Metal film etching solution composition and etching method using the same

A technology of composition and etching solution, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of poor etching profile, poor stability, and insufficient stability, and achieve excellent etching profile, excellent stability, and etching speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5、 comparative example 1~ comparative example 5

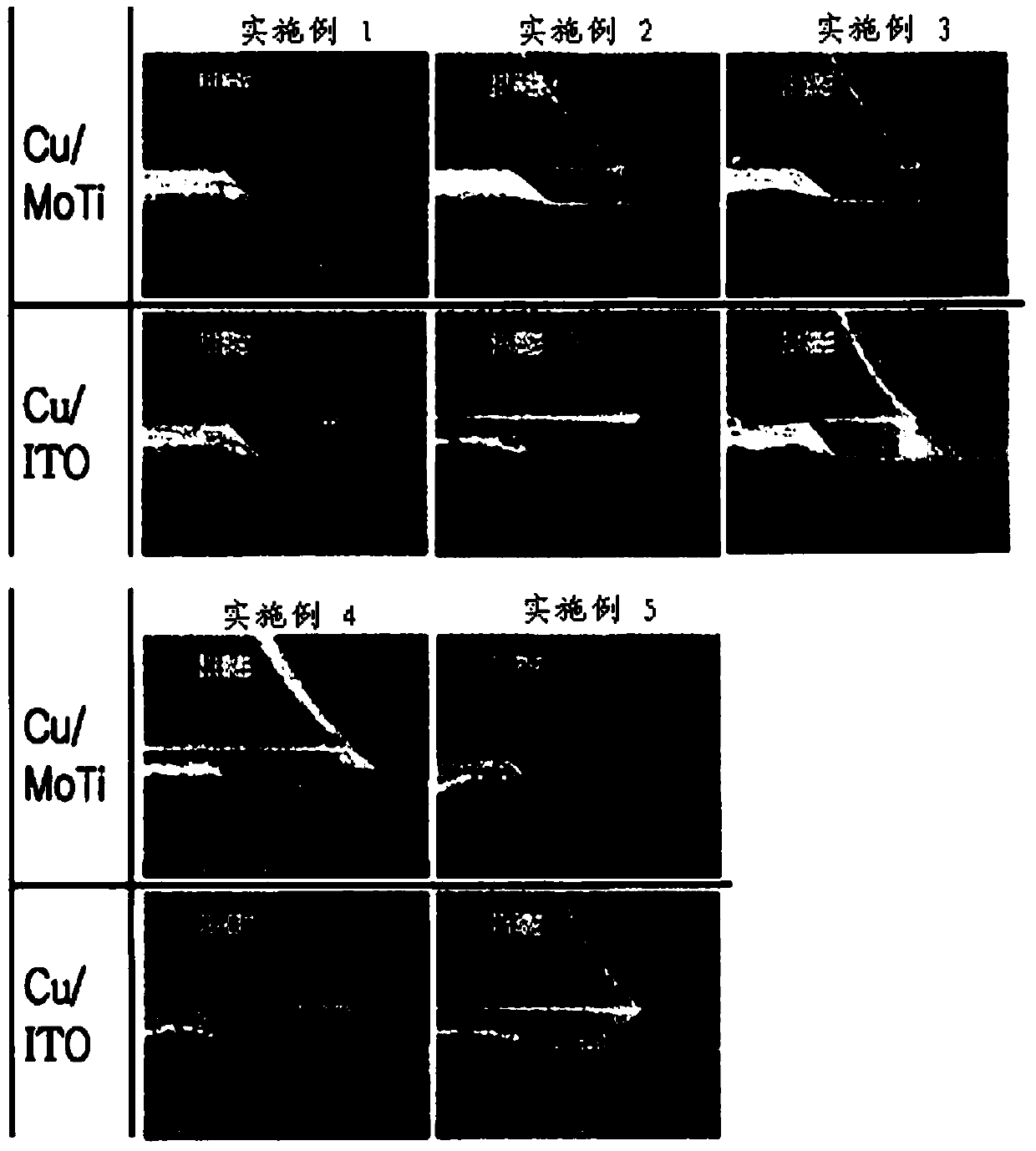

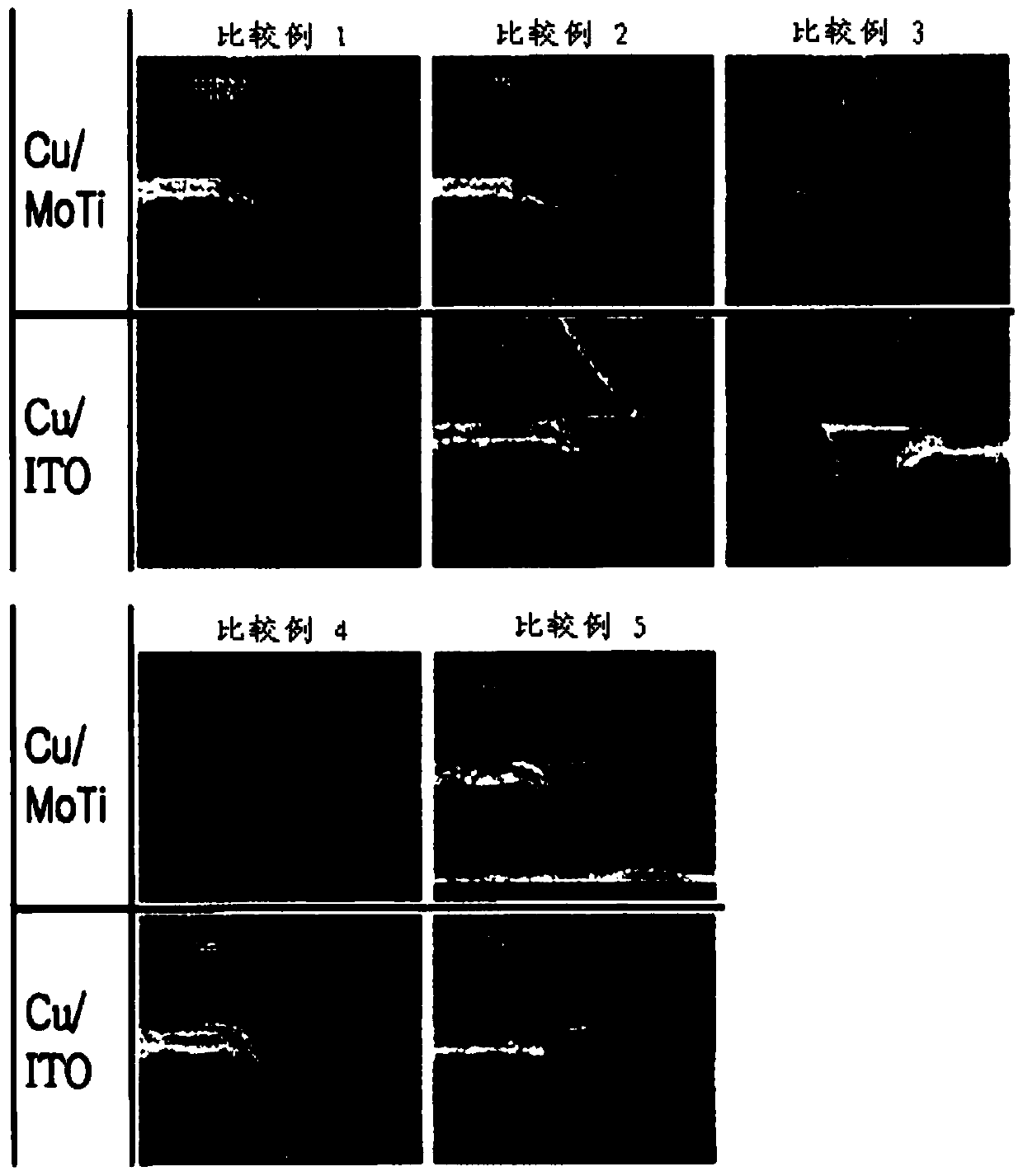

[0030] [Example 1-Example 5, Comparative Example 1-Comparative Example 5] Preparation and evaluation of etching solution composition

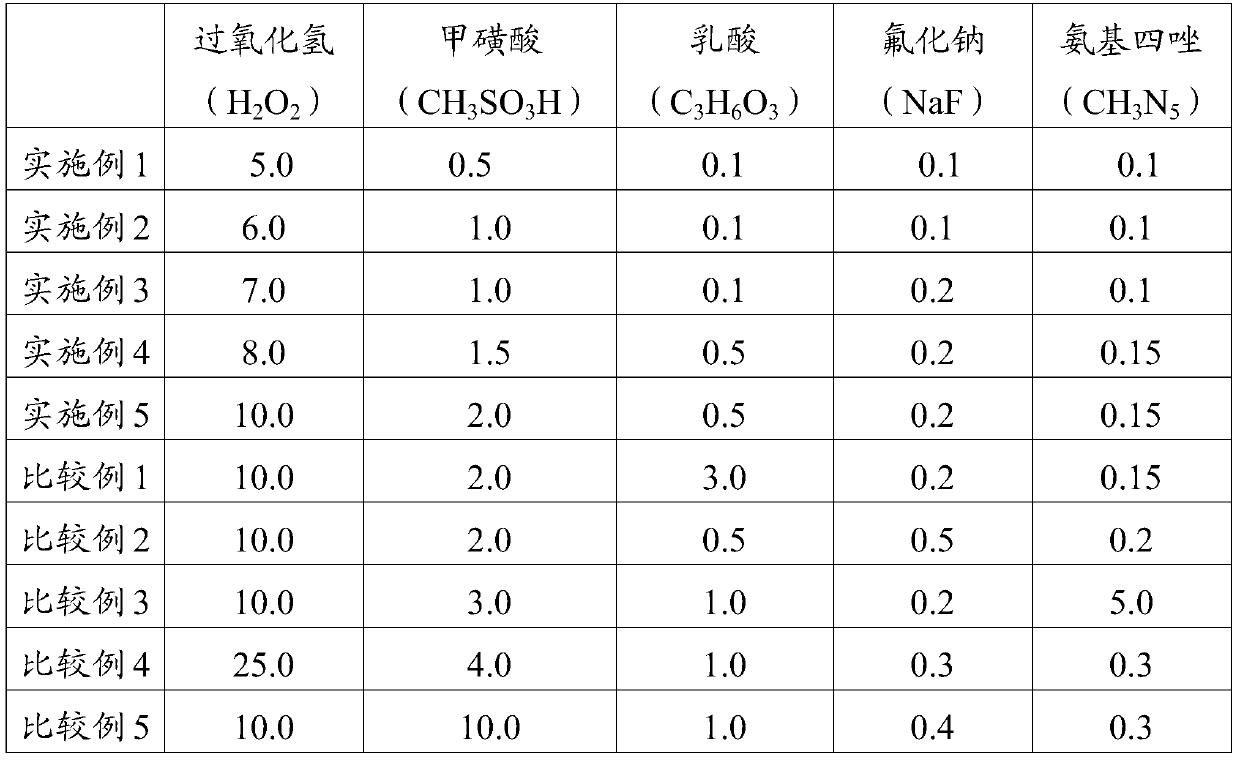

[0031] In order to evaluate the etching performance of the etching liquid composition, the etching liquid composition (embodiment 1~embodiment 5, comparative example 1~comparative example 5) was prepared, and described etching liquid composition comprises the content shown in following table 1 ( Unit: weight % of hydrogen peroxide (H 2 o 2 ), methanesulfonic acid (MSA, CH 3 SO 3 H), lactic acid (lactic acid, C 3 h 6 o 3 ), sodium fluoride (NaF), aminotetrazole (ATZ, CH 3 N 5 ), and the remaining weight % of water (deionized water).

[0032] Table 1 [Table 1]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com