Ship tail gas integrated purification device and its application

A purification device and a technology for ship exhaust gas, which is applied in the directions of gas treatment, air quality improvement, chemical instruments and methods, etc., and can solve problems such as the application of supergravity devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Such as Figure 8 As shown, in the process of marine fuel oil exhaust, the device with the first structure is used to remove SO in the exhaust 2 , NO and PMs, the mesh rotor combination is sparse-sparse-sparse, remove the foam screen, the mesh rotor mesh combination is 28-30-30, and no spin spoiler is placed. The liquid phase oxidant is sodium chlorite, the pH is adjusted to be 8, the absorbent is urea, and the mass fraction is 10wt%; the gas volume is 60m 3 / h, the liquid volume is 200L / h, the speed is 1000-2000r / min; the SO in the imported gas 2 The content of NO is 1200ppm, the content of NO is 1000ppm, and the content of PMs is 500 mg / m 3 ; The reaction temperature is normal temperature.

[0060] After testing, the method of the present invention, SO 2 The absorption efficiency is about 88%, the NO absorption efficiency is about 57%, the PMs absorption efficiency is about 85%, and mist is detected at the outlet. The invention has better desulfurization, denitri...

Embodiment 2

[0062] Such as Figure 8 As shown, in the process of marine fuel oil exhaust, the device with the first structure is used to remove SO in the exhaust 2 , NO and PMs, the combination of the screen rotor is sparse-sparse-sparse, and the demister screen is placed, and the combination of the demister screen is pro-pro-pro, and the mesh number combination of the screen rotor and the demister screen is 28 -30-30 without placing spin spoilers. The liquid phase oxidant is sodium chlorite, the pH is adjusted to be 8, the absorbent is urea, and the mass fraction is 10wt%; the gas volume is 60m 3 / h, the liquid volume is 200L / h, the speed is 1000-2000r / min; the SO in the imported gas 2 The content of NO is 1200 ppm, the content of NO is 1000 ppm, and the content of PMs is 500 mg / m 3 ; The reaction temperature is normal temperature.

[0063] After testing, the method of the present invention, SO 2 The absorption efficiency is about 90%, the NO absorption efficiency is about 60%, the ...

Embodiment 3

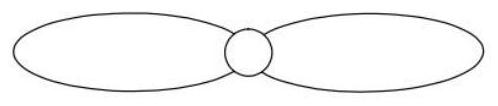

[0065] Such as Figure 8 As shown, in the process of ship fuel oil exhaust, the device with the first structure is used to remove SO in the exhaust2 , NO and PMs, the combination of the screen rotor is sparse-sparse-sparse, and the demister screen is placed, and the combination of the demister screen is pro-pro-pro, and the mesh number combination of the screen rotor and the demister screen is 28 -30-30, placed figure 2 The spin spoiler shown. The liquid phase oxidant is sodium chlorite, the pH is adjusted to be 8, the absorbent is urea, and the mass fraction is 10wt%; the gas volume is 60m 3 / h, the liquid volume is 200L / h, the speed is 1000-2000r / min; the SO in the imported gas 2 The content of NO is 1000-1200ppm, the content of NO is 500-1000ppm, and the content of PMs is 500mg / m 3 ; The reaction temperature is normal temperature.

[0066] After testing, the method of the present invention, SO 2 The absorption efficiency is about 93%, the NO absorption efficiency is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com