Device and method for deep waste heat recovery and collaborative removal of pollutants in flue gas

A technology of waste heat recovery and waste heat recovery system, which is applied in the direction of combination device, separation method, chemical instrument and method, etc., to achieve the effect of reducing consumption, reducing coal consumption for power generation, and eliminating gypsum rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

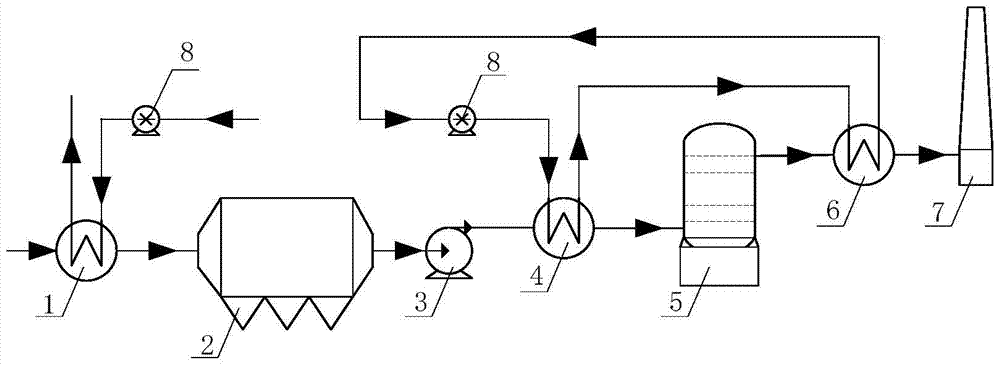

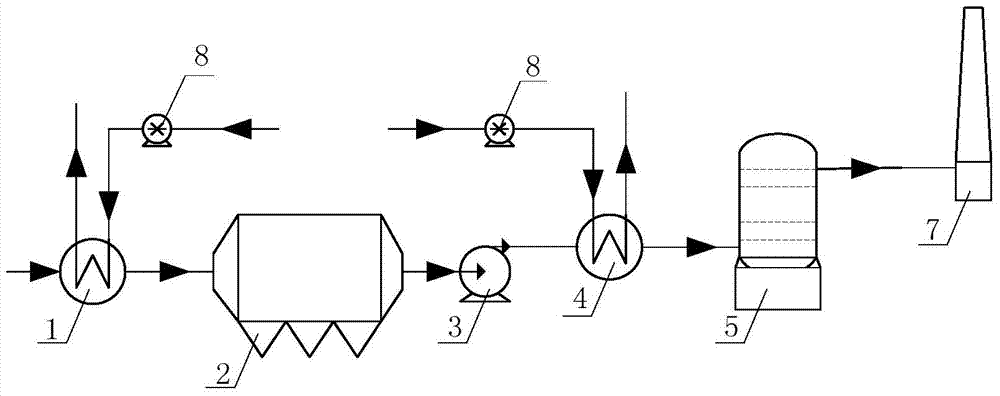

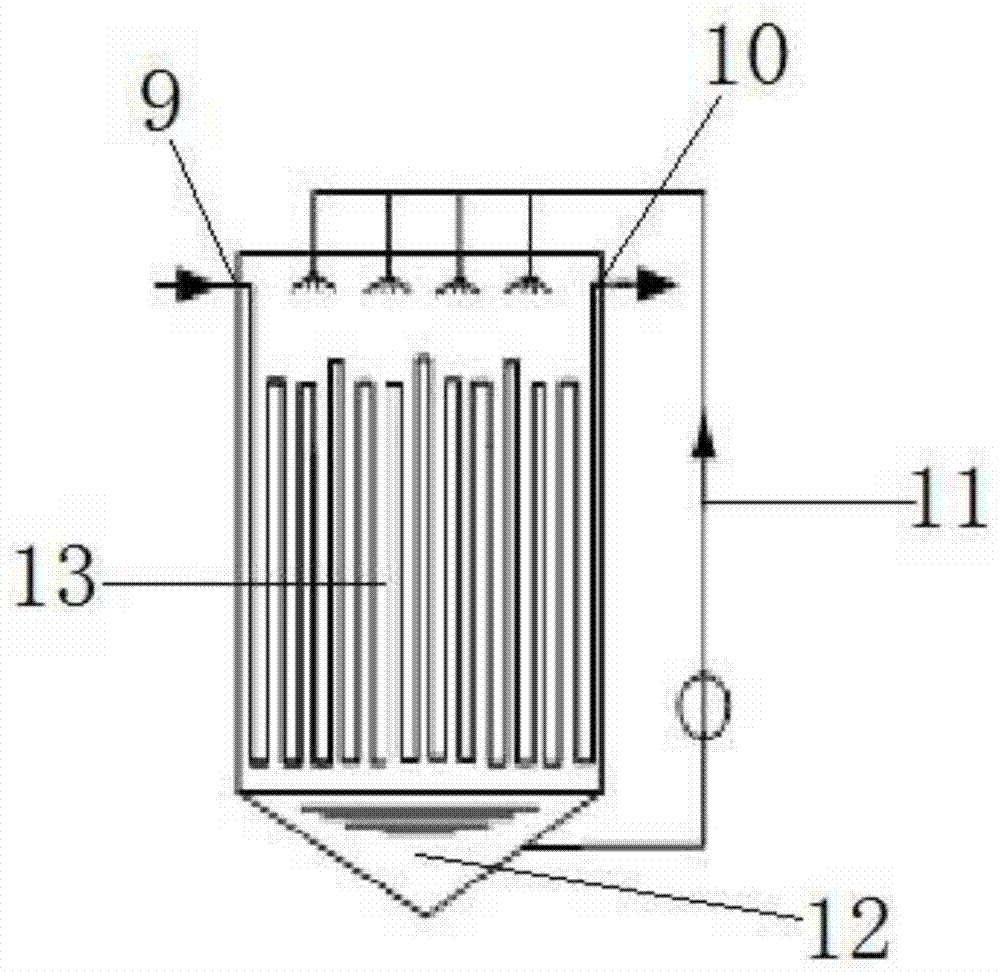

[0033] like figure 1 , a deep waste heat recovery collaborative removal of pollutants in flue gas including SO 2 , soot, PM2.5, SO 3and Hg device, which includes a first-level waste heat recovery system 1, an electrostatic dust removal mercury removal system 2, a fan 3, a deep waste heat recovery collaborative multi-removal system 4, a high-efficiency desulfurization and dust removal system 5, a flue gas reheating system 6, and a chimney 7, According to the flue gas treatment process, the device is equipped with a first-level waste heat recovery system 1, an electrostatic precipitator and mercury removal system 2, a deep waste heat recovery collaborative multi-removal system 4, a high-efficiency desulfurization and dust removal system 5, a flue gas reheating system 6, and a chimney 7 The first-level waste heat recovery system 1 is set at the front of the electrostatic precipitator and mercury removal system 2, and the deep waste heat recovery and multi-removal system 4 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com