The etching composition for etching conductive multi -layer membrane and the etching method using it

A composition and etchant technology, applied in the directions of surface etching compositions, chemical instruments and methods, circuits, etc., can solve problems such as rising demand for metallization layers, and achieve the effects of simplifying production costs and time, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment Embodiment 1

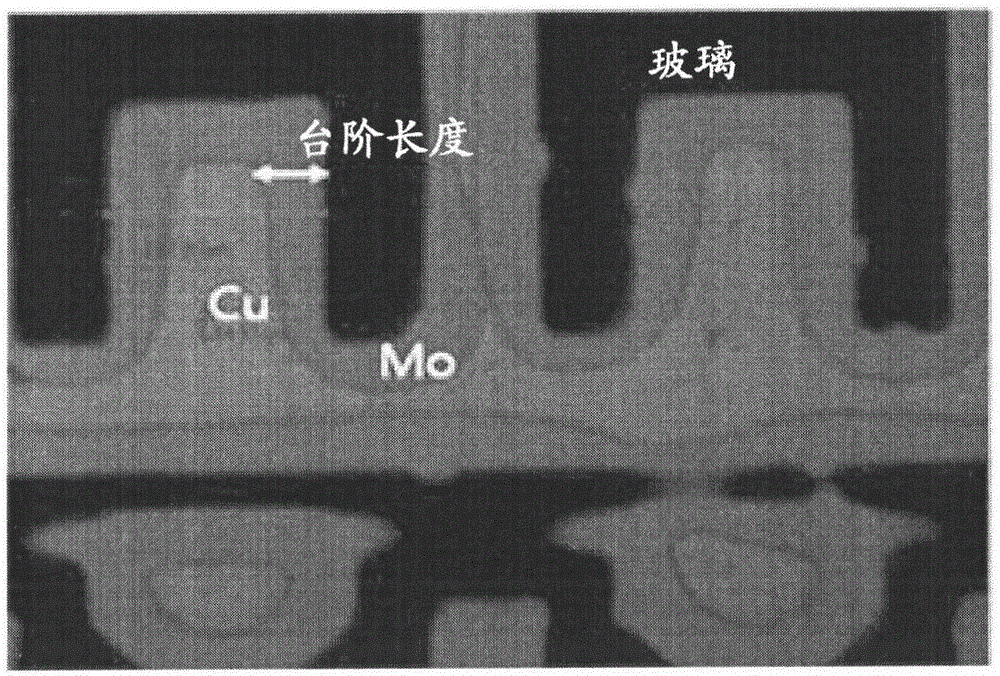

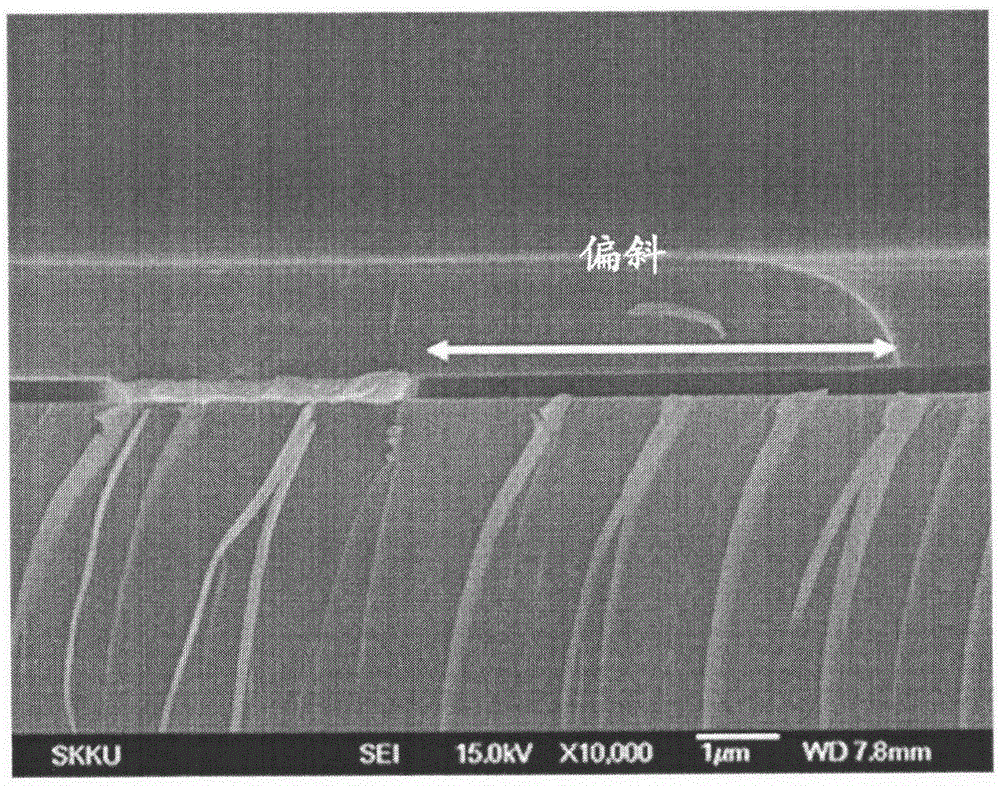

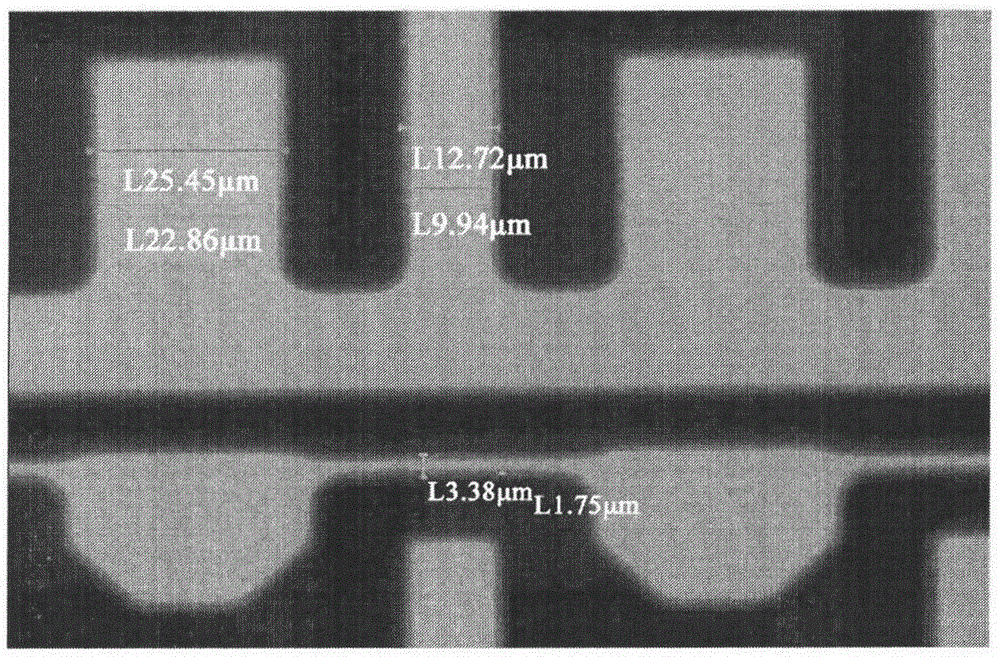

[0058] A Cu / Mo bilayer film was deposited on a substrate and a photoresist (PR) was formed thereon to fabricate a sample. The etchant of Example 1 and Comparative Example 1 were each placed in a spray type etching system (FNSTech.) and heated to 40°C. When the temperature reaches 40±0.1°C, etchant is used to etch the Cu / Mo bilayer film. Etch times were over 50% etch with endpoint detection (EPD). After the etching was completed, the substrate was taken out of the etching system, washed with deionized water, and dried using a hot air dryer. Use a photoresist stripper to remove the photoresist. Critical dimension (CD) skew (etch loss), step length as a width difference between copper and molybdenum layers, and etch residue of etched structures were evaluated using scanning electron microscopy (SEM, TESCAN).

Embodiment 1

[0061]Specifically, KR2006-0082270A discloses an etchant composition for etching metal electrodes to form thin film transistors of flat panel displays. In addition to phosphoric acid, nitric acid, acetic acid, and water, which are components of a typical etchant for etching aluminum, the etchant composition contains an etch rate control agent to form a desired pattern. According to Example 1 of this prior art, the etchant has the following composition:

[0062] h 3 PO 4 (55% by weight)+HNO 3 (8% by weight)+CH3COOH (10% by weight)+(NH 4 ) 2 HPO 4 (2wt%)+CH 3 COONH 4 (2% by weight)+H 2 O (surplus).

[0063] The etching properties of the etchant were tested. The results are shown in Figure 1a and 1b middle.

[0064] specifically, Figure 1a Shows detailed results obtained when applying the etchant of Comparative Example 1 to a Cu / Mo bilayer film as proposed in the prior art (KR2006-0082270A) embodiment comprising phosphoric acid, nitric acid, and at least one additi...

Embodiment 2

[0073] h 3 PO 4 (70% by weight)+HNO 3 (2wt%)+CH 3 COOH (15% by weight) + imidazole (C 3 h 4 N 2 , 0.1 to 0.3% by weight) + distilled water (balance).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com