Medical material suitable for infusion bags and preparation method thereof

A technology for infusion bags and antioxidants, applied in the field of medical materials for infusion bags and its preparation, can solve the problems of tensile strength drop, deformation, and easy cracking of the bag body of the infusion bag, and achieve the effect of increasing the elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

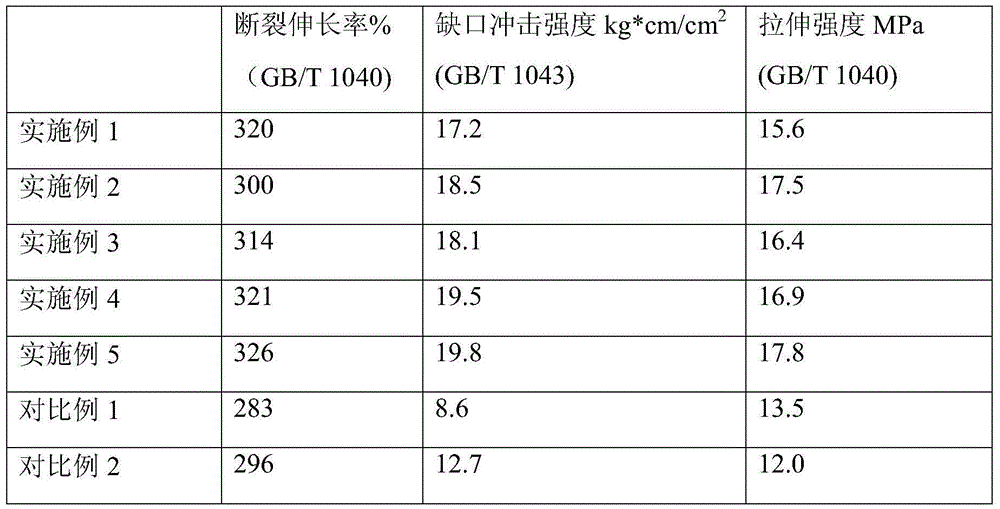

Examples

Embodiment 1

[0017] A medical material suitable for infusion bags, consisting of the following components in parts by mass: 58 parts of polyethylene, 13 parts of distearyl pentaerythritol diphosphite, 4 parts of azobisisoheptanonitrile, calcium stearate 5 parts, 20 parts of acetone, 11 parts of epoxidized soybean oil, 14 parts of dibutyl sebacate, 12 parts of dioctyl phthalate, 24 parts of ethylene-butene copolymer.

[0018] Preparation:

[0019] (1) According to the above mass parts, divide acetone into two parts on average, add polyethylene, distearyl pentaerythritol diphosphite, azobisisoheptanonitrile, the first part of acetone, sebacic acid diphosphite into the mixing mixer Butyl ester, dioctyl phthalate, and ethylene-butene copolymer were stirred at a temperature of 80°C at a rate of 800r / min to obtain a mixture 1;

[0020] (2) Add the second part of acetone, calcium stearate and epoxidized soybean oil to the mixed material 1 obtained in step (1), stir at 120° C. for 50 minutes, and...

Embodiment 2

[0023] A medical material suitable for infusion bags, consisting of the following components in parts by mass: 76 parts of polyethylene, 28 parts of distearyl pentaerythritol diphosphite, 11 parts of azobisisoheptanonitrile, calcium stearate 17 parts, 42 parts of acetone, 25 parts of epoxidized soybean oil, 21 parts of dibutyl sebacate, 19 parts of dioctyl phthalate, 36 parts of ethylene-butene copolymer.

[0024] Preparation:

[0025] (1) According to the above mass parts, divide acetone into two parts on average, add polyethylene, distearyl pentaerythritol diphosphite, azobisisoheptanonitrile, the first part of acetone, sebacic acid diphosphite into the mixing mixer Butyl ester, dioctyl phthalate, and ethylene-butene copolymer were stirred at a temperature of 100°C at a rate of 1000r / min to obtain a mixture 1;

[0026] (2) Add the second part of acetone, calcium stearate and epoxidized soybean oil to the mixed material 1 obtained in step (1), and stir for 60 minutes at a te...

Embodiment 3

[0029] A medical material suitable for infusion bags, consisting of the following components in parts by mass: 63 parts of polyethylene, 18 parts of distearyl pentaerythritol diphosphite, 8 parts of azobisisobutyronitrile, calcium stearate 7 parts, 26 parts of acetone, 15 parts of epoxidized soybean oil, 17 parts of dibutyl sebacate, 14 parts of dioctyl phthalate, and 28 parts of ethylene-butene copolymer.

[0030] Preparation:

[0031] (1) According to the above mass parts, divide acetone into two parts on average, add polyethylene, distearyl pentaerythritol diphosphite, azobisisobutyronitrile, the first part of acetone, sebacic acid di Butyl ester, dioctyl phthalate, and ethylene-butene copolymer were stirred at a temperature of 85°C at a rate of 850r / min to obtain a mixture 1;

[0032] (2) Add the second part of acetone, calcium stearate and epoxidized soybean oil to the mixed material 1 obtained in step (1), stir at 130° C. for 55 minutes, and the speed is 1900 r / min to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com