A thin film high temperature photoelectric physical property testing device

A physical property test, thin film technology, applied in the field of thin film high-temperature photoelectric physical property test devices, to achieve a wide temperature measurement range, ensure accuracy and precision, and improve the effect of physical property measurement capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

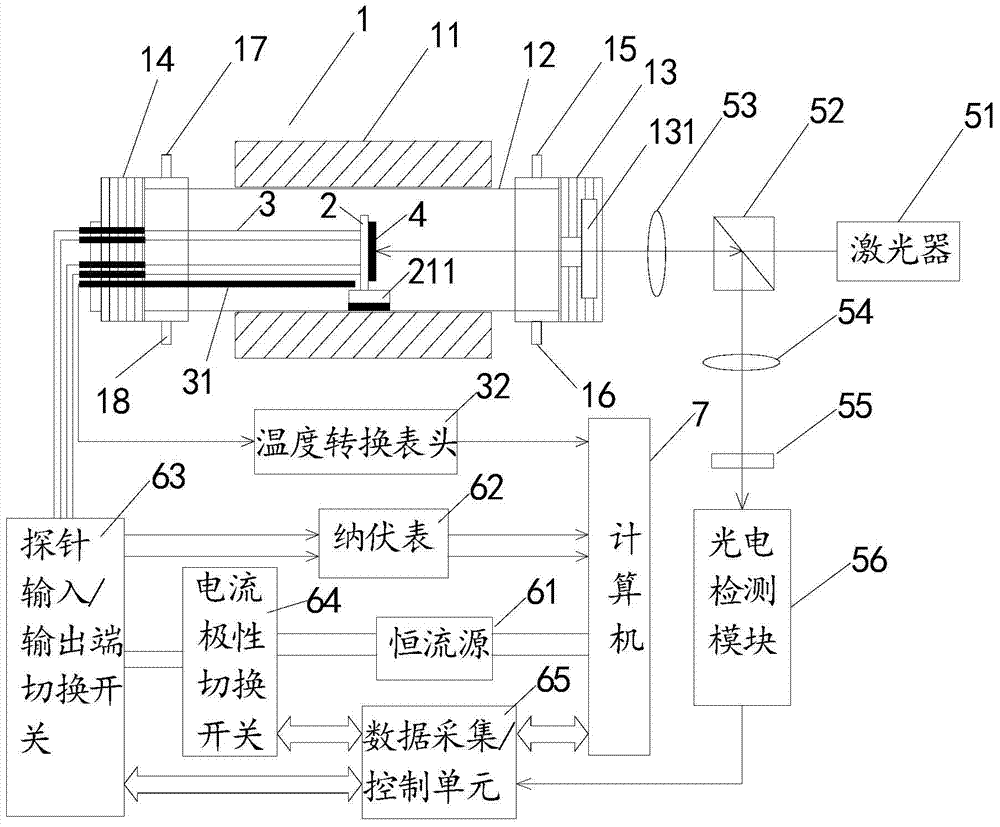

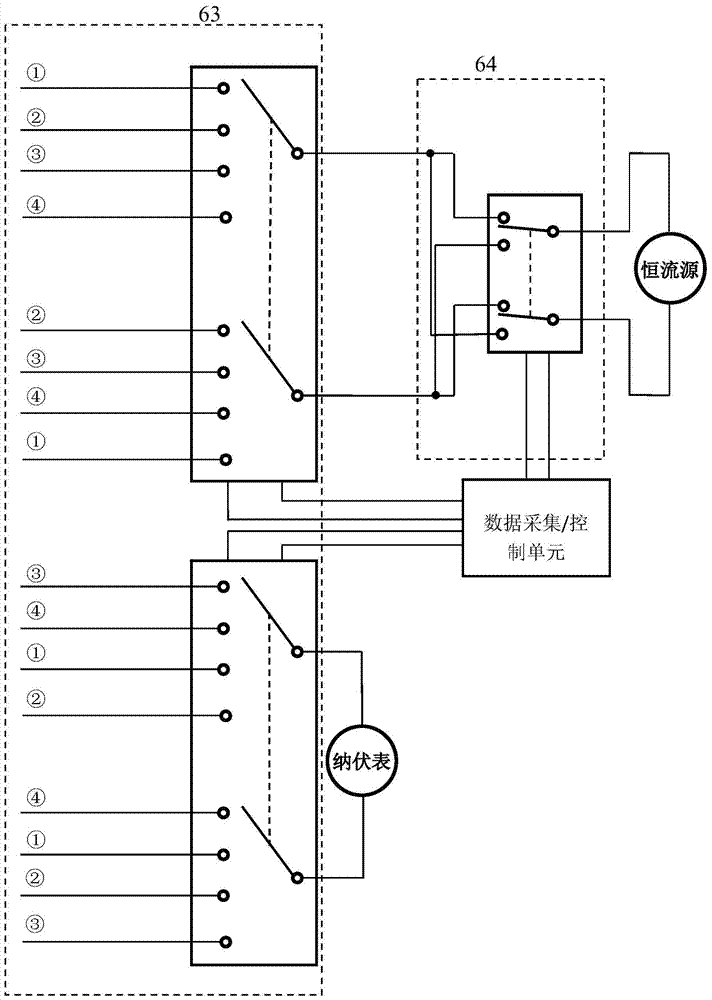

[0024] The present invention is a thin-film high-temperature optoelectronic physical property testing device, such as figure 1 As shown, it includes a temperature-controlled vacuum tube furnace, a sample test bench, a temperature measurement unit, a film surface reflected light intensity measurement unit, a film resistance detection unit and a computer.

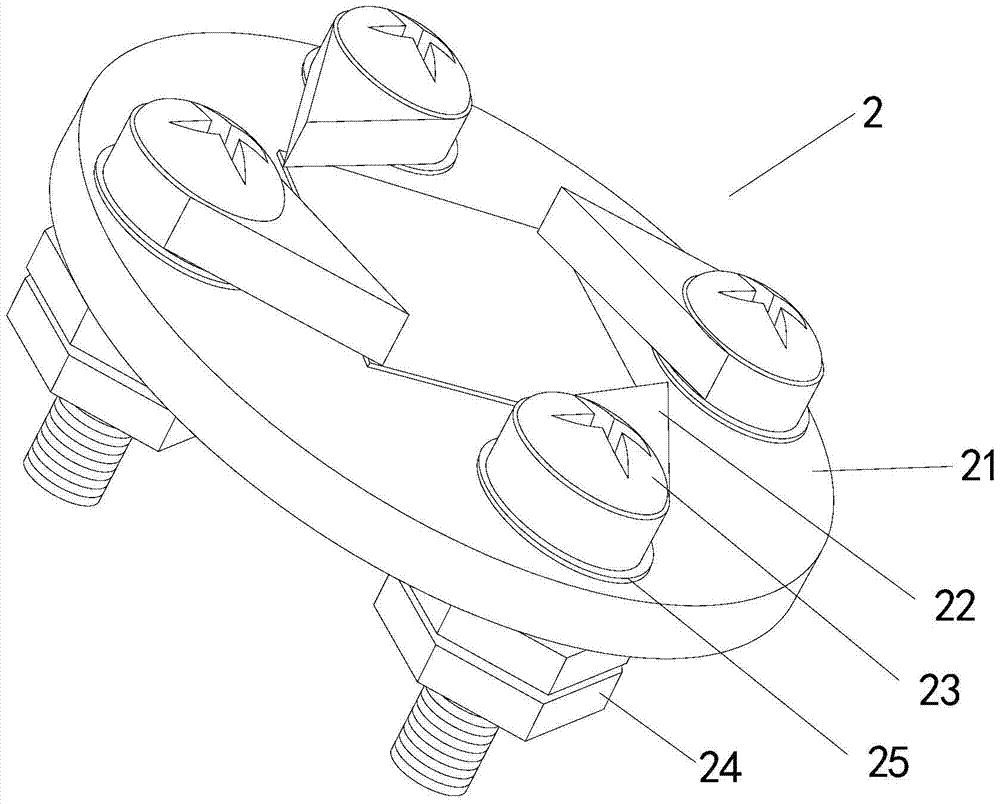

[0025] The temperature-controlled vacuum tube furnace includes a program-controlled heating tube furnace 1 and a vacuum pump (not shown) for evacuating the program-controlled heating tube furnace. This program-controlled heating tube furnace 1 includes a program-controlled heating furnace body 11 and a set Both ends of the program-controlled heating furnace body 11 are open-shaped transparent quartz tubes 12, through which the incident laser light on the sample can be observed conveniently. The first opening of the quartz tube 12 is equipped with a first sealing flange 13 having a transparent optical window 131 , and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com