Blade of high-power horizontal shaft ocean current energy electric generator and manufacturing method thereof

A horizontal axis, ocean current energy technology, used in hydroelectric power generation, machine/engine, final product manufacturing, etc., can solve problems such as blade corrosion damage, cavitation, and entanglement of suspended fishing nets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

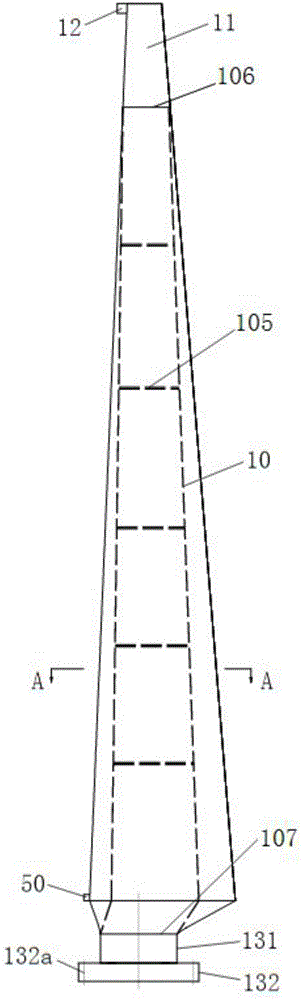

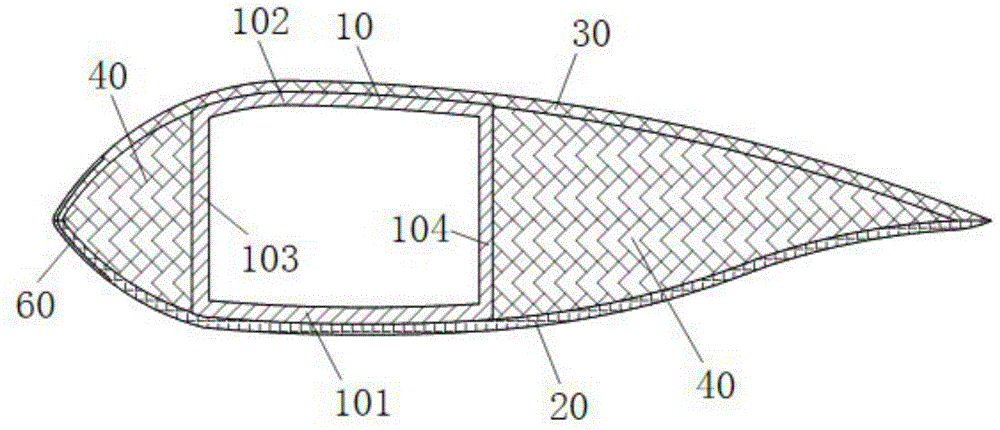

[0053] refer to figure 1 , image 3 , Figure 5 , Figure 6 , Figure 13-16 : the blade of the high-power horizontal axis ocean current energy generator, including a hollow metal girder 10, the metal girder 10 gradually widens from top to bottom, and several horizontal webs 105 to strengthen the rigidity are welded at intervals on the metal girder 10, the metal girder The cross section of 10 is type, the top of the metal girder 10 is welded with a metal blade tip 11, the metal blade tip 11 is fixed with a first net cutter 12, and the metal blade tip 11 and the first net cutter 12 are integrally manufactured by a four-axis linkage machine tool, or the metal blade The tip 11 is integrally manufactured by a four-axis linkage machine tool, and the first mesh cutter 12 is welded on the metal blade tip 11, and the metal blade root 13 is welded to the bottom of the metal girder 10, and the metal blade root 13 is integrally manufactured by a four-axis linkage machine tool. The m...

Embodiment 2

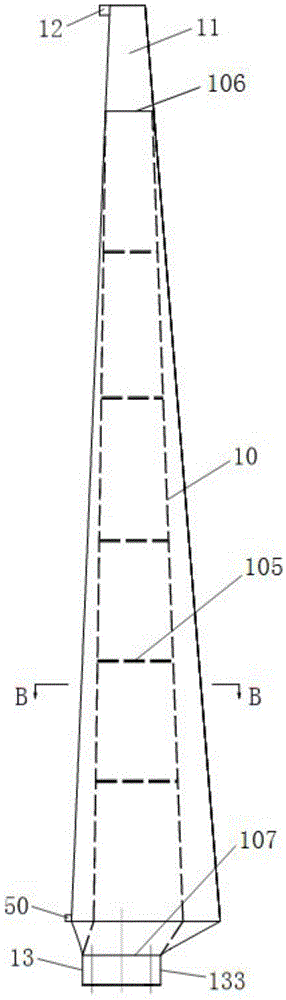

[0077] refer to figure 2 , Figure 4 , Figure 5 , Figure 13-16 : This embodiment also adopts the cross section as type metal girder 10, the difference between the present embodiment and the first embodiment is that the metal blade root 13 is a threaded hole 133 connected with the hub 80 of the current energy generator, the threaded hole 133 is an internal threaded hole, and the internal thread The hole is threadedly connected with the external threaded hole on the hub 80 of the ocean current energy generator.

Embodiment 3

[0079] refer to Figure 7 , Figure 8 , Figure 13-16 : The difference between this embodiment and Embodiment 1 is: the cross section of the metal girder 10 is type, using the The structural diagram of the blade of the metal girder with cross-section is as follows Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com