Method for preparing hydrophilic lubrication coating layer on surface of inert high-molecular material and medical instrument

A polymer material and lubricating coating technology, which is applied in the surface treatment of medical inert polymer materials and inert polymer material surface treatment fields, to achieve the effect of firm combination, improved hydrophilic lubricity and mechanical stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

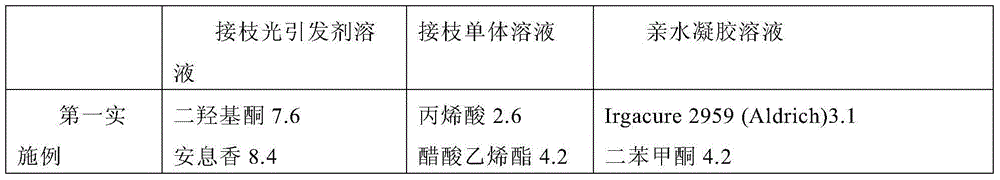

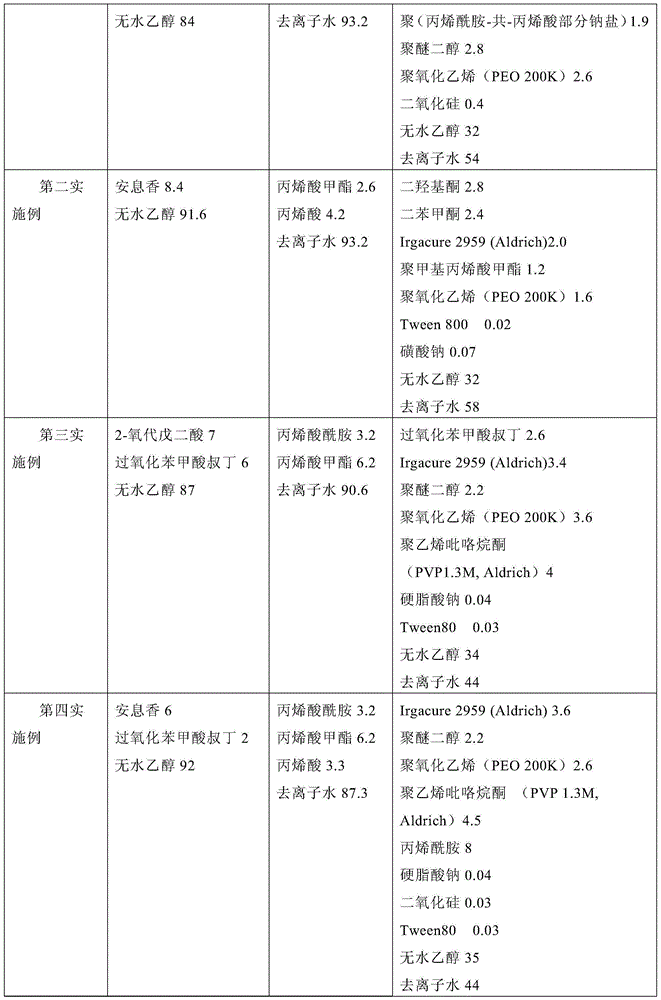

Examples

Embodiment Construction

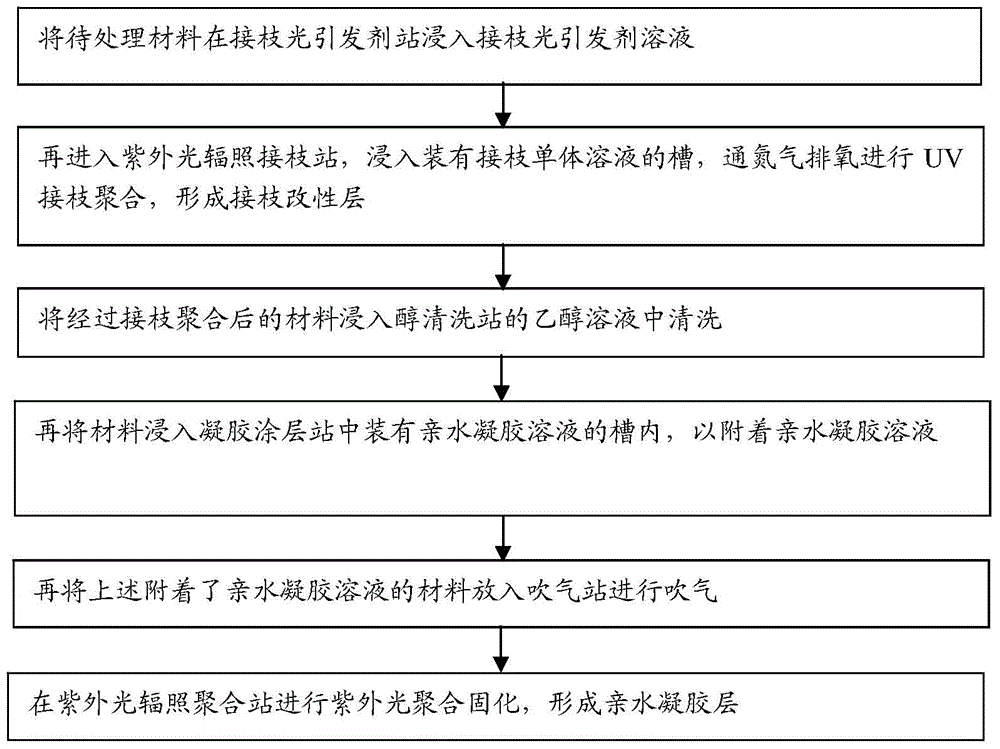

[0037] A method for preparing a hydrophilic lubricating coating on the surface of an inert polymer material according to an embodiment of the present invention comprises the following steps:

[0038] Immersing the inert polymer material in the grafted photoinitiator solution for 1-10 minutes;

[0039] Immerse the inert polymer material dipped in the grafted photoinitiator into the grafted monomer solution for 5-20 minutes, carry out ultraviolet light irradiation modification and graft polymerization, and form a graft modified layer on the surface of the inert polymer material ;

[0040] Clean the inert polymer material after graft polymerization;

[0041] Immerse the cleaned inert polymer material in the hydrophilic gel solution for 1-10 minutes;

[0042] The hydrophilic gel solution attached to the surface of the inert polymer material is polymerized and cured by ultraviolet light (ie UV), and a hydrophilic gel layer is formed on the surface of the graft modified layer.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com