Threaded sealing grease with characteristics of rust resistance, wipe resistance and environmental protection, and preparation process thereof

A thread sealing and preparation process technology, applied in the field of thread grease, can solve problems such as environmental and human hazards, corrosion resistance and friction resistance, and reduce health damage, improve abrasion resistance and corrosion resistance, and reduce environmental protection. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

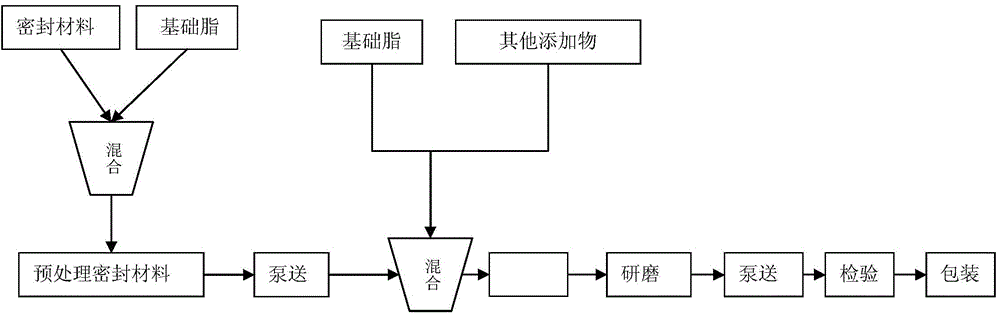

Method used

Image

Examples

Embodiment 1

[0021] Add base grease accounting for 20% of the weight of the sealing grease composition, 10% of expanded graphite powder, stir in the mixer for 20 minutes, colloidally grind and filter; pump the sealing material into the mixer, and add 22.5% of the weight of the sealing grease composition. Graphite powder, 7.5% light calcium carbonate anti-wear material and 20% base grease, finally add 20% copper powder, stir for 60 minutes, grind, pump, filter, inspect, and pack to get the product.

Embodiment 2

[0023] Add base grease accounting for 25% of the weight of the sealing grease composition, 20% expanded graphite powder, stir in the mixer for 30 minutes, colloidally grind and filter; pump into the mixer, add 15% of the weight of the sealing grease composition flake graphite powder, 5% light calcium carbonate anti-wear material and 25% base grease, finally add 10% copper powder, stir for 40 minutes, grind, pump, filter, inspect, and pack to get the product.

Embodiment 3

[0025] Add base grease accounting for 22.5% of the weight of the sealing grease composition, 15% expanded graphite powder, stir in the mixer for 25 minutes, colloidally grind and filter; pump into the mixer, add 19% of the weight of the sealing grease composition flake graphite powder, 6% light calcium carbonate anti-wear material and 22.5% base grease, finally add 15% copper powder, stir for 50 minutes, grind, pump, filter, inspect, and pack to get the product.

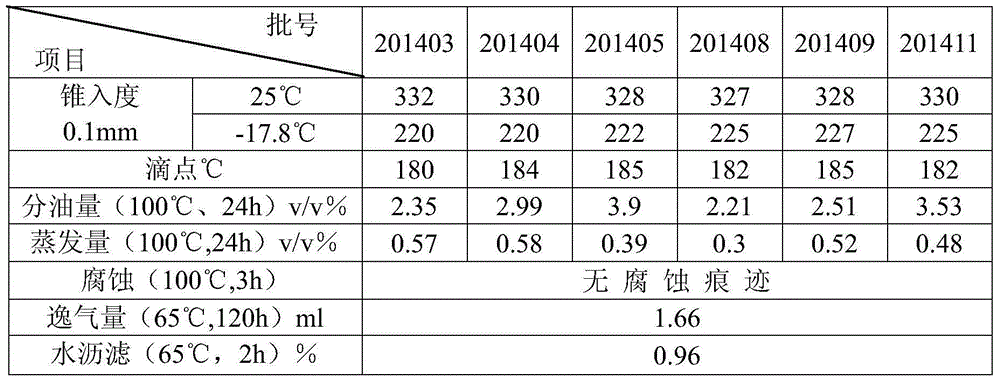

[0026] After testing, the product has been inspected by the National Petroleum Pipe Quality Supervision and Inspection Center. All indicators meet the requirements of API RP5A3 standards and the quality is stable. All indicators have reached the leading level of similar products at home and abroad. The test results of batches of products are shown in the table below:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com