Optical fiber end head pressing device with simple structure

A technology with simple structure and optical fiber, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of inconvenient small-scale processing and use, complex structure, etc., and achieve the effect of simple and practical principle, easy operation, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

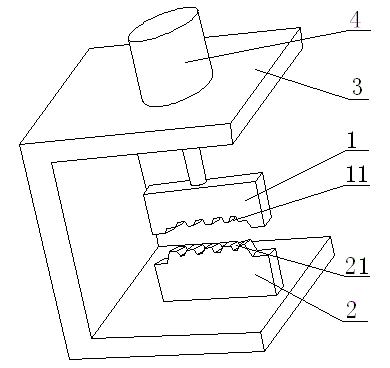

[0018] like figure 1 The illustrated optical fiber end pressing device with simple structure includes an operating table 3, a lower pressure-bearing block 2 fixed on the operating table 3, and an upper pressing block 1 located above the lower pressure-bearing block. The operating table 3 A lifting control device 4 for controlling the up and down movement of the upper pressing block 1 is arranged on the top, the lower pressure bearing block 2 is provided with an optical fiber placement groove 21, and the upper pressing block 1 is provided with an optical fiber placement groove 21 corresponding to the optical fiber The pressing groove 11, when the optical fiber pressing groove 11 is pressed on the optical fiber placement groove 21, both of them form a regular hexagonal pressing groove.

[0019] During operation, the connecting ring is sleeved on the connection between the optical fiber and the connector, the connecting ring is placed in the optical fiber placement groove 21, and...

Embodiment 2

[0021] like figure 1 The optical fiber end pressing device with a simple structure is shown. In order to facilitate the operation of the lifting control device, this embodiment is optimized on the basis of the above-mentioned embodiment, that is, the lifting control device 4 is a hydraulic cylinder or a pneumatic cylinder. cylinder.

[0022] The upper pressing block 1 is fixed on the piston rod of the lifting control device 4 .

Embodiment 3

[0024] like figure 1 In the illustrated optical fiber end pressing device with a simple structure, in order to improve the pressing efficiency of the optical fiber end, this embodiment is optimized on the basis of the above-mentioned embodiment, that is, the lower pressure bearing block 2 is provided with multiple A fiber placement groove 21.

[0025] In order to facilitate the manufacture of the optical fiber placement groove and the optical fiber pressing groove, the cross section of the optical fiber placement groove 21 is an isosceles trapezoid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com