Important component of crack-resistant insulated flame-retardant building material coating

A kind of composition, anti-cracking technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of unsatisfactory heat insulation effect, lack of anti-cracking performance, high addition amount, etc., to achieve good elasticity, non-toxic and tasteless finished products, Good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

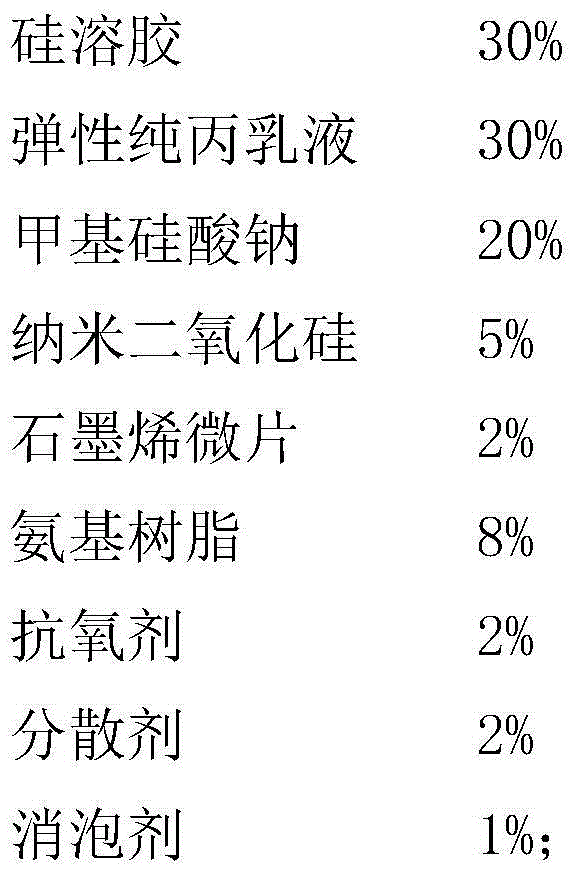

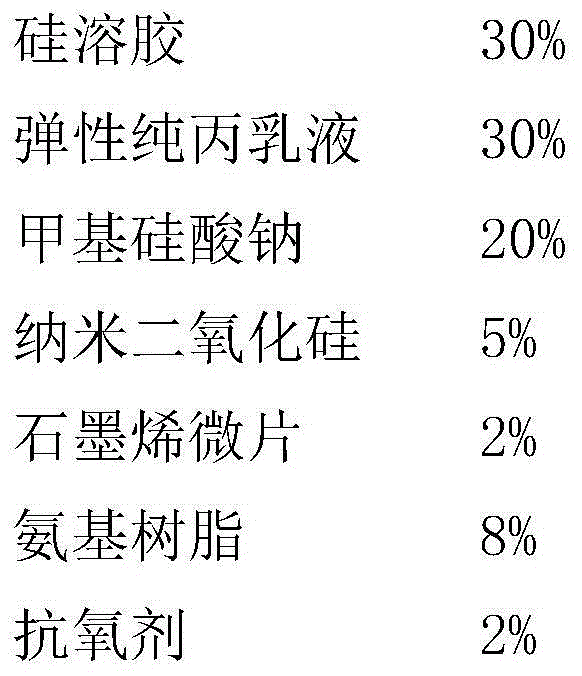

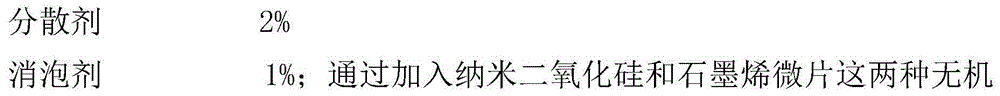

[0021] An important component of an anti-crack, thermal insulation and flame-retardant building material coating is made of the following components by weight percentage:

[0022]

[0023]

[0024] Non-metallic materials to improve the crack resistance of coatings.

[0025] The above-mentioned graphene microsheets are grown in a three-dimensional honeycomb manner (like diamond ore), and the four valence electrons of each carbon atom form covalent bonds and are bound, which cannot form a directional mobile electron flow, so It cannot conduct electricity. After the generation, the graphene carbon crystal is ground by wet nano-grinding method in a single direction to produce graphene microflakes with a nanometer thickness and a micronized area; adding graphene microchips to the coating can greatly improve the fusion of the coating. Performance, with very good crack resistance.

[0026] The preparation method of above-mentioned nano silicon dioxide is as follows:

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com