Structure of self-mode-locked pulses in compressed fiber lasers

A fiber laser, self-mode-locking technology, applied to the structure/shape of lasers, active media, laser components, etc., can solve problems such as relatively expensive, increased laser weight and volume, and system complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

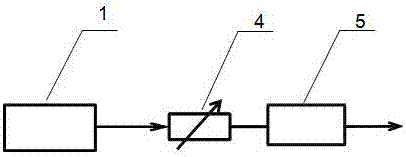

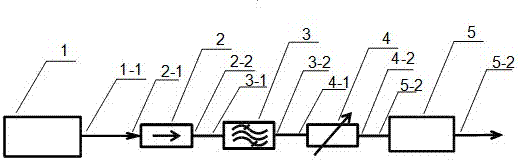

[0016] Implementation mode one: if figure 1 As shown, the present embodiment is a single-stage fiber amplifier processing stage, and the fiber laser output end 1-1 of the fiber laser 1 is connected to the adjustable optical attenuator input end 4-1 of the adjustable optical attenuator 4 in the processing stage, which can be The output port 4-2 of the dimming attenuator is connected to the fiber amplifier input port 5-1 of the fiber amplifier 5, and the fiber amplifier output port 5-2 is connected to the input port of the operating system; 2 Connect the adjustable optical attenuator to avoid the measurement equipment being damaged by high-power laser (use an optical power meter to measure the optical power value), the output end of the adjustable optical attenuator is connected to the input end of the optical receiver, and the electrical output port of the optical receiver is connected to the oscilloscope . Adjust the adjustable optical attenuator 4 before the fiber amplifier ...

Embodiment approach 2

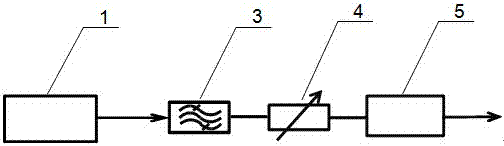

[0017] Implementation mode two: if figure 2 , 3 As shown, the present embodiment is an improvement of the single-stage fiber amplifier processing stage, the fiber laser output end 1-1 of the fiber laser 1 is connected to the optical isolator input end 2-1 of the optical isolator 2 in the processing stage, and the optical isolator output The end 2-2 is connected to the optical bandpass filter input end 3-1 of the optical bandpass filter 3, and the optical bandpass filter output end 3-2 is connected to the adjustable optical attenuator input end of the adjustable optical attenuator 4 4-1, the output port 4-2 of the adjustable optical attenuator is connected to the fiber amplifier input port 5-1 of the fiber amplifier 5, and the fiber amplifier output port 5-2 is connected to the input port of the operating system; The output terminal 5-2 of the amplifier is connected to the adjustable optical attenuator to prevent the measuring equipment from being damaged by high-power laser ...

Embodiment approach 3

[0018] Implementation mode three: if image 3 , 4 As shown, the present embodiment is a series connection of multi-stage fiber amplifier processing stages, the fiber laser output end 1-1 of the fiber laser 1 is connected to the first fiber amplifier processing stage 6, and the output end of the first fiber amplifier processing stage 6 is connected to The input end of the second optical fiber amplifier processing stage 7, and so on, the output end of the Nth optical fiber amplifier processing stage 8 is connected to the input end of the application system, and the structure of each processing stage can be combined with figure 1 or figure 2 or image 3 The same as shown; when the measurement equipment needs to be connected, the output port 5-2 of the optical fiber amplifier in the last stage is connected to an adjustable optical attenuator to avoid the measurement equipment being damaged by high-power laser (use an optical power meter to measure the optical power value), adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com