Method for bonding carbon fiber/phenolic-nitrile rubber materials

A technology of nitrile rubber and carbon fiber, which is applied in the direction of surface pretreatment bonding method, adhesive heating bonding method, bonding method, etc., and can solve interlayer air trapping, debonding, and different material properties, etc. problem, achieve the effect of improving bonding strength, eliminating thermal stress, and avoiding interface debonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

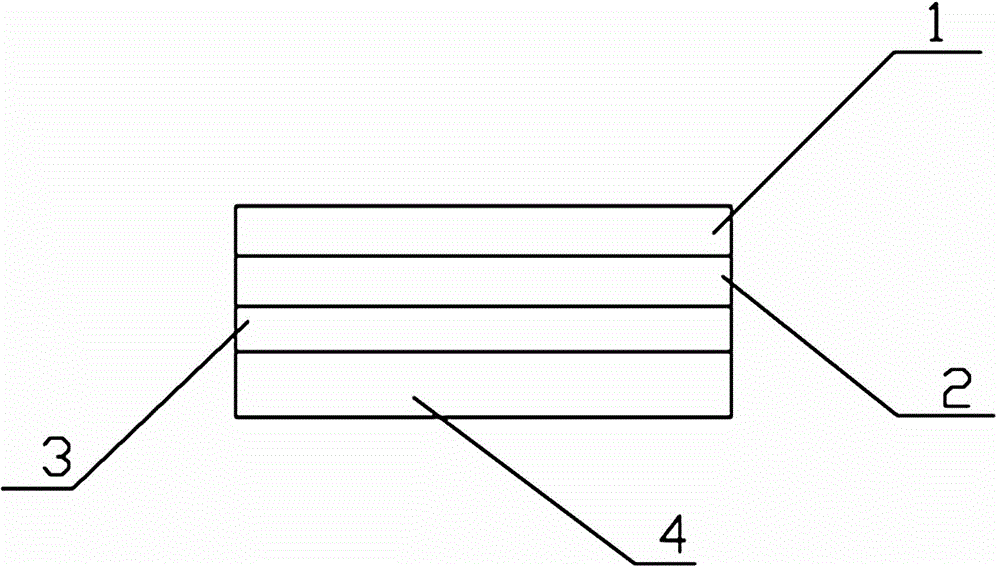

Image

Examples

Embodiment 1

[0031] For a solid rocket motor, EPDM insulation material (bottom layer) is 3mm thick, carbon fiber / phenolic-nitrile rubber material is 6mm thick, and EPDM insulation material (surface layer) is 4mm thick;

[0032] 1) Preparatory steps: According to the structural size requirements of the engine heat insulation layer, the EPDM heat insulation material is rolled and formed, and the carbon fiber / phenolic-nitrile rubber material is cut into shape;

[0033] 2) Brushing steps: clean the carbon fiber / phenolic-nitrile rubber material with chemically pure ethyl acetate, and let it dry for 1 hour; brush CH238 glue, the thickness of the adhesive film is controlled at 5 μm, and let it stand for 1 hour; EPDM material The thermal insulation material (bottom layer) is cleaned with chemically pure ethyl acetate, and left to air for 1 hour; brush CH238 glue, and the thickness of the adhesive film is controlled at 5 μm, and aired for 1 hour;

[0034] 3) Prefabrication steps: paste the carbon f...

Embodiment 2

[0049] For a solid rocket motor, EPDM insulation material (bottom layer) is 2mm thick, carbon fiber / phenolic-nitrile rubber material is 4mm thick, and EPDM insulation material (surface layer) is 4mm thick;

[0050] 1) Preparatory steps: According to the structural size requirements of the engine heat insulation layer, the EPDM heat insulation material is rolled and formed, and the carbon fiber / phenolic-nitrile rubber material is cut into shape;

[0051] 2) Brushing steps: clean the carbon fiber / phenolic-nitrile rubber material with chemically pure ethyl acetate, and let it dry for 1 hour; brush CH238 glue, the thickness of the adhesive film is controlled at 10 μm, and let it stand for 2 hours; EPDM material The thermal insulation material (bottom layer) is cleaned with chemically pure ethyl acetate, and left to air for 1 hour; brush CH238 glue, the thickness of the adhesive film is controlled at 10 μm, and aired for 2 hours;

[0052] 3) Prefabrication step: Paste the carbon fi...

Embodiment 3

[0067] For a solid rocket motor, EPDM insulation material (bottom layer) is 3mm thick, carbon fiber / phenolic-nitrile rubber material is 2mm thick, and EPDM insulation material (surface layer) is 4mm thick;

[0068] 1) Preparatory steps: According to the structural size requirements of the engine heat insulation layer, the EPDM heat insulation material is rolled and formed, and the carbon fiber / phenolic-nitrile rubber material is cut into shape;

[0069] 2) Brushing steps: clean the carbon fiber / phenolic-nitrile rubber material with chemically pure ethyl acetate, and let it dry for 1 hour; brush CH238 glue, the thickness of the adhesive film is controlled at 10 μm, and let it stand for 2 hours; EPDM material The thermal insulation material (bottom layer) is cleaned with chemically pure ethyl acetate, and left to air for 1 hour; brush CH238 glue, the thickness of the adhesive film is controlled at 10 μm, and aired for 2 hours;

[0070] 3) Prefabrication step: Paste the carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com