A U-shaped vibration isolation device with a composite material structure

A composite material and vibration isolation technology, which is applied in the direction of propulsion engine, transportation and packaging, ship construction, etc., to achieve the effects of locking, reducing underwater noise, and improving low-frequency vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

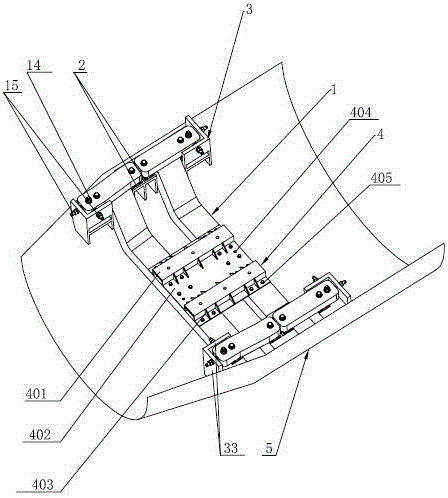

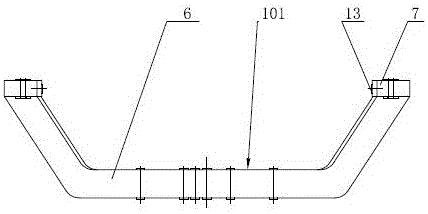

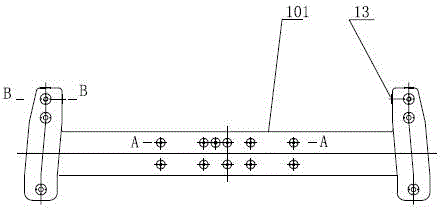

[0022] like figure 1 As shown, a U-shaped vibration isolation device with a composite material structure includes an equipment mounting base 4, the equipment mounting base 4 is fixedly connected with a sandwich composite vibration isolation raft 1, and the sandwich composite vibration isolation raft 1 is at least composed of It is composed of two sandwich composite material structural beams 101 arranged at intervals. In the present invention, there are two sandwich composite material structural beams 101, which are located inside and outside of each sandwich composite material structural beam 101, and are located at the inner and outer sides of each sandwich composite material structural beam 101. The end is connected to the boat hull steel base 3 through the vibration isolator 2. The boat hull steel base 3 is composed of the first layer panel 31, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com