System device and method for deeply removing nitric oxide in industrial tail gas

A technology for nitrogen oxides and industrial tail gas, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of small equipment size, high operating cost, poor mass transfer effect, etc. Denitrification effect, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

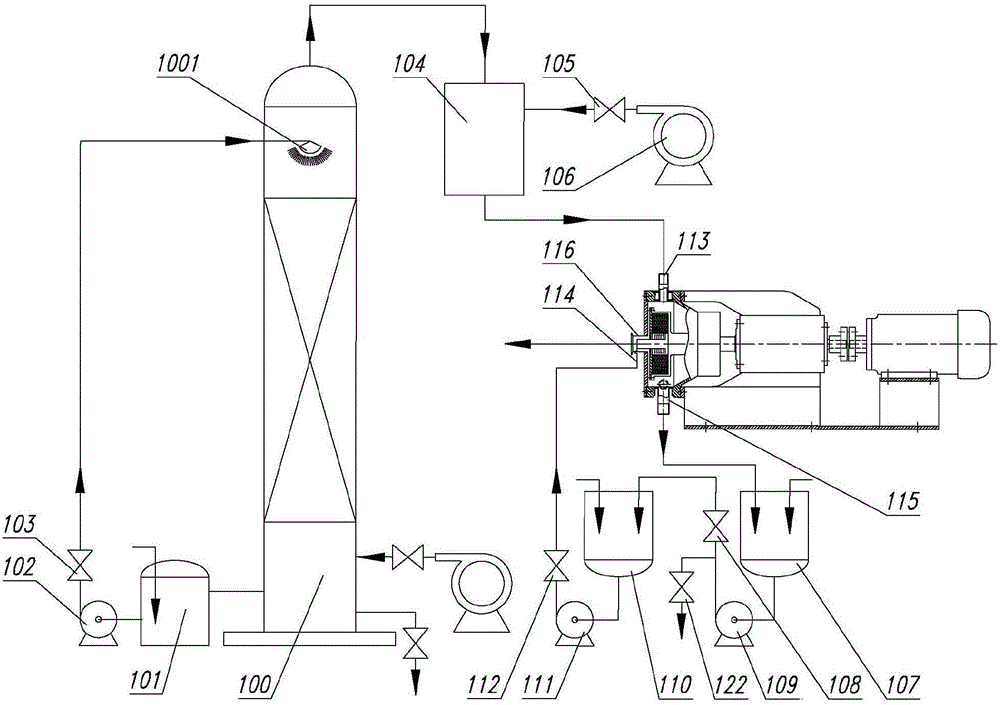

[0042] see figure 1 As shown, a system device for deep removal of nitrogen oxides in industrial tail gas includes an absorption tower 100, a first absorption liquid storage tank 101, a first delivery pump 102, a first regulating valve 103, a gas distribution tank 104, and a gas distribution tank 104. Valve 105, air distribution fan 106, supergravity rotating bed, liquid recovery tank 107, third delivery pump 109, third regulating valve 108, second absorption liquid storage tank 110, second delivery pump 111 and second regulating valve 112; The lower part of the absorption tower 100 is connected to the first absorption liquid storage tank 101 through a pipeline, and the first absorption liquid storage tank 101 is connected to the upper part of the absorption tower 100 through the first delivery pump 102 and the first regulating valve 103 in sequence. The spray head 1001 is connected and communicated; the gas outlet of the absorption tower 100 is connected and communicated with ...

Embodiment 2

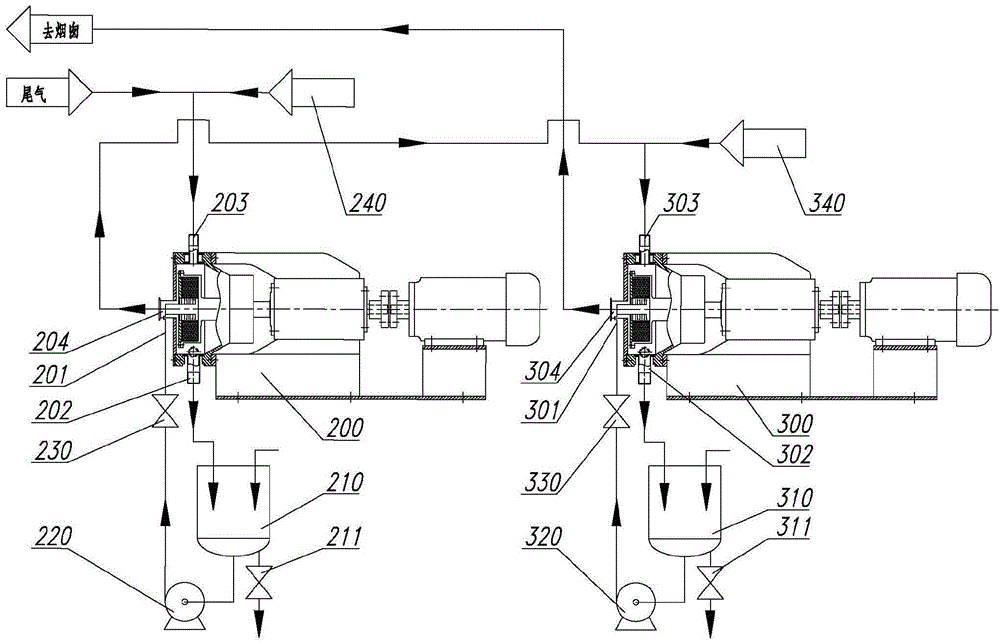

[0045] see figure 2 As shown, a system device for deep removal of nitrogen oxides in industrial tail gas includes a first-stage high-gravity rotating bed 200, a first absorption liquid storage tank 210, a first delivery pump 220, a first liquid inlet regulating valve 230, The first gas distribution device 240, the second stage high-gravity rotating bed 300, the second absorption liquid storage tank 310, the second delivery pump 320, the second liquid inlet regulating valve 330 and the second gas distribution device 340; the first stage The liquid outlet 202 of the high-gravity rotating bed 200 is connected to the first absorption liquid storage tank 210 through a pipeline, and the first absorption liquid storage tank 210 is connected to the first stage through the first delivery pump 220 and the first liquid inlet regulating valve 230 in sequence. The liquid inlet 201 of the high-gravity rotating bed 200 is connected and connected, and the first gas distribution device 240 is...

Embodiment 3

[0049] Utilize the system device of above-mentioned embodiment 1 to carry out the method for deep removal of nitrogen oxides in industrial tail gas, comprise the steps:

[0050] 1) Input the industrial tail gas containing nitrogen oxides into the bottom of the absorption tower 100;

[0051] 2) The spray head 1001 at the top of the absorption tower 100 sprays out the absorption liquid to absorb the nitrogen oxides in the tail gas, and the gas absorbed by the absorption liquid is discharged from the top of the absorption tower into the gas distribution tank 104, and the oxidizing gas in the gas distribution tank 104 After the gas undergoes an oxidation reaction, it enters the supergravity rotating bed from the gas inlet 113 for deep removal of nitrogen oxides; the absorption liquid in the absorption tower after spraying enters the first absorption liquid storage tank 101, and then passes through the first conveying The pump 102 and the first regulating valve 103 are sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com