Polylactic acid composite material sheet for plastic uptake and preparation method of sheet

A technology of composite material and polylactic acid, which is applied in the field of polylactic acid composite sheet for plastic absorption and its preparation, can solve the problems of poor melt viscoelasticity, small number of branched molecular chains, low melt viscosity and melt strength, etc. , to achieve the effects of easy processing and molding, excellent physical and chemical properties, and good biological and chemical degradation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

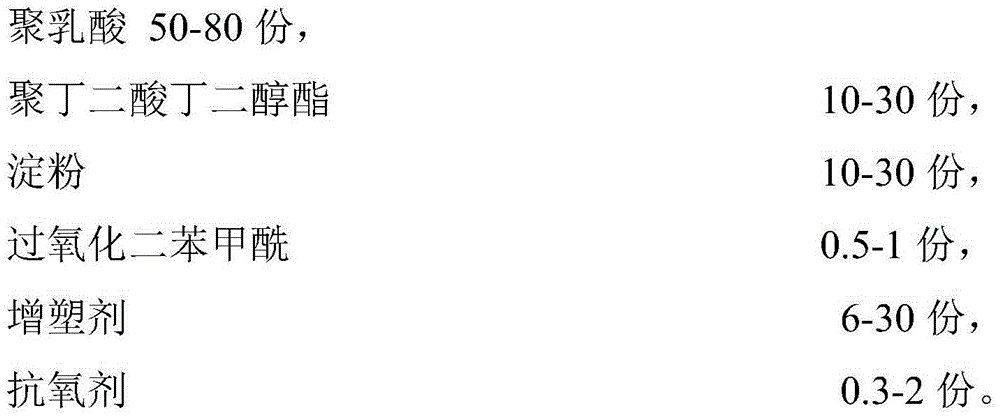

[0022] The raw material components are:

[0023]

[0024] Mix starch and plasticizer evenly in proportion. The resulting mixture was stored sealed in a plastic bag. A single-screw extruder is used for extrusion molding, the screw temperature of the extruder is 85° C., and the screw speed is 160 rpm. The prepared thermoplastic starch granules were vacuum dried at room temperature for 12 h. PLA and antioxidant were vacuum-dried at 70°C for 15h, and cooled in vacuum. PBS particles were dried in a common blast drying oven at 60°C for 15h. Mix PLA, PBS, BPO and antioxidant in a high-speed blender according to the proportion. Then use a co-rotating twin-screw extruder to extrude and granulate. The temperature of each section of the extruder screw is: 80°C, 85°C, 90°C, 95°C, 105°C, 110°C, 105°C, and the screw speed is 180rpm. The obtained modified polylactic acid particles were vacuum dried at 60° C. for 18 h. The prepared thermoplastic starch granules and modified polylactic...

Embodiment 2

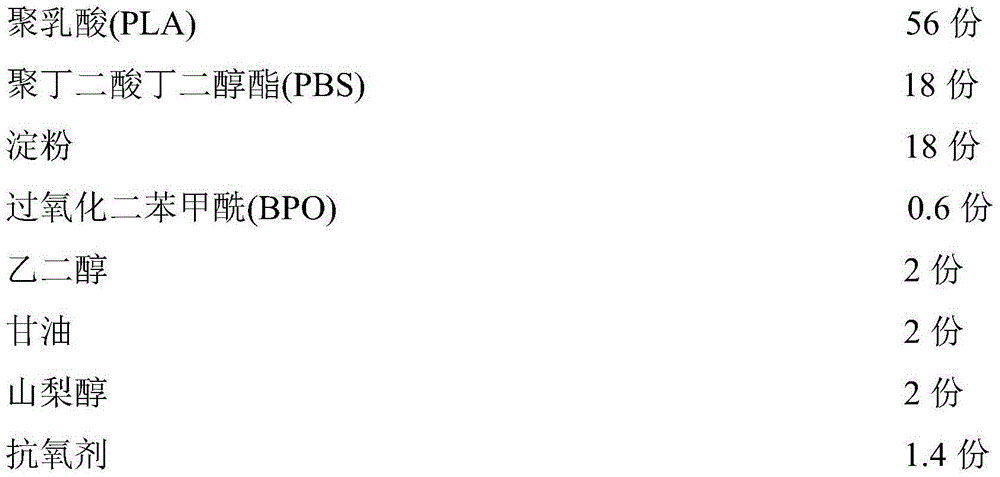

[0026] The raw material components are:

[0027]

[0028] Mix starch and plasticizer evenly in proportion. The resulting mixture was stored sealed in a plastic bag. A single-screw extruder is used for extrusion molding, the screw temperature of the extruder is 90° C., and the screw speed is 180 rpm. The prepared thermoplastic starch granules were vacuum dried at room temperature for 12 h. PLA and antioxidant were vacuum-dried at 70°C for 15h, and cooled in vacuum. PBS particles were dried in a common blast drying oven at 60°C for 15h. Mix PLA, PBS, BPO and antioxidant in a high-speed blender according to the proportion. Then use a co-rotating twin-screw extruder to extrude and granulate. The temperature of each section of the extruder screw is: 80°C, 90°C, 95°C, 100°C, 110°C, 115°C, 110°C, and the screw speed is 200rpm. The obtained modified polylactic acid particles were vacuum dried at 60° C. for 18 h. The prepared thermoplastic starch granules and modified polylacti...

Embodiment 3

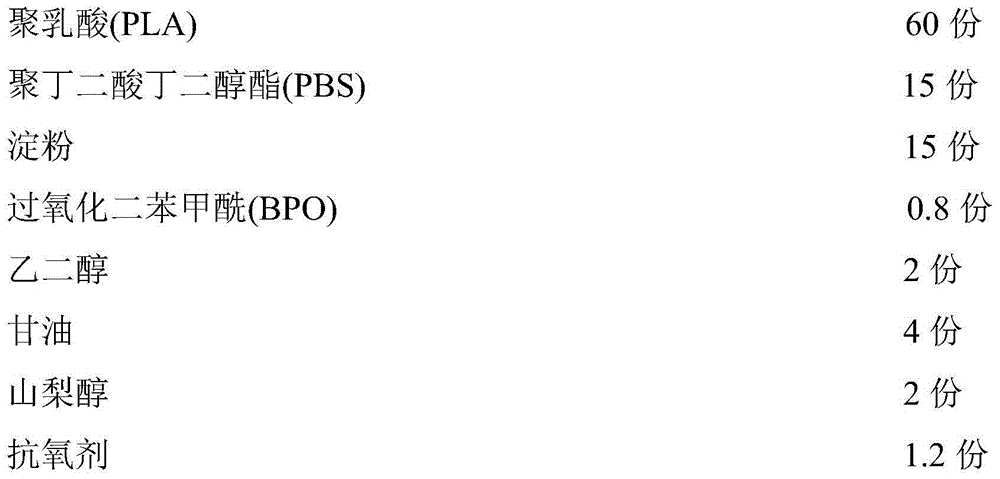

[0030] The raw material components are:

[0031]

[0032]Mix starch and plasticizer evenly in proportion. The resulting mixture was stored sealed in a plastic bag. A single-screw extruder is used for extrusion molding, the screw temperature of the extruder is 95° C., and the screw speed is 200 rpm. The prepared thermoplastic starch granules were vacuum dried at room temperature for 12 h. PLA and antioxidant were vacuum-dried at 70°C for 15h, and cooled in vacuum. PBS particles were dried in a common blast drying oven at 60°C for 15h. Mix PLA, PBS, BPO and antioxidant in a high-speed blender according to the proportion. Then use a co-rotating twin-screw extruder to extrude and granulate. The temperature of each section of the extruder screw is: 85°C, 95°C, 100°C, 110°C, 120°C, 125°C, 120°C, and the screw speed is 220rpm. The obtained modified polylactic acid particles were vacuum dried at 60° C. for 18 h. The prepared thermoplastic starch granules and modified polylacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com