A method for shortening the roasting time of pellets

A roasting and pelletizing technology, which is applied in the field of iron and steel metallurgy, can solve the problems of affecting pellet quality and performance indicators, low oxidation degree of roasting pellets, and long roasting time of pellets, so as to shorten roasting time, increase oxygen potential, The effect of increasing the degree of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

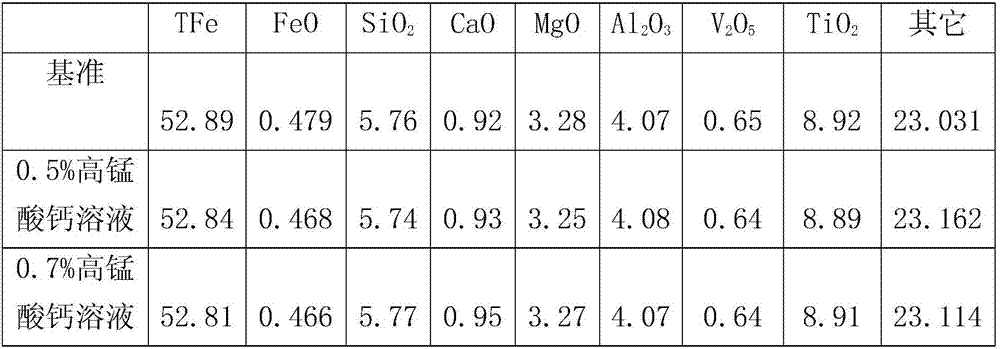

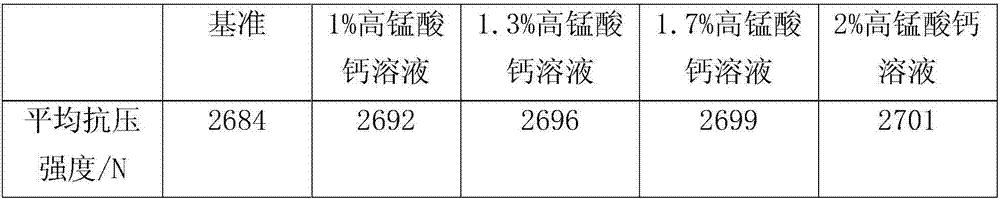

[0016] Embodiment: A method for shortening the roasting time of pellets, adding bentonite and mineral powder with a total weight of 10kg into a mixer, mixing it for 5 minutes with a mixer, and adding half of the mixed material into a pellet at one time In the disc pelletizing machine, turn on the disc pelletizing machine and start adding calcium permanganate solution. After the cue ball of the mixture in the pelletizing machine appears, gradually add the remaining mixture into the pelletizing machine, and wait for the raw pellets to form After finishing, take out the raw balls and put them in the corundum crucible, put them into the preheating furnace, and after preheating for 45 minutes, move the balls into the pellet roasting furnace for roasting. After roasting, take out the balls and place them in the air to cool. After the pellets have cooled completely, measure the strength of the pellets.

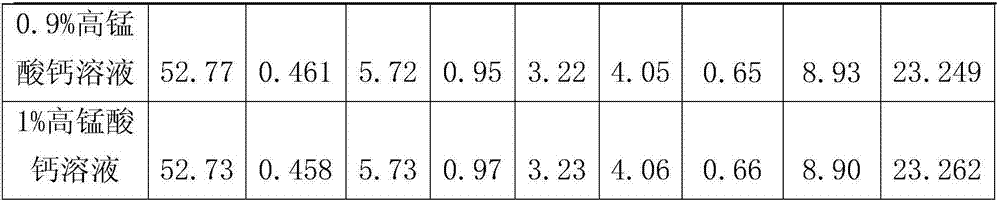

[0017] Prepare 1%, 1.3%, 1.7% and 2% calcium permanganate solutions respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com