Method for preparing continuous surface-shape spiral phase plate

A technology of spiral phase plate and surface shape, which can be applied in opto-mechanical equipment, photo-engraving process of patterned surface, and originals for opto-mechanical processing, etc. It can solve the problems of low production efficiency, high production cost and many production processes. , to achieve the effect of high preparation efficiency, strong versatility and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But the following examples are limited to explain the present invention, and the protection scope of the present invention should include the entire content of the claims, and through the following examples, those skilled in the art can realize the entire contents of the claims of the present invention.

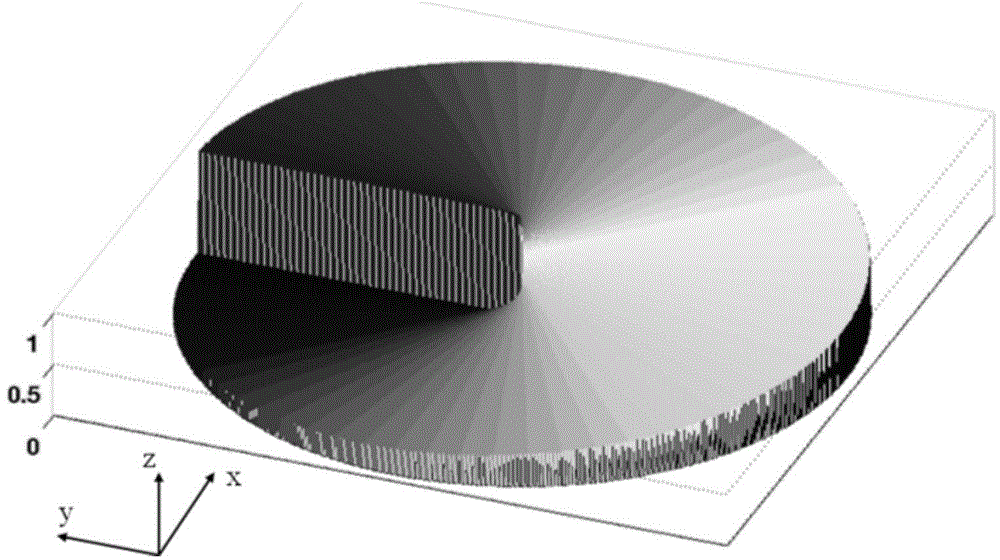

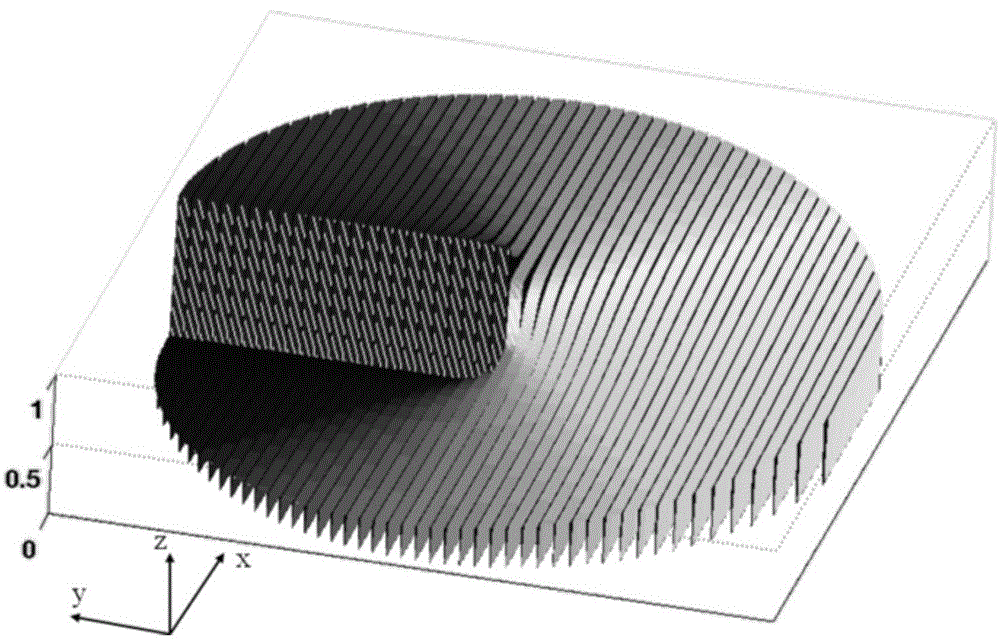

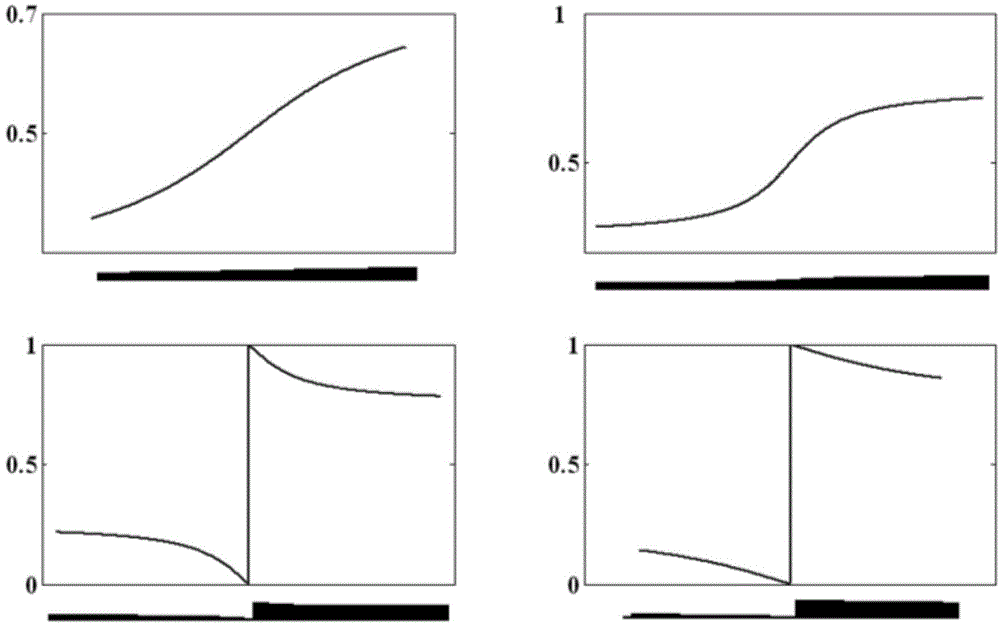

[0020] A method for preparing a continuous surface spiral phase plate in a specific embodiment is shown in the figure. figure 1 is the surface shape of the target structure to be prepared, it can be seen that the spiral phase plate is a structure whose sagittal height changes with the angle, its aperture D is 1 inch, the wavelength used is 532nm, and the corresponding phase modulation range is 0-2π, that is The corresponding saggy height h is 1.154 μm. Then it can be calculated At the same time, 10×h=11.54 μm. According to the selection cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com