Distributed digital point inspection method and distributed digital point inspection system for sewing machine

A point inspection system and sewing machine technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as waste of human resources, unfavorable environmental protection, and unfavorable production line management, so as to reduce failure and accident shutdown rate and facilitate production line management , the effect of effective storage and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

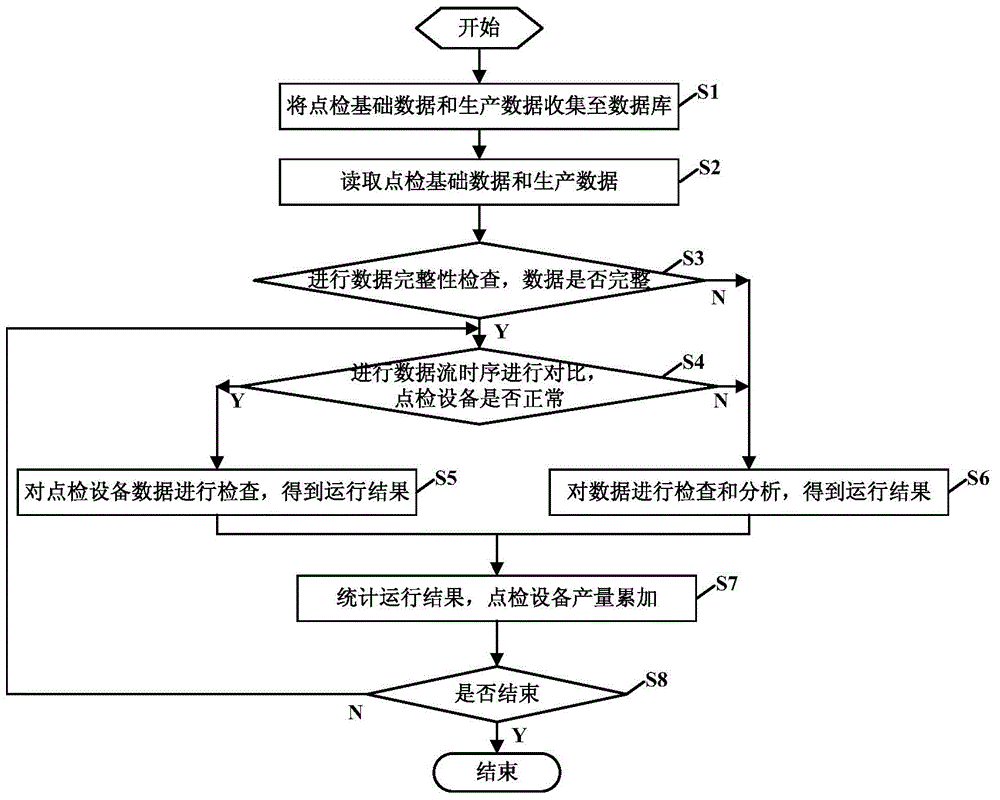

[0044] seefigure 1 As shown, the distributed digital inspection method for sewing machines in the embodiment of the present invention includes the following steps:

[0045] S1: Collect basic inspection data and production data into the database, and go to S2.

[0046] S2: Read the inspection basic data and production data in the database, and transfer to S3.

[0047] S3: Check the data integrity of the inspection basic data and production data, judge whether the inspection basic data and production data are complete according to the inspection results, if so, cache the current inspection basic data and production data, and go to S4, otherwise go to S6 .

[0048] S4: Compare the data flow sequence of the inspection basic data and the production data, and judge whether the equipment to be inspected is normal according to the comparison result,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com