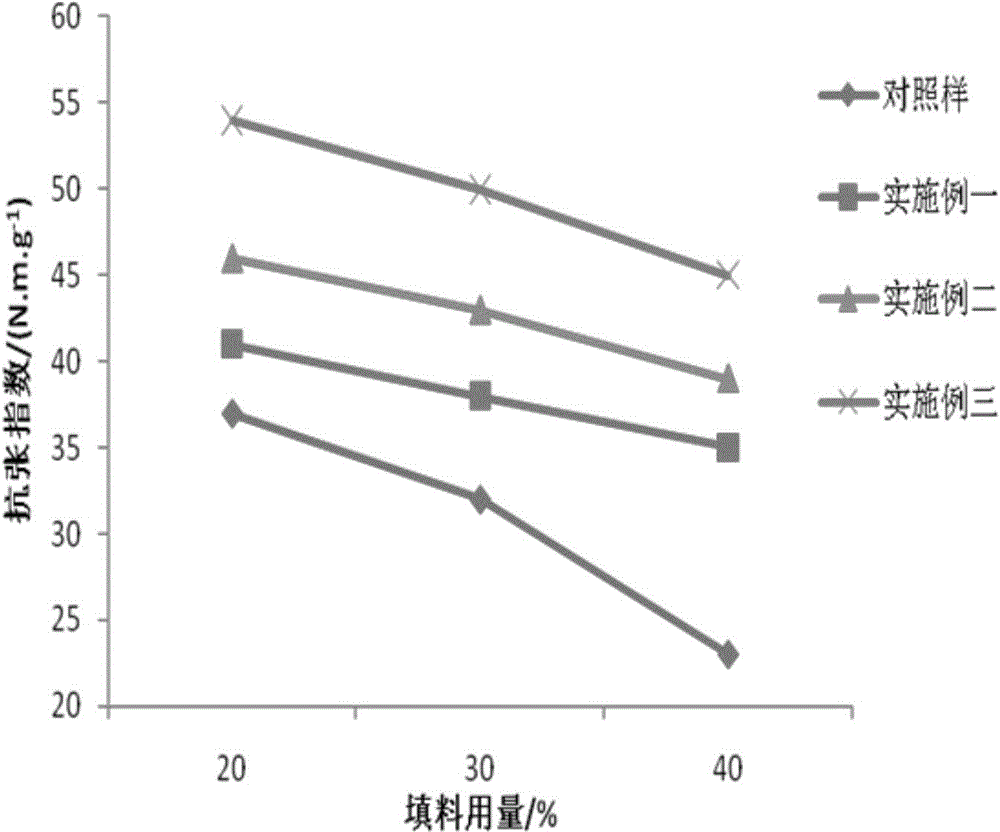

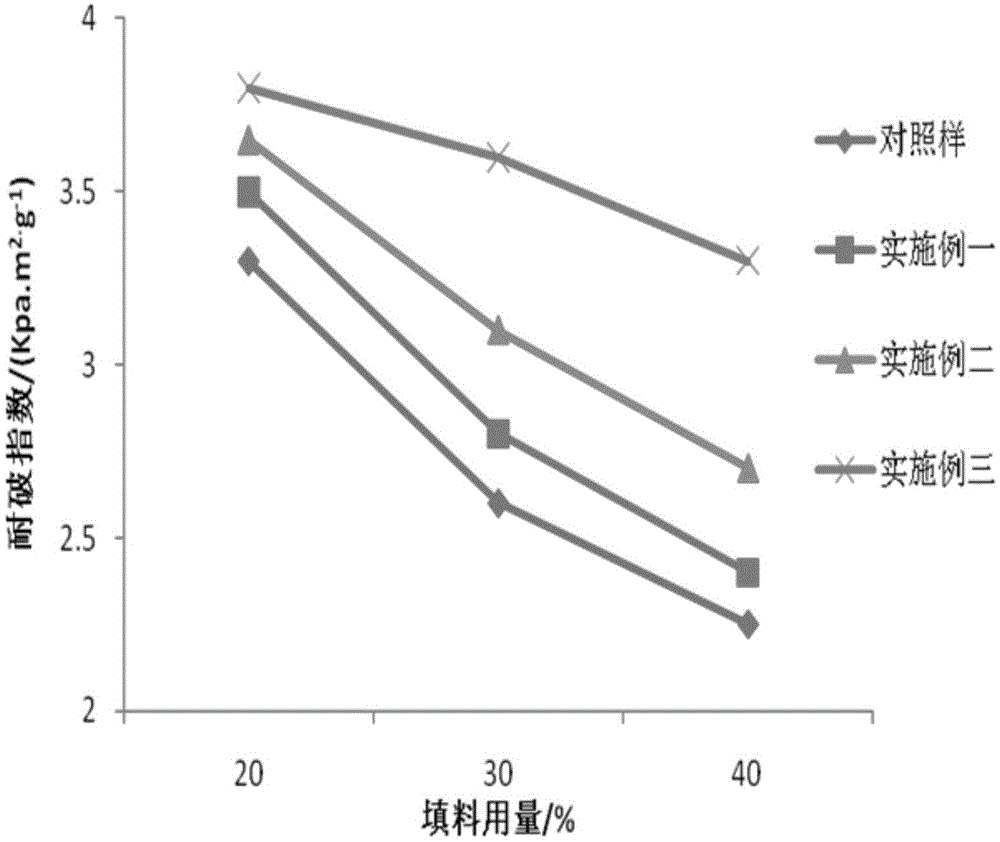

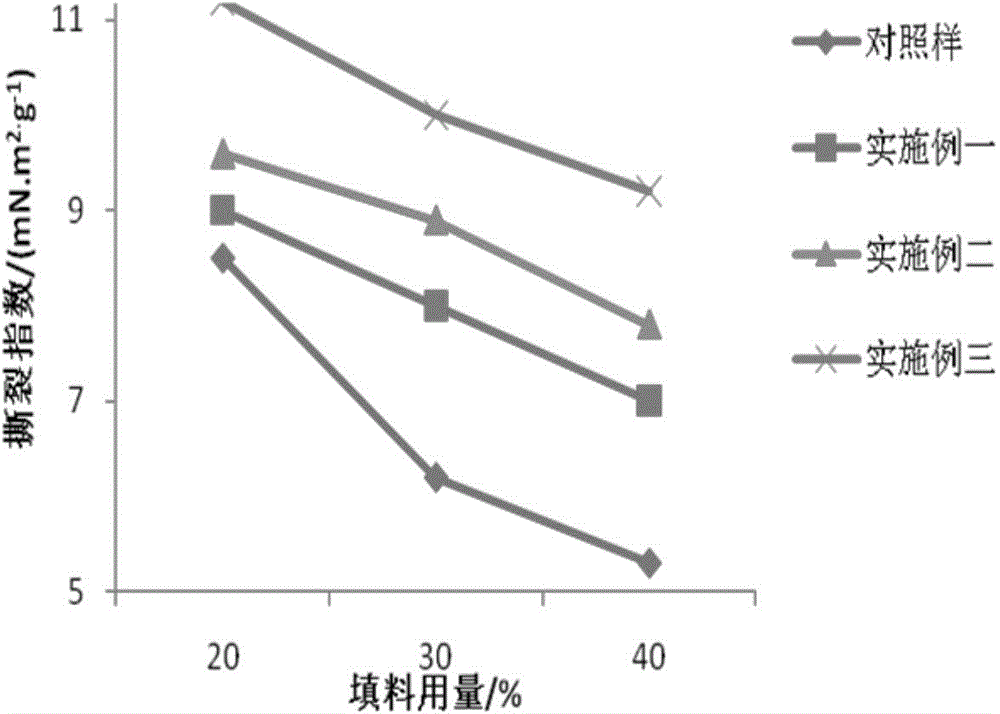

Embodiment 1

[0031] Embodiment 1: preparation steps:

[0032] ①Put the three-neck flask with a dry weight of 10g of calcium carbonate suspension in a constant temperature water bath, and stir the suspension at 450rpm until it reaches a temperature of 85°C;

[0033] ②Add 10g of raw cornstarch of the same quality to a three-necked bottle, and stir for 60 minutes;

[0034] ③Add 1g of stearic acid, and adjust the pH value to 11 with NaOH solution;

[0035] ④Add 2g of cis-12hydroxyoctadecene-3-methyl-imidazole hexafluorophosphate and tetrafluoroboric acid-1-butyl-3-methylimidazole compound, the ratio is 3:2, stir for 85 Keep warm for 30min at ℃;

[0036] ⑤ Adjust the pH of the solution to 5 with hydrochloric acid, stir for 1 min and then stand still for 30 s, centrifuge the mixture suspension with a centrifuge tube, wash the precipitate with distilled water, and collect the complex on filter paper.

Embodiment 2

[0037] Embodiment 2: preparation steps:

[0038] ①Put the three-neck flask with a dry weight of 10g of calcium carbonate suspension in a constant temperature water bath, and stir the suspension at 450rpm until it reaches a temperature of 85°C;

[0039] ②Add 10g of raw cornstarch of the same quality to a three-necked bottle, and stir for 60 minutes;

[0040] ③Add 1g of stearic acid, and adjust the pH value to 11 with NaOH solution;

[0041] ④Add 4g of cis-12hydroxyoctadecene-3-methyl-imidazole hexafluorophosphate and tetrafluoroboric acid-1-butyl-3-methylimidazole compound, the ratio is 3:2, stir for 85 Keep warm for 30min at ℃;

[0042] ⑤ Adjust the pH of the solution to 5 with hydrochloric acid, stir for 1 min and then stand still for 30 s, centrifuge the mixture suspension with a centrifuge tube, wash the precipitate with distilled water, and collect the complex on filter paper.

Embodiment 3

[0043] Embodiment 3: preparation steps:

[0044]①Put the three-neck flask with a dry weight of 10g of calcium carbonate suspension in a constant temperature water bath, and stir the suspension at 450rpm until it reaches a temperature of 85°C;

[0045] ②Add 10g of raw cornstarch of the same quality to a three-necked bottle, and stir for 60 minutes;

[0046] ③Add 1g of stearic acid, and adjust the pH value to 11 with NaOH solution;

[0047] ④Add 6g of cis-12hydroxyoctadecene-3-methyl-imidazole hexafluorophosphate and tetrafluoroboric acid-1-butyl-3-methylimidazole compound, the ratio is 3:2, stir for 85 Keep warm for 30min at ℃;

[0048] ⑤ Adjust the pH of the solution to 5 with hydrochloric acid, stir for 1 min and then stand still for 30 s, centrifuge the mixture suspension with a centrifuge tube, wash the precipitate with distilled water, and collect the complex on filter paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com