Adhesive and preparation method thereof

An adhesive and fungicide technology, applied in the directions of adhesive additives, adhesive types, starch adhesives, etc., can solve the problems of waste of resources, high cost, and more foam, and reduce the cost of materials and water. The effect of fast decomposition and resource cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

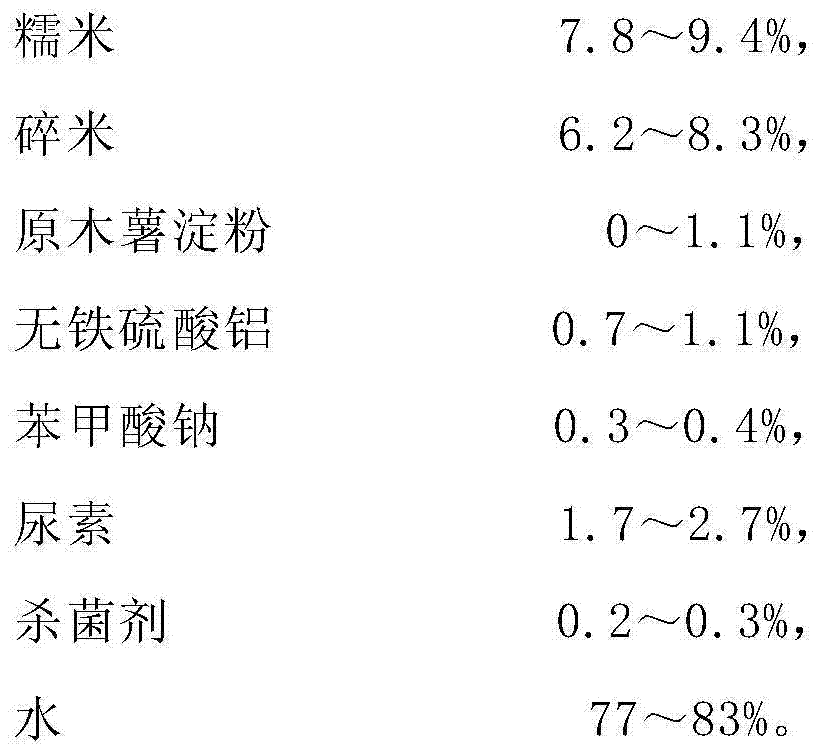

Embodiment 1

[0033] The present embodiment relates to a kind of preparation method of adhesive, described method comprises the steps:

[0034] Step 1. Choose glutinous rice from areas with long sunshine hours; because the longer the sunshine time of glutinous rice, the better the glutinous cohesion, the glutinous rice used includes long glutinous rice, round glutinous rice, broken glutinous rice from any other sources and Glutinous rice flour obtained in any way, mixed with a certain proportion of broken rice;

[0035] Step 2, fully soak the glutinous rice and broken rice with clear water, fully soak the glutinous rice and broken rice with clear water to make the glutinous rice easier to grind into ultra-fine rice slurry, and fully release the adhesive factor rich in glutinous rice;

[0036] Step 3: Rinse the soaked glutinous rice and broken rice in the filter frame to remove the rice bran and fine dust remaining in the processing process, remove the non-sticky free small molecular starch,...

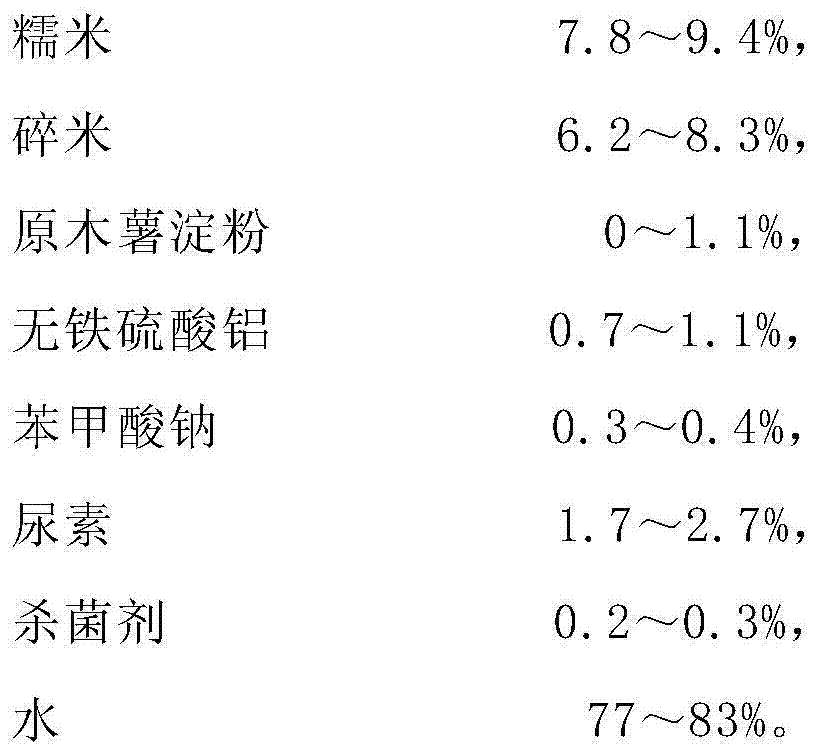

Embodiment 2

[0050] The present embodiment relates to a kind of preparation method of adhesive, described method comprises the steps:

[0051] Step 1. Choose glutinous rice from areas with long sunshine hours; because the longer the sunshine time of glutinous rice, the better the glutinous cohesion, the glutinous rice used includes long glutinous rice, round glutinous rice, broken glutinous rice from any other sources and Glutinous rice flour obtained in any way, mixed with a certain proportion of broken rice;

[0052] Step 2, fully soak the glutinous rice and broken rice with clear water, fully soak the glutinous rice and broken rice with clear water to make the glutinous rice easier to grind into ultra-fine rice slurry, and fully release the adhesive factor rich in glutinous rice;

[0053] Step 3: Rinse the soaked glutinous rice and broken rice in the filter frame to remove the rice bran and fine dust remaining in the processing process, remove the non-sticky free small molecular starch,...

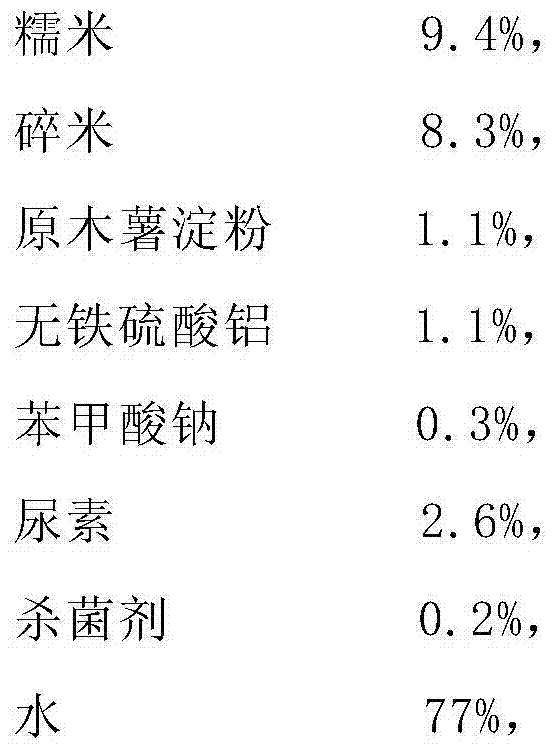

Embodiment 3

[0067] The present embodiment relates to a kind of preparation method of adhesive, described method comprises the steps:

[0068] Step 1. Choose glutinous rice from areas with long sunshine hours; because the longer the sunshine time of glutinous rice, the better the glutinous cohesion, the glutinous rice used includes long glutinous rice, round glutinous rice, broken glutinous rice from any other sources and Glutinous rice flour obtained in any way, mixed with a certain proportion of broken rice;

[0069] Step 2, fully soak the glutinous rice and broken rice with clear water, fully soak the glutinous rice and broken rice with clear water to make the glutinous rice easier to grind into ultra-fine rice slurry, and fully release the adhesive factor rich in glutinous rice;

[0070] Step 3: Rinse the soaked glutinous rice and broken rice in the filter frame to remove the rice bran and fine dust remaining in the processing process, remove the non-sticky free small molecular starch,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com