Environment-friendly composite snow-melting agent for emulsified asphalt, and preparation method and application method of environment-friendly composite snow-melting agent

A technology of emulsified asphalt and snow-melting agent, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of long time required to melt ice and snow, inability to melt ice and snow, and environmental pollution, so as to save consumption, reduce traffic jams, and speed up The effect of snow removal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

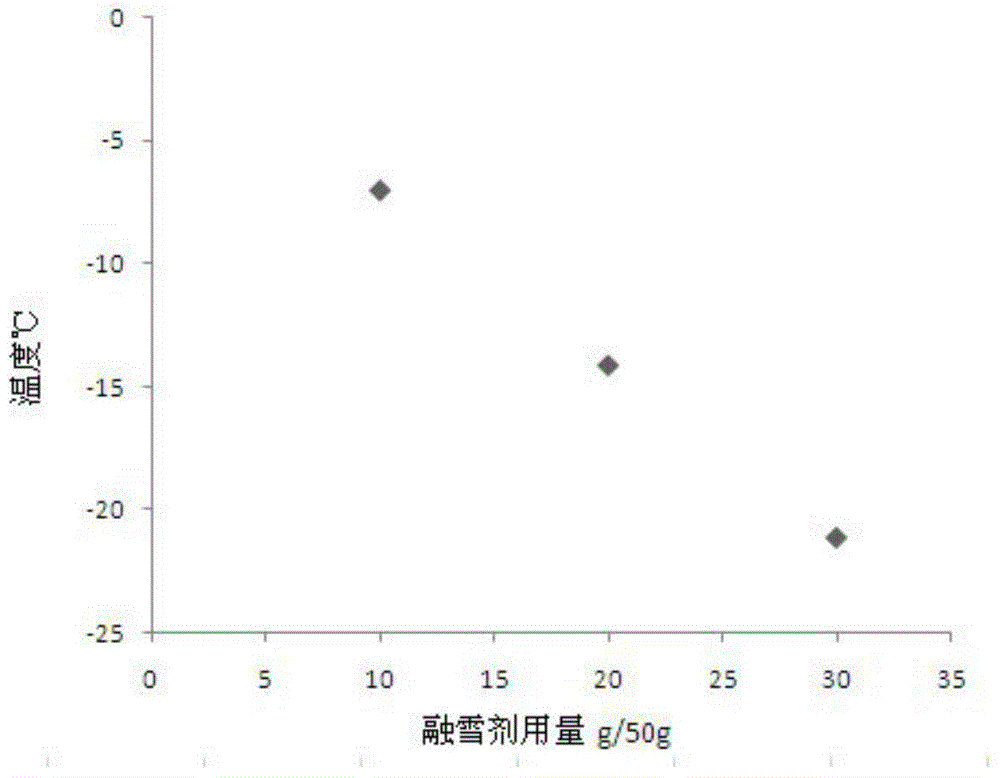

Embodiment 1

[0033] The preparation method and use method of an environmentally-friendly composite snow melting agent for emulsified asphalt of the present invention, the specific steps are as follows:

[0034] (1) Weigh 8 g of magnesium acetate and 2 g of calcium acetate, mix and stir to obtain a mixed acetate solid.

[0035] (2) Dissolve the obtained mixed acetate solid in a mixed solution of 9 ml of ethylene glycol and 1 ml of glycerol, stir and mix to obtain a mixed system.

[0036] (3) Heat 500 ml of water to 80°C, add 3g of algae gel, and stir at 80°C for 20 minutes to obtain an algae gel solution.

[0037] (4) Take 10 ml of the prepared algae gel solution, add it to the mixing system prepared in (2) while it is hot, and stir and mix to obtain an environmentally friendly composite snow melting agent.

[0038] (5) When in use, the obtained environmentally friendly composite snow melting agent is added to 50 g of emulsified asphalt, stirred and mixed, and allowed to stand for 24 hours to obtain ...

Embodiment 2

[0040] The preparation method and use method of an environmentally-friendly composite snow melting agent for emulsified asphalt of the present invention, the specific steps are as follows:

[0041] (1) Weigh 16.7 g of magnesium acetate and 3.3 g of calcium acetate, mix and stir to obtain a mixed acetate solid.

[0042] (2) Dissolve the obtained mixed acetate solid in a mixed solution dissolved in 6.7 ml of ethylene glycol and 3.3 ml of glycerol, stir and mix well to obtain a mixed system.

[0043] (3) Heat 500 ml of water to 80° C., add 3 g of algae gel, mix and stir, keep at a constant temperature for 20 minutes to obtain an algae gel solution.

[0044] (4) Take 10 ml of the prepared algae gel solution, add it to the mixing system obtained in (2) while it is hot, and stir and mix to obtain an environmentally friendly composite snow melting agent.

[0045] (5) When in use, the obtained environmentally friendly composite snow melting agent is added to 50 g of emulsified asphalt, stirred ...

Embodiment 3

[0047] The method for preparing and using an environmentally-friendly composite snow-melting agent for emulsified asphalt of the present invention has the following specific steps:

[0048] (1) Weigh 25 g of magnesium acetate and 5 g of calcium acetate, mix and stir to obtain a mixed acetate solid.

[0049] (2) Dissolve the obtained mixed acetate solid in a mixed solution dissolved in 8 ml of ethylene glycol and 2 ml of glycerol, stir and mix to obtain a mixed system.

[0050] (3) Heat 500 ml of water to 80° C., add 3 g of algae gel, mix and stir, keep at a constant temperature for 20 minutes to obtain an algae gel solution.

[0051] (4) Take 10 ml of the prepared algae gel solution, add it to the mixing system obtained in (2) while it is hot, and stir and mix to obtain an environmentally friendly composite snow melting agent.

[0052] (5) When in use, the obtained environmentally friendly composite snow melting agent is added to 50 g of emulsified asphalt, stirred and mixed, and allowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com