Method for preparing gluten antihypertensive peptide based on sequential ultrasonic enhanced enzymolysis

A blood pressure-lowering peptide, ultrasonic enhancement technology, applied in the field of bioengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

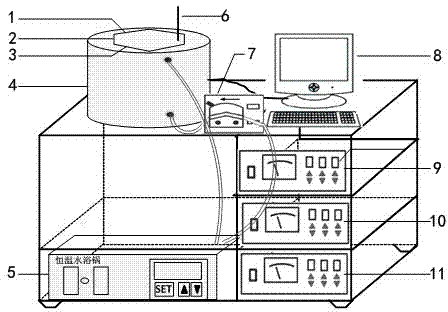

Image

Examples

Embodiment 1

[0023] Example 1. Prepare 6 L of 2% gluten protein suspension, under the condition of mechanical stirring, the frequency is 20 kHz, 28 kHz, 35 kHz, the three-frequency ultrasonic time is 20s, 20s, 20s; the ultrasonic power is 16.67 W / L, Divergent ultrasonic treatment at an initial temperature of 30°C for 30 min; adding alkaline protease at a rate of 3800 U / g for enzymolysis at a temperature of 50°C and a pH of 9.0 for 30 min; after enzymolysis, the The enzymolysis solution was boiled for 10 minutes to inactivate the enzyme, centrifuged at 12000 r / min for 10 minutes, and the supernatant was collected to obtain the extract of the protein blood pressure lowering peptide. The gluten protein hypotensive peptide extract was diluted 2 times to determine the ACE inhibitory activity.

[0024]After measurement, the ACE inhibition rate of the dilute enzymatic hydrolyzate with ultrasonic treatment was 73.80%, and compared with the control (1), the blood pressure lowering activity was i...

Embodiment 2

[0025] Example 2. Prepare 6 L of 3% gluten protein suspension, under the condition of mechanical stirring, the frequency is 20kHz, 28kHz, 35kHz, the three-frequency ultrasonic time is 20s, 20s, 20s; the ultrasonic power is 16.67 W / L, and the initial temperature is Divergent ultrasonic treatment at 20°C for 30 min; add alkaline protease at a rate of 3800 U / g for enzymolysis, the temperature of enzymolysis is 50°C, pH is 9.0, and enzymolysis is 30 minutes; after enzymolysis, the enzymolysis The solution was boiled for 10 min to inactivate the enzyme, centrifuged at 12000 r / min for 10 min, and the supernatant was collected to obtain the extract of the protein blood pressure lowering peptide. The gluten protein hypotensive peptide extract was diluted 3 times to determine the ACE inhibitory activity.

[0026] After measurement, the ACE inhibition rate of the dilute solution of the enzymatic hydrolyzate treated with ultrasonic treatment was 77.73%, and the blood pressure lowering...

Embodiment 3

[0027] Example 3. Prepare 6 L of 3% gluten protein suspension, under the condition of mechanical stirring, the frequency is 20 kHz, 28 kHz, 35 kHz, the single-frequency ultrasonic time is 20s, 20s, 20s; the ultrasonic power is 16.67 W / L, The initial temperature was 20°C and diffuse ultrasonic treatment for 50 minutes; alkaline protease was added at a ratio of 3800 U / g for enzymolysis, the temperature of enzymolysis was 50°C, pH was 9.0, and the enzymolysis was 30 minutes; after the end of enzymolysis, The enzymolysis solution was boiled for 10 minutes to inactivate the enzyme, centrifuged at 12000 r / min for 10 minutes, and the supernatant was collected to obtain the extract of the protein blood pressure lowering peptide. The gluten protein hypotensive peptide extract was diluted 3 times to determine the ACE inhibitory activity.

[0028] After measurement, the ACE inhibition rate of the dilute solution of the enzymatic hydrolyzate treated with ultrasonic treatment was 76.76%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com