Laser machining system for forming of pointed end of microprobe

A laser processing and micro-probe technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the influence of the probe tip, the size of the heating area cannot be adjusted according to the processing requirements, and the tip forming consistency and repeatability are poor, etc. problems, to achieve precise control of machining power and action time, easy machining power and action time, good forming consistency and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

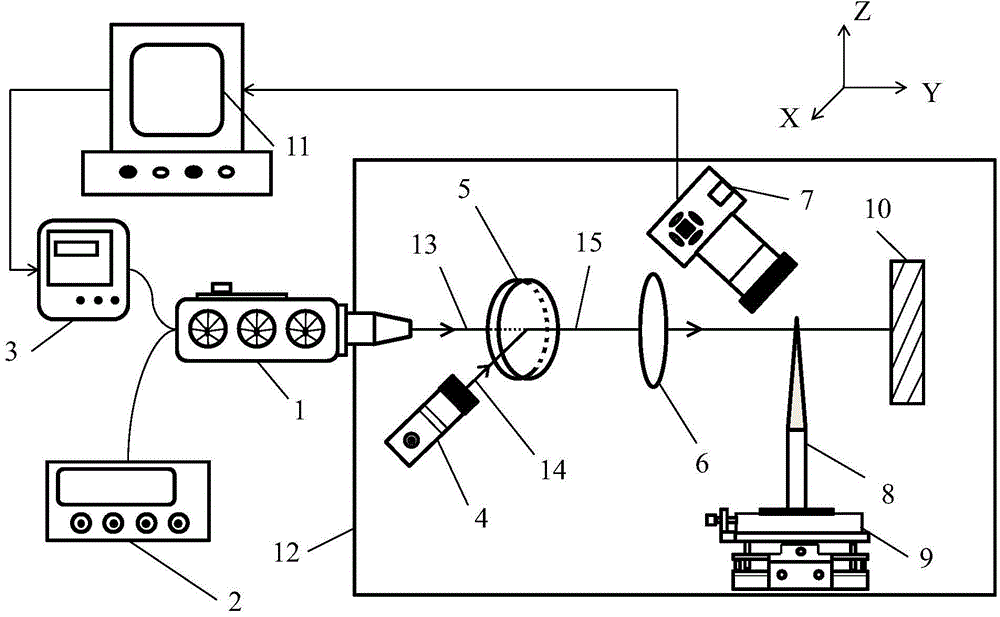

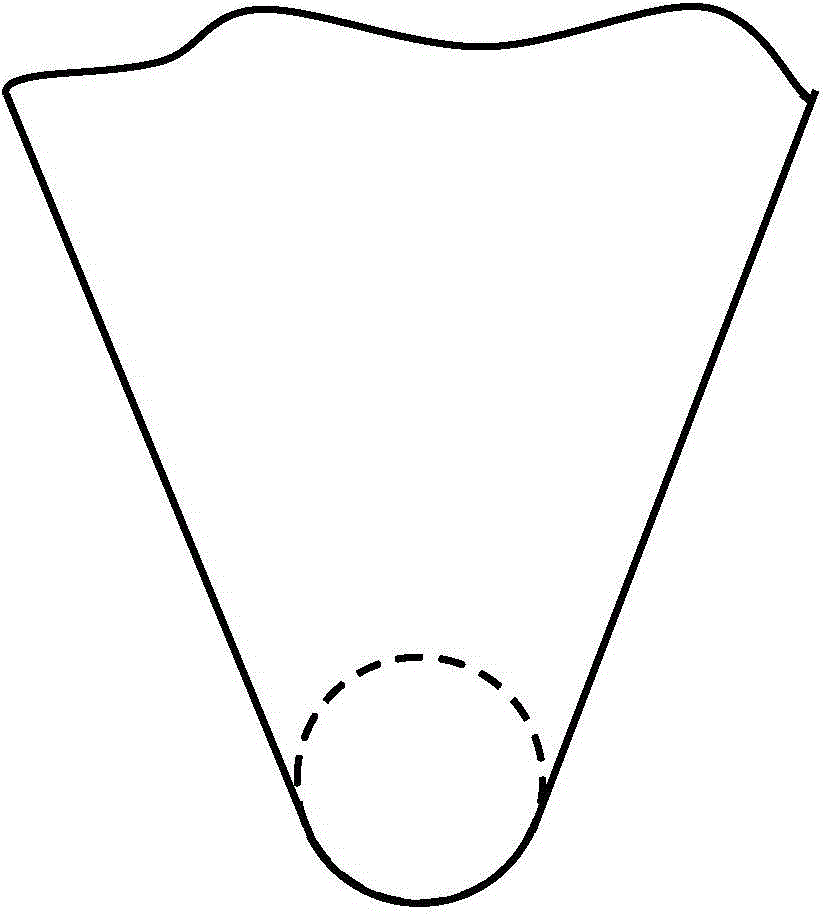

[0028] Such as figure 1 Shown: the present invention relates to a microprobe tip shaping laser processing system, comprising: CO 2 Laser (1), DC power supply (2), power controller (3), laser pointer (4), beam combiner (5), focusing lens (6), microscopic imaging equipment (7), microprobe blank (8), probe position adjustment module (9), laser absorber (10), signal analysis and processing module (11), protective glass cover (12), etc. Described micro-imaging equipment (7) takes CCD micro-imager as example, described microprobe blank (8) takes glass probe as example, and described probe position adjustment module (9) uses precision three-dimensional The displacement platform is taken as an example, and the signal analysis and processing module (11) is described by taking a computer as an example. Concrete process of the present invention can be divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com