Preparation method of tara gum edible membrane with hydrophobic performance

A technology of tara gum and performance is applied in the field of preparation of edible film materials, which can solve problems such as poor hydrophobicity of edible film, and achieve the effect of improving hydrophobic performance, good mechanical performance and good thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

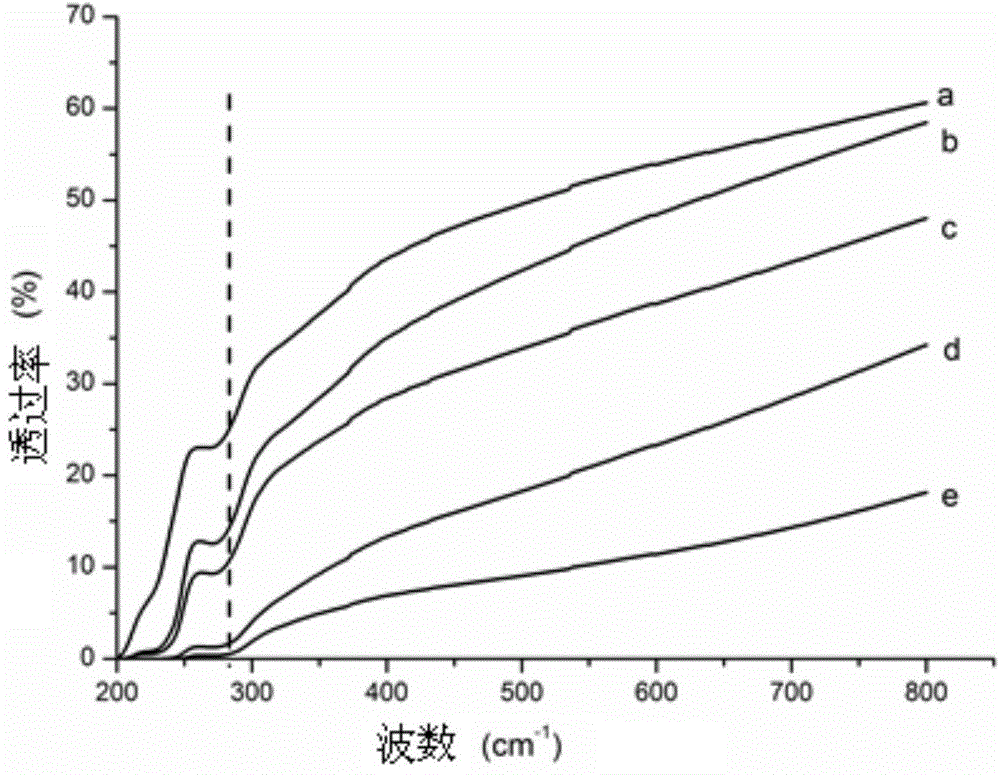

Image

Examples

specific Embodiment approach 1

[0024] Embodiment one: a kind of preparation method of the tara gum edible film with hydrophobic property of the present embodiment, carries out according to the following steps:

[0025] 1. After pulverizing tara gum, add tara gum into water according to the mass percentage concentration of tara gum at 0.5-2%, heat to 40-50°C, stir for 2-5 hours, and then centrifuge to remove insoluble impurities to obtain tower gum Glue solution;

[0026] Two, take by weighing the mixed solution of glycerin and sorbitol by 10%~20% of tara gum quality in the tara gum solution, wherein the mass ratio of glycerin and sorbitol in the mixed solution of glycerol and sorbitol is 1:(1~ 1.2), weigh oleic acid according to 1% to 20% of the quality of tara gum in the tara gum solution, first add the mixed solution of glycerin and sorbitol into the tara gum solution, stir evenly, then add oleic acid, stir After uniformity, add it to a homogenizer, and homogenize it for 2 to 5 minutes at a speed of 7000...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass percent concentration of tara gum in step one is 1%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the heating temperature in step 1 is 45° C., and the stirring time is 3 hours. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

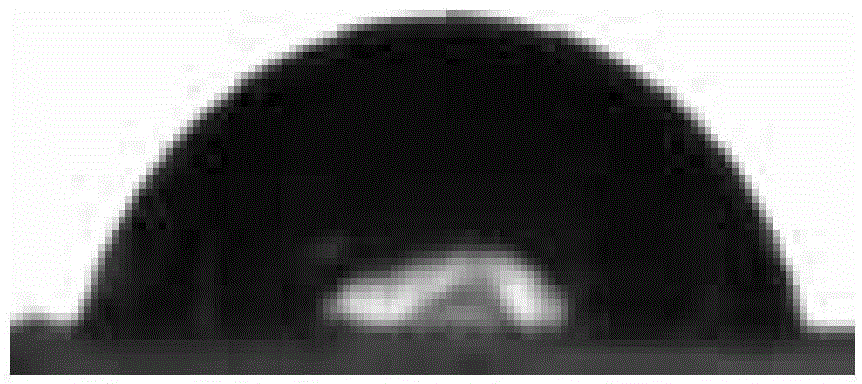

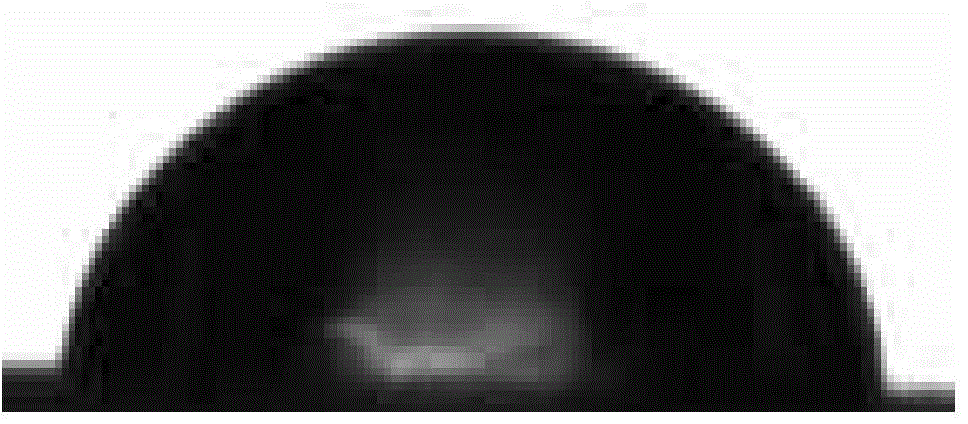

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com