Medium-pressure water-tree-retardant crosslinked polyethylene cable material and cable using cable material

A cross-linked polyethylene, water-tree-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as the problem of cable water tree production, and achieve excellent water-blocking effect, stable cable performance, and cable Better electrical/mechanical/environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Implementation example 1 is an implementation example of the cable material of the present invention, and implementation example 2 and implementation example 3 are implementation examples of the cable of the present invention.

[0044] Implementation Example 1

[0045] The medium-voltage water-tree-resistant cross-linked polyethylene cable material is characterized in that it is composed of the following raw materials and contents in parts by weight:

[0046] Low-density polyethylene: 40-60 parts;

[0047] Medium density polyethylene: 15 to 30 parts;

[0048] Polypropylene: 5-10 parts;

[0049] Polyolefin elastomer: 3 to 5 parts;

[0050] Titanium dioxide: 1 to 3 parts;

[0051] Polyethylene wax or paraffin: 4 to 6 parts;

[0052] Carbon black: 1 to 3 parts;

[0053] Dicumyl peroxide: 0.5 to 1.5 parts;

[0054] Hydroxyethyl acrylate or methacrylate: 15-25 parts;

[0055] Antioxidant 168 or Antioxidant 1010: 0.8-2.0 parts;

[0056] Dimethylaminoethyl methacryl...

Embodiment 2

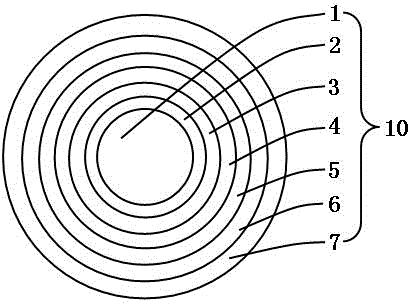

[0065] please see figure 1 , the anti-water tree XLPE cable 10 has a single conductor 1 and an outer sheath 7 located outside the conductor, and is characterized in that the conductor is extruded and coated with an insulating layer 2, and the insulating layer is coated with a shielding layer 3, There is a first water blocking layer 4 outside the shielding layer, an inner sheath 5 outside the first water blocking layer, a second water blocking layer 6 outside the inner sheath, and the outer sheath is extruded and coated on the outside of the second water blocking layer; The material of the inner sheath and the outer sheath is commercially available XLPE cable material or the medium-voltage water-tree-resistant XLPE cable material described in Example 1, and the maximum gap between the insulating layer and the conductor is 0.1 μm ; From the inner sheath to the first water-blocking layer, the first water-blocking layer is air-tight and liquid-tight; on any cross-section perpendic...

Embodiment 3

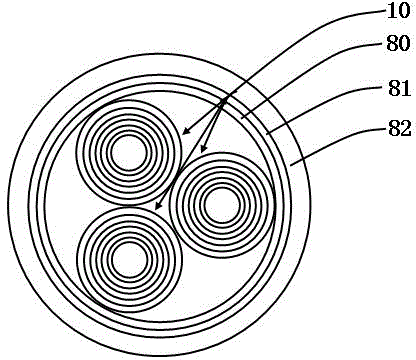

[0075] please see figure 2 , a three-core structure anti-water tree XLPE cable, which is characterized in that it contains three anti-water tree XLPE cables in Example 1, and the three anti-water tree XLPE cables are placed in pairs tangentially, The three anti-water tree XLPE cables have a position fixing layer 80 on the outside, a third water blocking layer 81 coated on the outside of the position fixing layer, and a water blocking sheath 82 on the outside of the third water blocking layer.

[0076] The above-mentioned three-core structure anti-water tree XLPE cable is characterized in that the material of the position-fixing layer is polyester tape or non-woven fabric or water-blocking tape.

[0077] The above-mentioned three-core structure anti-water tree XLPE cable is characterized in that the material of the third water blocking layer is aluminum strip, steel strip or copper strip.

[0078] The above-mentioned three-core structure anti-water tree cross-linked polyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com