Low-grade iron ore direct reduction method

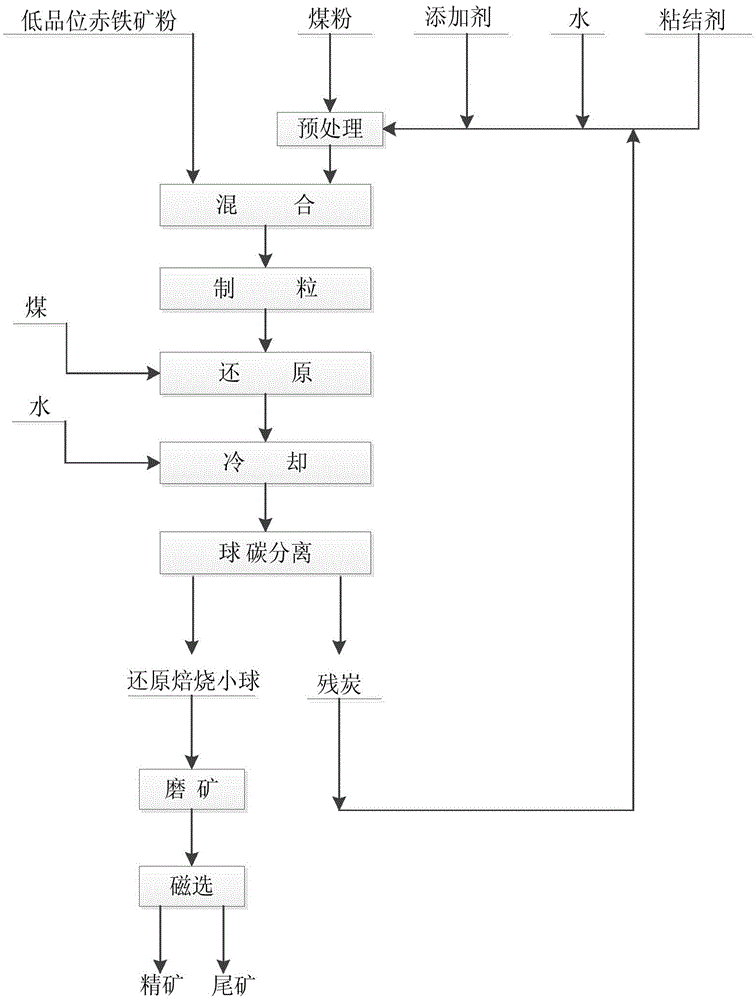

A low-grade iron ore, direct technology, applied in the field of direct reduction of low-grade iron ore, can solve the problems of high reduction temperature, low-grade iron ore difficult to effectively use, easy ring formation cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The mass percentages of low-grade iron ore and coal less than 0.074mm after crushing and grinding are 80.45% and 47.38% respectively, and the coal particles are prepared according to the C / Fe mass ratio of 0.3; Take NaCl, mix bentonite according to 1.5% of the total mass of iron ore dry basis, and mix water according to 6.0% of the total mass of iron ore dry basis; The wet and additives penetrate into the pores and cracks of the coal particles under the action of water to obtain the pretreated internal blended coal; then the internal blended coal and iron ore particles are mixed evenly, and the discs are granulated into small pellets with a diameter of 3 to 8 mm. Balls (wherein the mass percentage of water is 11.50%); after the granulated ball wet ball enters the kiln, the heating time for the furnace charge temperature to rise from room temperature to 950°C in the rotary tube furnace is 60min, and the coal-based process is carried out at 950°C Direct reduction and roas...

Embodiment 2

[0064]The mass percentages of low-grade iron ore and coal less than 0.074mm after crushing and grinding are 80.45% and 47.38% respectively, and the coal particles are prepared according to the C / Fe mass ratio of 0.2; Take NaCl, mix bentonite according to 1.5% of the total mass of iron ore dry basis, and mix water according to 6.0% of the total mass of iron ore dry basis; then mix coal particles, NaCl, bentonite, and water until the coal powder particles are fully moistened Wet and additives penetrate into the pores and cracks of coal particles under the action of water to obtain pretreated internal blended coal; then the internal blended coal and iron ore particles are mixed evenly, and disc granulated into small granulated particles with a diameter of 3 to 8 mm. ball (wherein the mass percentage of water is 11.58%); after the granulation ball wet ball enters the kiln, the heating time for the temperature of the charge in the rotary tube furnace is raised from normal temperatur...

Embodiment 3

[0066] The mass percentages of low-grade iron ore and coal less than 0.074mm after crushing and grinding are 80.45% and 47.38% respectively, and the coal particles are prepared according to the C / Fe mass ratio of 0.4; Take NaCl, mix bentonite according to 1.5% of the total mass of iron ore dry basis, and mix water according to 6.0% of the total mass of iron ore dry basis; then mix coal particles, NaCl, bentonite, and water until the coal powder particles are fully moistened Wet and additives penetrate into the pores and cracks of coal particles under the action of water to obtain pretreated internal blended coal; then the internal blended coal and iron ore particles are mixed evenly, and disc granulated into small granulated particles with a diameter of 3 to 8 mm. ball (wherein the mass percentage of water is 11.48%); after the granulation ball wet ball enters the kiln, the heating time of the temperature of the charge in the rotary tube furnace is raised from room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com