Bulk polymerization method with constant-rate dropwise adding of monomer

A bulk polymerization and drop-adding technology, which is applied in the field of bulk polymerization, can solve problems such as the difficulty of heat dissipation in bulk polymerization, and achieve the effects of wide application range, improved strength, and uniform materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

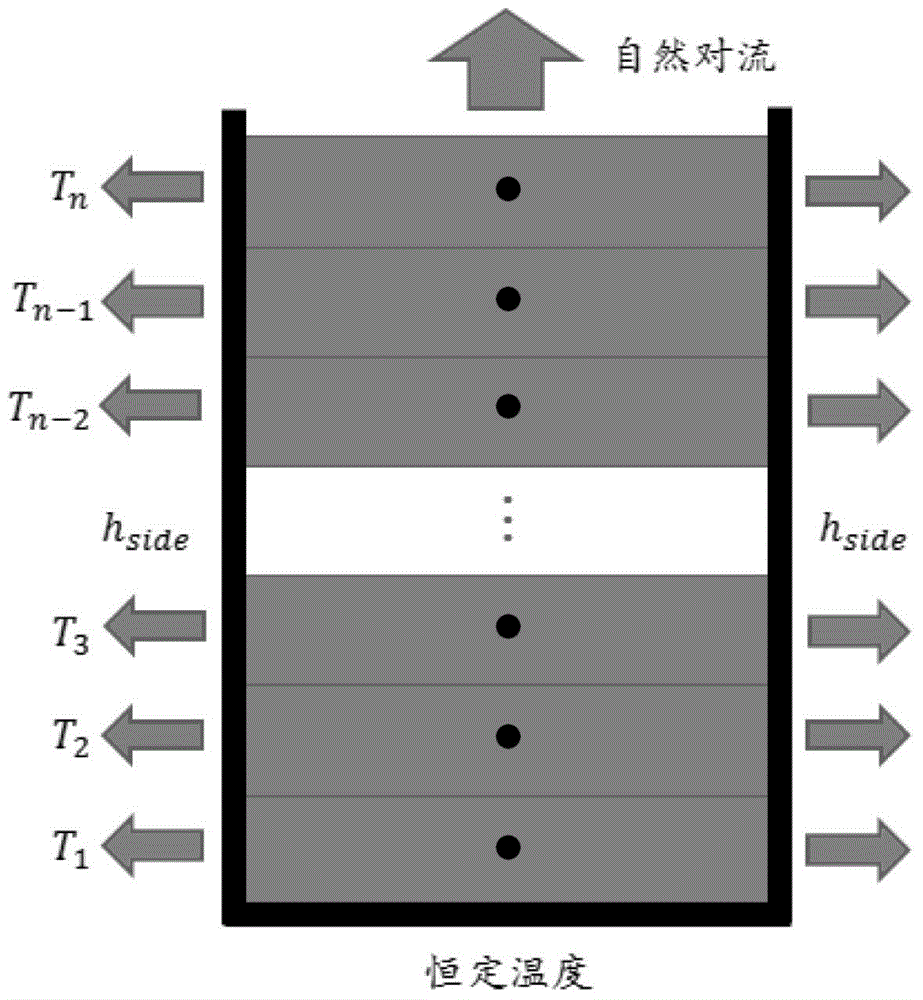

Method used

Image

Examples

Embodiment 1

[0061] (1) Fully mix 2.88mol styrene and 0.12mol divinylbenzene, add 4.233g benzoyl peroxide (BPO) (its molar concentration in the total reactant is 0.05mol / L) as initiator and fully Stir, and fill with argon for 30 minutes after it is completely dissolved to fully remove the dissolved oxygen in the monomer. All reactants were stored in syringes mounted on micropropellers and kept at low temperatures.

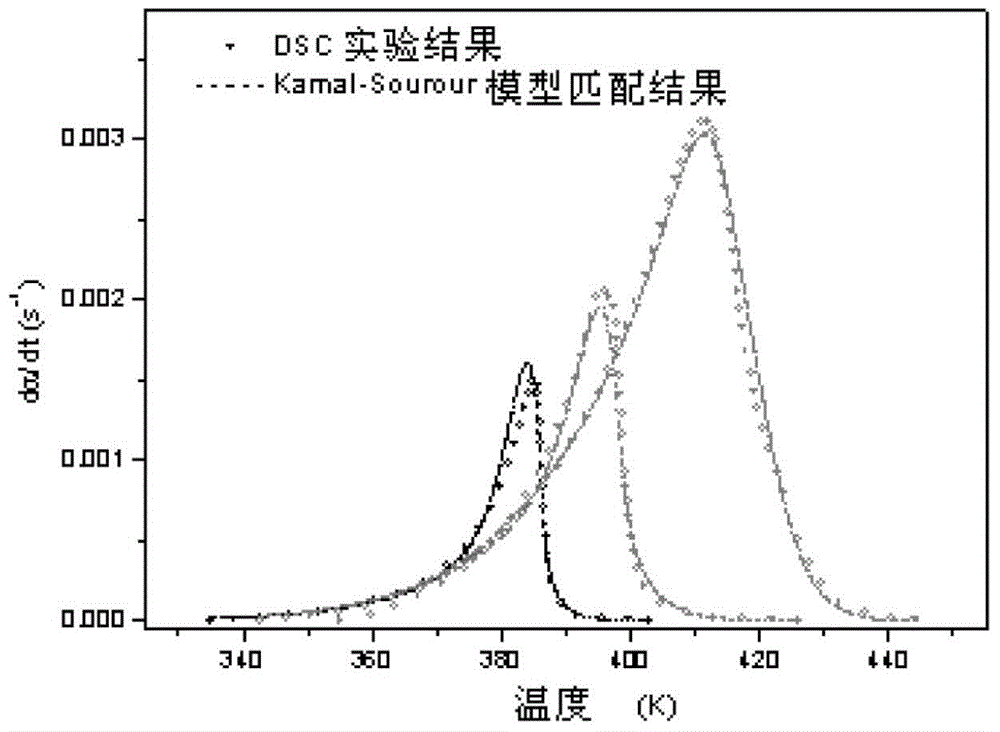

[0062] (2) Using DSC (Dynamic Differential Scanning Calorimetry) to test the reaction rate curves of the reactants at the heating rates of 1° C. / min, 2° C. / min and 5° C. / min respectively. Moreover, the polymerization reaction enthalpy ΔH was also measured by DSC to be 600 J / g.

[0063] (3) Combine the curves obtained in step (2) in one graph, and use the Kamal-Sourour model:

[0064] dα dt = ( A 1 exp ( - ...

Embodiment 2

[0080] Fully mix 2.94mol styrene and 0.06mol divinylbenzene, add 4.209g BPO (the molar concentration in the total reactant is 0.05mol / L) as an initiator and stir well, and fill with argon after it is completely dissolved 30 minutes to fully remove the dissolved oxygen in the monomer. All reactants were stored in syringes mounted on micropropellers and kept at low temperatures.

[0081] DSC (Dynamic Differential Scanning Calorimetry) was used to test the polymerization enthalpy of the reactants, and the reaction rate curves at different heating rates of 1 °C / min, 2 °C / min and 5 °C / min.

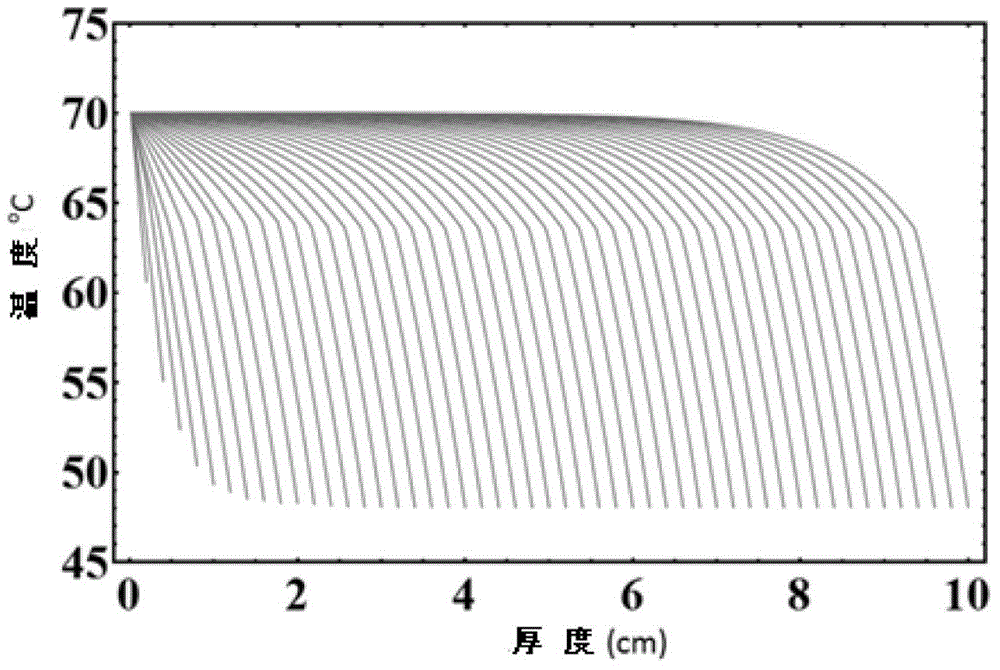

[0082] The Kamal-Sourour model was used to optimize the fitting of the rate curve, and the obtained parameters and ΔH were substituted into the exothermic model, and combined with the Fourier heat transfer model, the dropping rate at 70°C was determined to be 5.5ml / h , the corresponding growth rate in the thickness direction is 0.171cm / h (reactor with a diameter of 6.4cm).

[0083]Vacuumize a...

Embodiment 3

[0086] Mix 2.97mol of styrene and 0.03mol of divinylbenzene, add 4.197g of BPO (the molar concentration in the total reactant is 0.05mol / L) as an initiator and stir well, and fill with argon after it is completely dissolved 30 minutes to fully remove the dissolved oxygen in the monomer. All reactants were stored in syringes mounted on micropropellers and kept at low temperatures.

[0087] DSC (Dynamic Differential Scanning Calorimetry) was used to test the polymerization enthalpy of the reactants, and the reaction rate curves at different heating rates of 1 °C / min, 2 °C / min and 5 °C / min.

[0088] The rate curve was optimally fitted using the Kamal-Sourour model, and the obtained parameters and ΔH were substituted into the exothermic model, and combined with the Fourier heat transfer model to determine that the dropping rate at 70°C was 7ml / h. The corresponding growth rate in the thickness direction is 0.218cm / h (reactor with a diameter of 6.4cm).

[0089] Vacuumize the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com