Method for preparing 1, 3-dilinolein-2-palmitic acid triglyceride

A technology of palmitic acid triglyceride and dioleic acid, applied in the field of oils and fats, can solve the problems of complex process, difficult industrialized production and the like, and achieve the effects of wide sources, small proportion and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

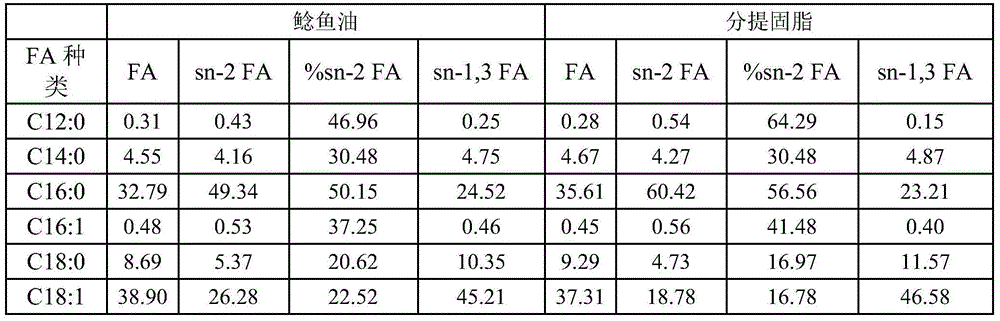

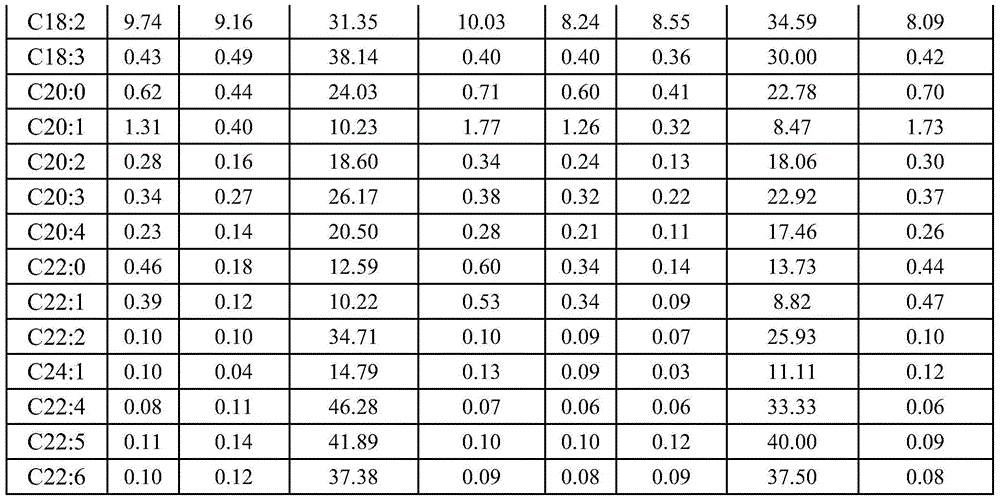

[0022] The refined freshwater catfish oil was melted at 60°C and kept for 30 minutes, then the catfish oil was cooled to 30°C at a cooling rate of 5°C / min, and crystallized for 8 hours, and the solid fat in the catfish oil was separated. The catfish oil is vacuum filtered to obtain the solid fat component. Fractionated solid fat contains higher sn-2 palmitic acid and total palmitic acid than catfish oil. The fatty acid composition and distribution of the used catfish oil and its fractionated solid fat are shown in the following table:

[0023] Table 1. Fatty acid composition and distribution of catfish oil and its fractionated solid fat

[0024]

[0025]

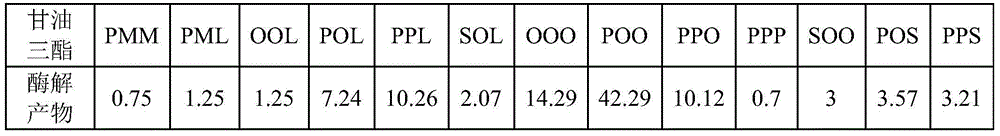

[0026] Catfish solid lipid components were acid-hydrolyzed in a batch reactor, using 1,3-specific lipase Lipozyme RMIM as a catalyst, using fatty acids derived from high oleic sunflower oil as acyl donors, and the molar ratio of catfish oil to fatty acids was 1:6, the reaction temperature is 50°C, the amount of enzym...

example 2

[0034] Melt the refined freshwater catfish oil at 50°C and keep it for 60 minutes, then lower the temperature of the catfish oil to 20°C at a cooling rate of 3°C / min, crystallize for 7 hours, and analyze the solid fat in the catfish oil. The catfish oil is vacuum filtered to obtain solid fat components. Fractionated solid fat contains higher sn-2 palmitic acid and total palmitic acid than catfish oil. The fatty acid composition and distribution of gained catfish oil fractionation solid fat are shown in table 4 below:

[0035] Table 4. Fatty acid composition and distribution of catfish oil fractionated and solidified at 20℃

[0036]

[0037] Acid hydrolysis of catfish solid lipid components in a packed bed continuous reactor, using 1,3-specific lipase Lipozyme TL IM as a catalyst, using fatty acids derived from high oleic rapeseed oil as acyl donors, catfish oil and fatty acids The molar ratio was 1:5, the reaction temperature was 40 °C, and the substrate residence time wa...

example 3

[0046]Refined freshwater catfish oil was melted at 55°C and kept for 50 minutes, then the catfish oil was cooled to 25°C at a cooling rate of 2°C / min, and crystallized for 10 hours, and the solid fat components in the catfish oil were separated. The catfish oil is vacuum filtered to obtain the solid fat component. Fractionated solid fat contains higher sn-2 palmitic acid and total palmitic acid than catfish oil. The fatty acid composition and distribution of gained catfish oil fractionation solid fat are as shown in table 7 below:

[0047] Table 7. Fatty acid composition and distribution of catfish oil fractionated and solidified at 25℃

[0048] FA type

FA

sn-2FA

%sn-2FA

sn-1,3FA

C12:0

0.33

0.59

59.60

0.20

C14:0

4.72

4.38

30.93

4.89

C16:0

34.88

58.89

56.28

22.88

C16:1

0.49

0.62

42.18

0.43

C18:0

9.22

4.88

17.64

11.39

C18:1

37.57...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com