Preparation method of Fe3N polycrystalline film based on GaN substrate

A thin film preparation and substrate technology, applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve the problems of slow growth rate of N thin film, unfavorable analysis, etc., to achieve mass production and simple process reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

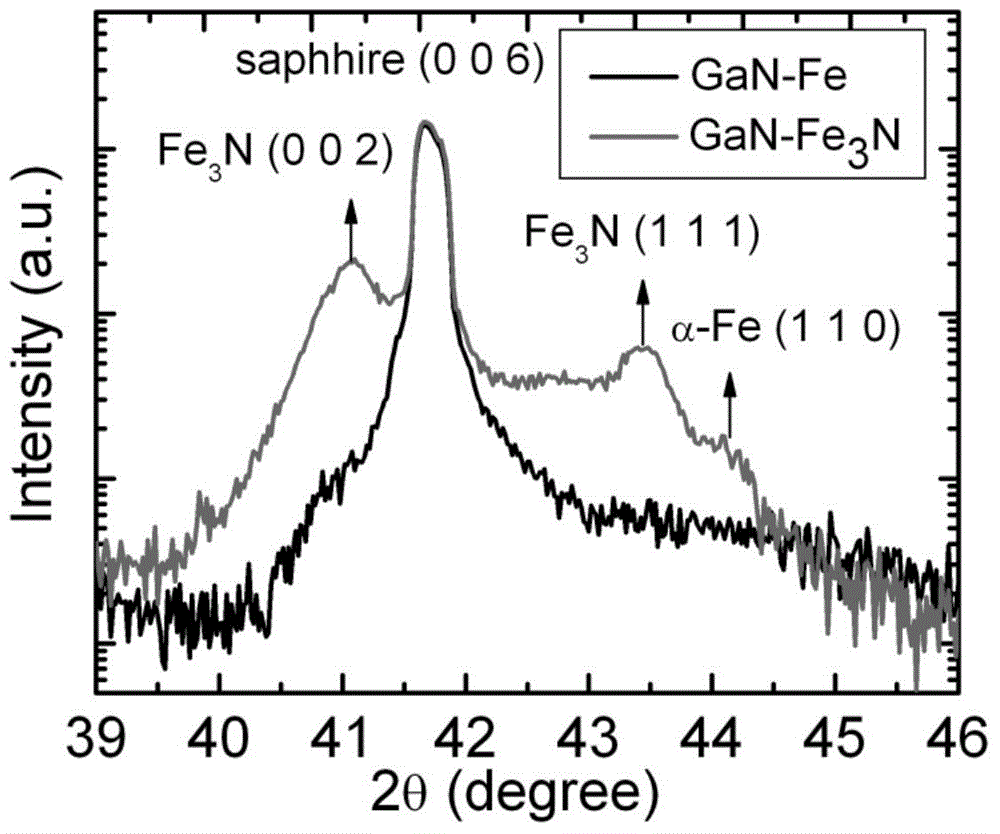

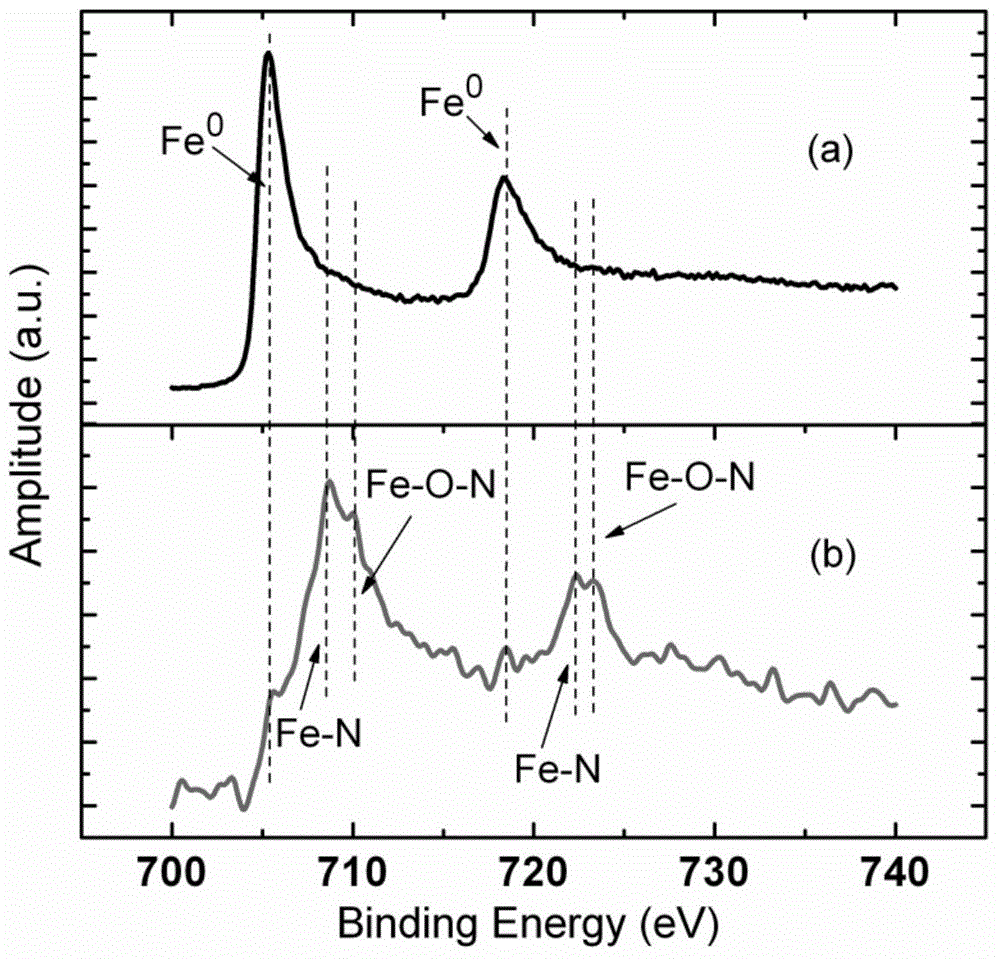

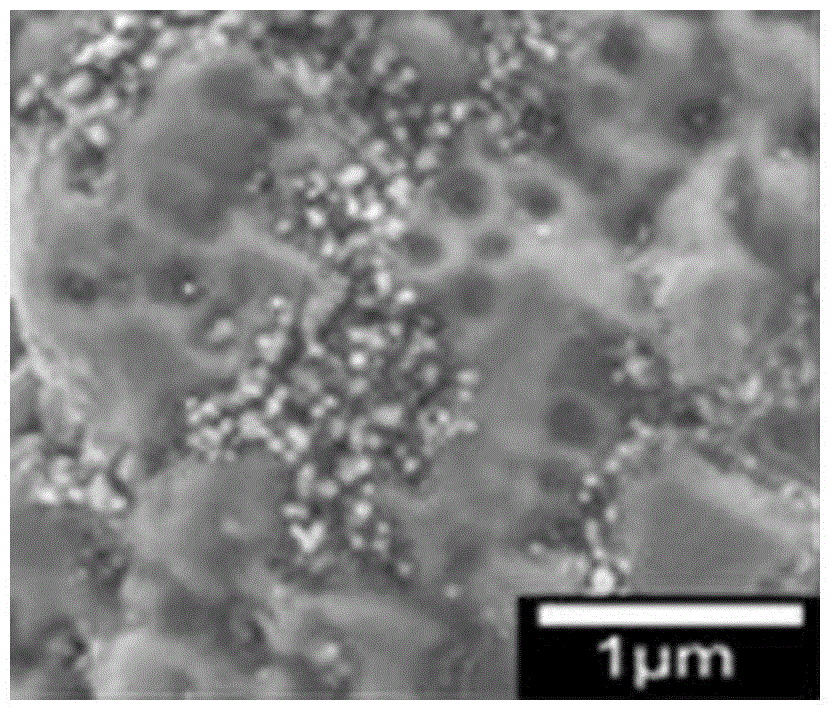

[0029] A kind of Fe based on GaN substrate of the present embodiment 3 N polycrystalline film preparation method, comprises the following steps

[0030] (1) A GaN film with a thickness of 3 microns is used as a substrate, and it is cleaned with alcohol in an ultrasonic cleaner for 5 minutes. The GaN film is an unintentionally doped single-crystal film.

[0031] (2) A layer of amorphous iron film is sputtered on the GaN substrate in step 1 by magnetron sputtering, wherein the purity of the iron target is not lower than 99.99%. The condition is the cavity base pressure: 2×10 -5 Pa, sputtering power: 100W, sputtering time: 1800 seconds.

[0032] (3) Put the sample obtained in step 2 into a nitriding annealing furnace for nitriding. The conditions are temperature: 900° C., carrier gas: nitrogen, flow rate of ammonia: 4 slm, and time: 3.5 hours.

[0033] (4) The sample obtained in step 3 was etched by RIE for 18 minutes.

[0034] (5) Etch the sample obtained in step 4 with ICP...

Embodiment 2

[0037] A kind of Fe based on GaN substrate of the present embodiment 3 N polycrystalline film preparation method, comprises the following steps

[0038] (1) A GaN thin film with a thickness of 3 microns is used as a substrate, and it is cleaned with alcohol in an ultrasonic cleaner for 3 minutes.

[0039] (2) A layer of amorphous iron film is sputtered on the GaN substrate in step 1 by magnetron sputtering, wherein the purity of the iron target is not lower than 99.99%. The condition is the cavity base pressure: 1×10 -5 Pa, sputtering power: 100W, sputtering time: 1200 seconds.

[0040] (3) Put the sample obtained in step 2 into a nitriding annealing furnace for nitriding. The conditions are temperature: 800° C., carrier gas: nitrogen, flow rate of ammonia: 4 slm, and time: 3.5 hours.

[0041] (4) The sample obtained in step 3 was etched by RIE for 15 minutes.

[0042] (5) The sample obtained in step 4 was etched by ICP for 20 seconds to obtain a GaN substrate-based Fe3N ...

Embodiment 3

[0045] A kind of Fe based on GaN substrate of the present embodiment 3 N polycrystalline film preparation method, comprises the following steps

[0046] (1) A GaN thin film with a thickness of 3 microns is used as a substrate, and it is cleaned with alcohol in an ultrasonic cleaner for 8 minutes.

[0047](2) A layer of amorphous iron film is sputtered on the GaN substrate in step 1 by magnetron sputtering, wherein the purity of the iron target is not lower than 99.99%. The condition is the cavity base pressure: 3×10 -5 Pa, sputtering power: 100W, sputtering time: 2400 seconds.

[0048] (3) Put the sample obtained in step 2 into a nitriding annealing furnace for nitriding. The conditions are temperature: 1000° C., carrier gas: nitrogen, flow rate of ammonia: 4 slm, and time: 3.5 hours.

[0049] (4) The sample obtained in step 3 was etched by RIE for 20 minutes.

[0050] (5) The sample obtained in step 4 was etched by ICP for 40 seconds to obtain a GaN substrate-based Fe3N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com