Low-temperature-resistant fracturing fluid for oil exploitation and preparation method of fracturing fluid

A technology for oil exploitation and low temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as difficult fracturing, poor low temperature resistance of fracturing fluid, and rapid decrease in sand-carrying capacity of fracturing fluid, etc. , to achieve excellent low temperature resistance, good shear resistance, and suitable for large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

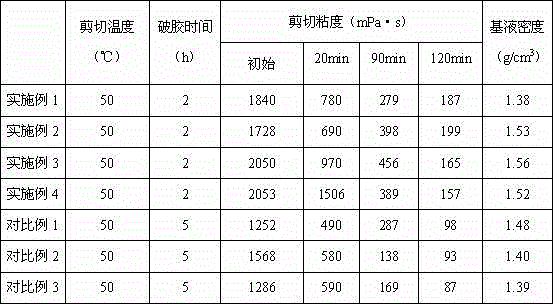

Examples

Embodiment 1

[0025] The low-temperature resistant fracturing fluid used for petroleum development includes the following components in parts by weight: 0.5 parts of cellulase, 2 parts of acrylamide, 1 part of triethanolamine sulfosalicylate, 1.5 parts of coumarin, guar 0.2 parts of glue, 0.6 parts of bactericide, 0.2 parts of polyacrylamide, 2 parts of sodium bicarbonate, 1 part of sodium citrate, 1 part of polyoxypropylene polyoxyethylene propylene glycol ether, 2 parts of ethanol, and 150 parts of water, wherein the sterilization The agent is rosinamine.

[0026] The preparation method of low-temperature-resistant fracturing fluid used for petroleum exploitation comprises the steps of:

[0027] Step 1: Mix and stir cellulase, acrylamide and triethanolamine sulfosalicylate evenly, raise the temperature to 40°C, then add coumarin and guar gum in sequence, and stir evenly to obtain mixture A;

[0028] Step 2, mixing and stirring the fungicide, polyacrylamide, sodium bicarbonate, sodium cit...

Embodiment 2

[0032] Low-temperature resistant fracturing fluid for petroleum development, including the following components in parts by weight: 2 parts of cellulase, 8 parts of acrylamide, 5 parts of triethanolamine sulfosalicylate, 2 parts of coumarin, guar 1.8 parts of glue, 2.5 parts of bactericide, 0.8 parts of polyacrylamide, 5 parts of sodium bicarbonate, 3 parts of sodium citrate, 5 parts of polyoxypropylene polyoxyethylene propylene glycol ether, 10 parts of ethanol, and 180 parts of water, wherein the sterilization The agent is rosinamine.

[0033] The preparation method of low-temperature-resistant fracturing fluid used for petroleum exploitation comprises the steps of:

[0034] Step 1: Mix and stir cellulase, acrylamide and triethanolamine sulfosalicylate evenly, raise the temperature to 50°C, then add coumarin and guar gum in sequence, and stir evenly to obtain mixture A;

[0035] Step 2, mixing and stirring the fungicide, polyacrylamide, sodium bicarbonate, sodium citrate, p...

Embodiment 3

[0039] The low-temperature resistant fracturing fluid used for petroleum development includes the following components in parts by weight: 1 part of cellulase, 5 parts of acrylamide, 2 parts of triethanolamine sulfosalicylate, 1.6 parts of coumarin, guar 1 part of glue, 1.8 parts of fungicide, 0.5 part of polyacrylamide, 3 parts of sodium bicarbonate, 2 parts of sodium citrate, 3 parts of polyoxypropylene polyoxyethylene propylene glycol ether, 5 parts of ethanol, and 170 parts of water, wherein the sterilization The agent is rosinamine.

[0040] The preparation method of low-temperature-resistant fracturing fluid used for petroleum exploitation comprises the steps of:

[0041] Step 1: Mix and stir cellulase, acrylamide and triethanolamine sulfosalicylate evenly, raise the temperature to 45°C, then add coumarin and guar gum in sequence, and stir evenly to obtain mixture A;

[0042] Step 2, mixing and stirring the fungicide, polyacrylamide, sodium bicarbonate, sodium citrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com