Chlorimuron-ethyl soluble water particulate agent and preparation method thereof

A chlorimuron-methyl-soluble technology, applied in the field of pesticide preparations, can solve the problems of complex production process, slow speed, low safety factor, etc., and achieve the effects of simple preparation process, reduced application amount, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

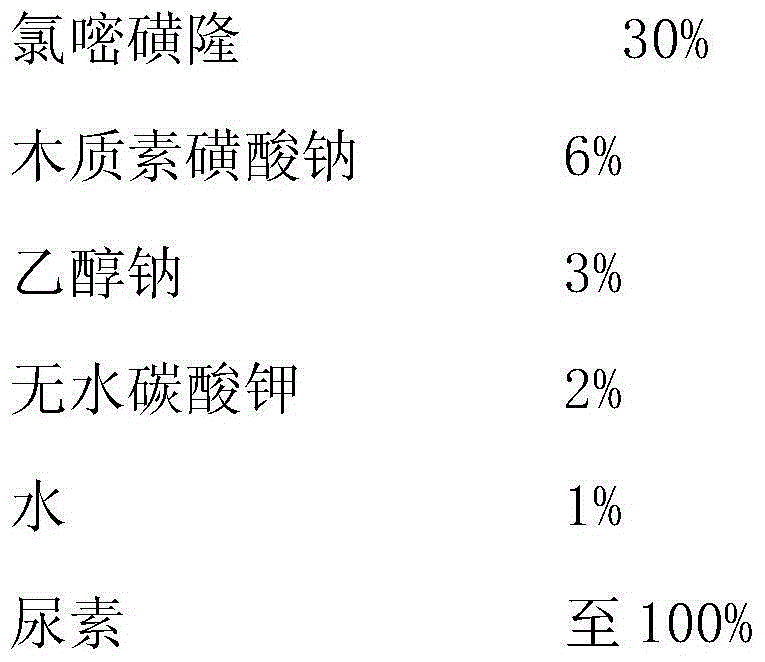

[0033] Embodiment 1: 30% chlorimuron-methyl soluble water granule

[0034]

[0035] According to the above formula, mix chlorimuron-methyl, sodium lignosulfonate, anhydrous potassium carbonate, water, and urea, pulverize each material by air flow, add sodium ethoxide in the mixing kettle to prepare salt, add water and knead, and extrude to make Granules, dried and sieved to obtain the product.

[0036] Determination of physical and chemical properties:

[0037] Moisture content ≤ 2.0%, suspension rate 100%, disintegration time ≤ 1min, dispersibility 100%, solubility in water 2500g / L, qualified accelerated heat storage stability, in line with the quality and technical indicators of soluble water granules.

Embodiment 2

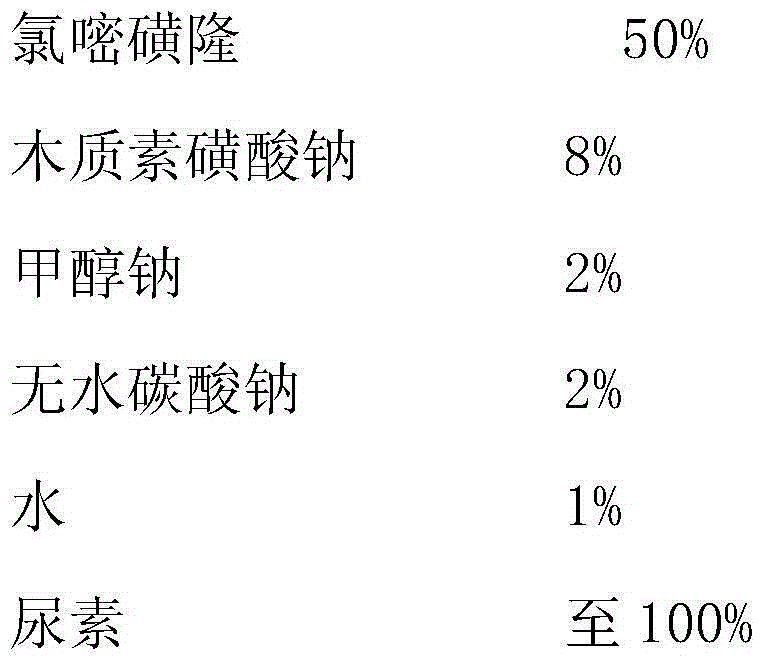

[0038] Embodiment 2: 50% chlorimuron-methyl soluble water granule

[0039]

[0040] According to the above formula, mix chlorimuron-methyl, sodium lignosulfonate, anhydrous potassium carbonate, water, and urea, pulverize each material by air flow, add sodium ethoxide in the mixing kettle to prepare salt, add water and knead, and extrude to make Granules, dried and sieved to obtain the product.

[0041] Determination of physical and chemical properties:

[0042]Moisture content ≤ 2.0%, suspension rate 100%, disintegration time ≤ 1min, dispersibility 100%, solubility in water 2500g / L, qualified accelerated heat storage stability, in line with the quality and technical indicators of soluble water granules.

Embodiment 3

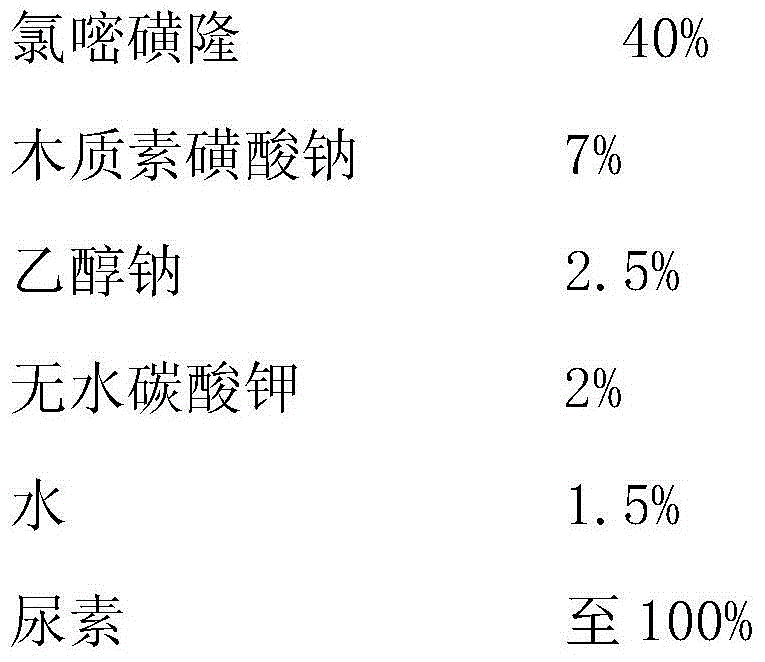

[0043] Embodiment 3: 40% chlorimuron-methyl soluble water granule

[0044]

[0045] According to the above formula, mix chlorimuron-methyl, sodium lignosulfonate, anhydrous potassium carbonate, water, and urea, pulverize each material by air flow, add sodium ethoxide in the mixing kettle to prepare salt, add water and knead, and extrude to make Granules, dried and sieved to obtain the product.

[0046] Determination of physical and chemical properties:

[0047] Moisture content ≤ 2.0%, suspension rate 100%, disintegration time ≤ 1min, dispersibility 100%, solubility in water 2500g / L, qualified accelerated heat storage stability, in line with the quality and technical indicators of soluble water granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com