A monitoring system for a reciprocating compressor

A monitoring system and compressor technology, which is applied in the direction of liquid variable displacement machinery, pump testing, mechanical equipment, etc., can solve the problems of insufficient maintenance, accidents caused by insufficient maintenance, waste of resources and costs, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail through the following examples, which are illustrative rather than restrictive, and cannot limit the protection scope of the present invention.

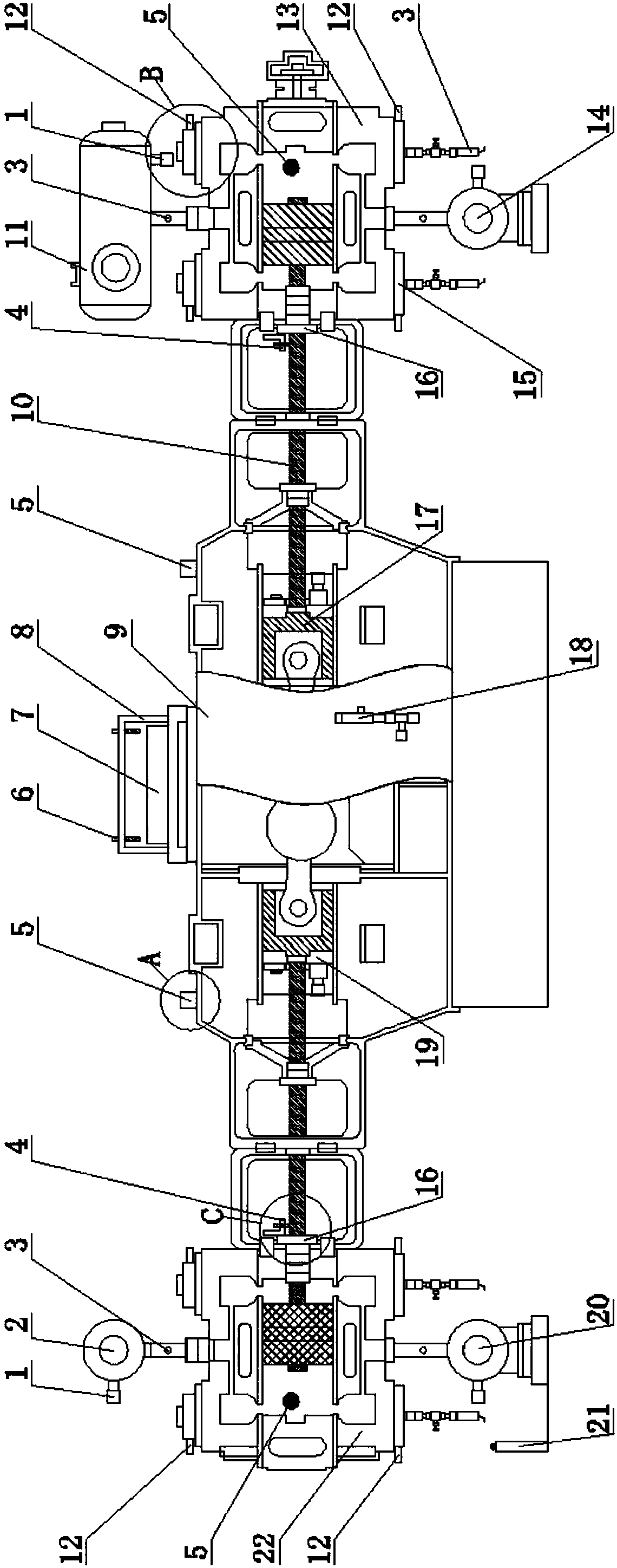

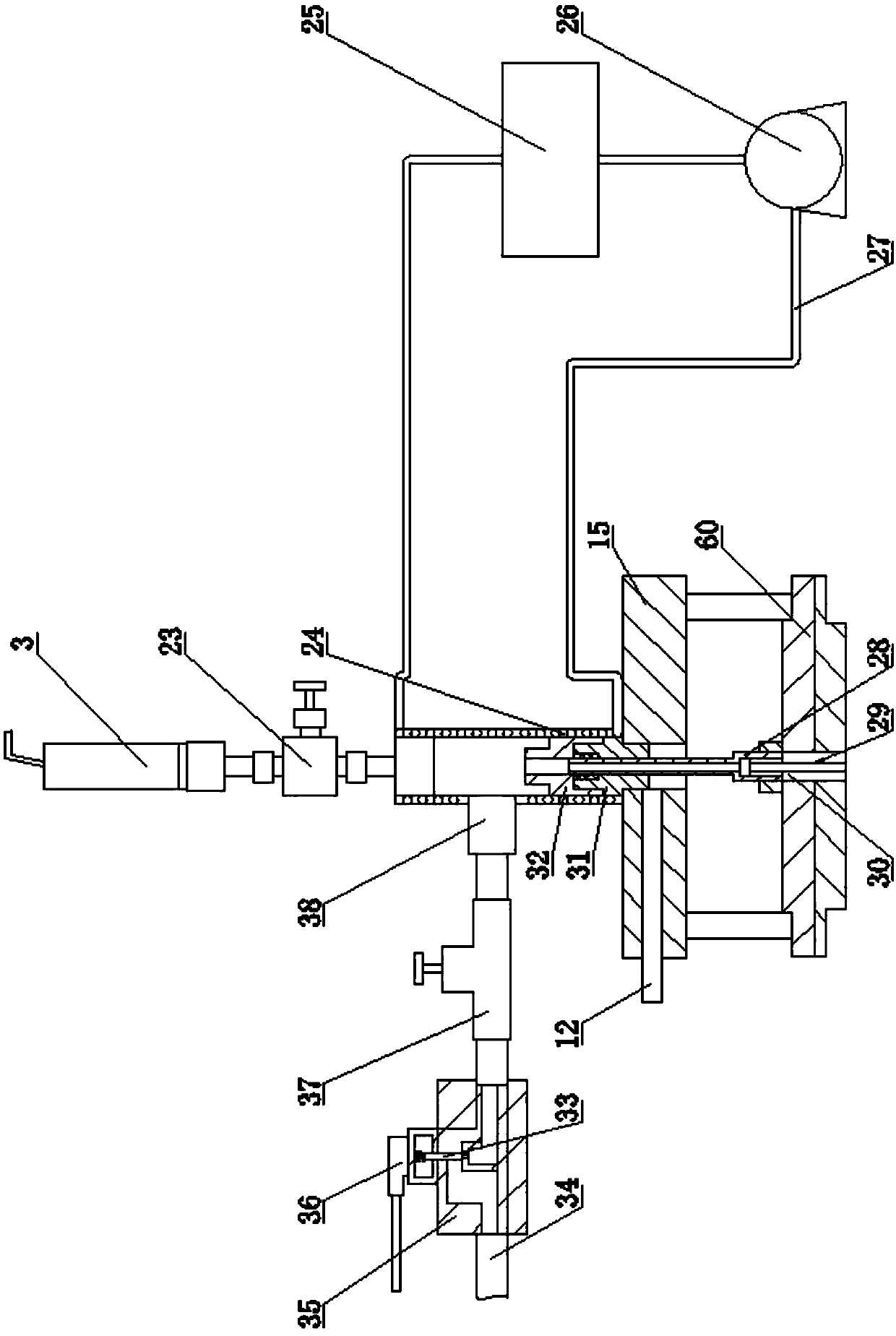

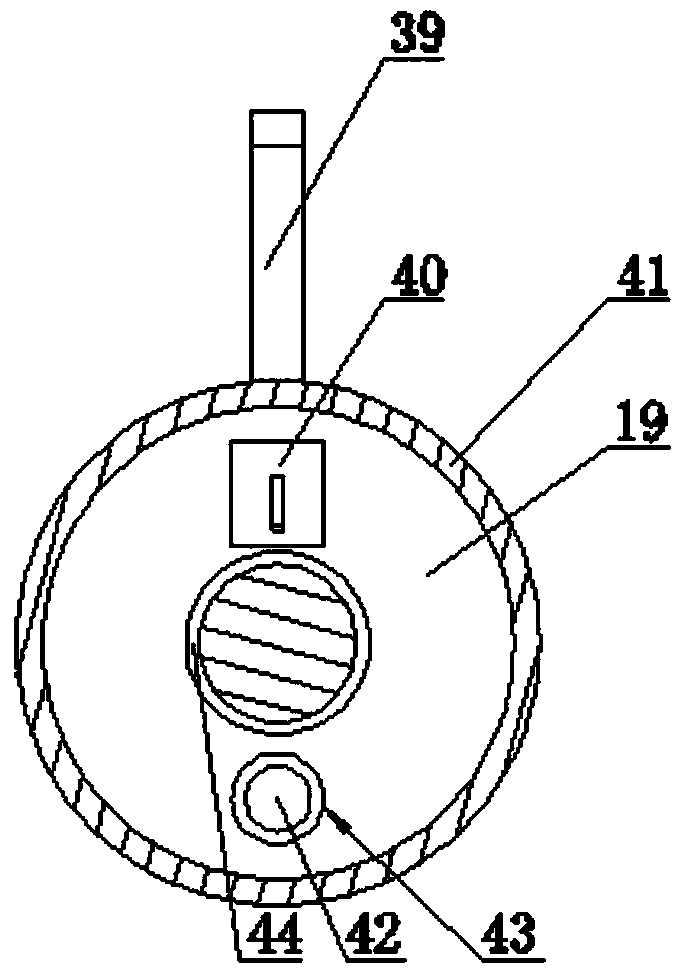

[0036] A monitoring system for a reciprocating compressor, including a reciprocating compressor, the reciprocating compressor includes a body 9, the body is communicated with an overflow valve, the upper end of the body is equipped with a turntable 7, a protective cover 8, the body A section of cylinder 13 and a section of cylinder 22 are respectively installed on both sides, and the section of cylinder is connected and installed with a section of cylinder intake buffer tank 11 and a section of cylinder exhaust buffer tank 14 through a pipeline, and the section of cylinder is connected and installed through a pipeline There are a two-stage cylinder intake buffer tank 2 and a two-stage cylinder exhaust buffer tank 20, and a pressure probe 3 is installed on the outer end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com