Horizontal warehouse of heat preservation steel structure

A technology for flat warehouses and steel structures, applied in thermal insulation, building components, building structures, etc., to achieve the effects of reducing the risk of warehouse expansion, saving materials, and reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

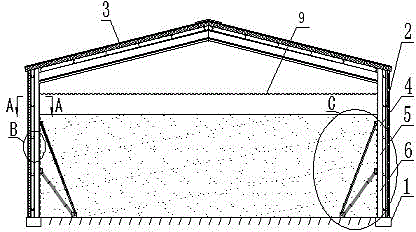

[0029] An insulated steel structure one-story warehouse, which consists of a foundation 1. The insulated steel structure one-story warehouse includes a warehouse roof 3 and a warehouse body 2. The bottom of the insulated steel structure one-story warehouse is connected to the foundation. The warehouse body It includes a column frame 4 and a thermal insulation wall 5, and a pressure bearing plate 6 is fixed inside the column frame.

Embodiment 2

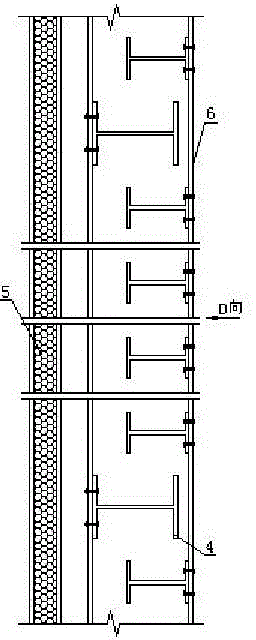

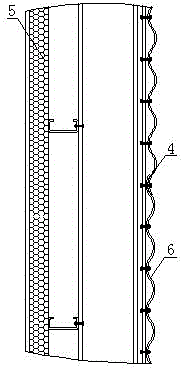

[0031] In the one-story warehouse with thermal insulation steel structure described in Example 1, the pressure-bearing plate is connected to the pressure-bearing truss, and the pressure-bearing plate is a corrugated steel plate or a polygonal plate with a thickness of 1.2-5mm, and when used within the thickness range, Thinning from bottom to top.

Embodiment 3

[0033] In the one-story storehouse with thermal insulation steel structure described in Embodiment 1 or 2, the height of the pressure bearing plate is the height of the grain loading line, and the pressure bearing plate is detachably connected to the pressure bearing truss by bolts, or connected to the pressure bearing truss by welding. The truss is fixedly connected, the pressure-bearing truss includes a vertical column and a horizontal beam, one end of the cable-stayed beam 7 is fixed on the vertical column or the horizontal beam, and the other end is fixed on the ground basically.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com