Optical waveguide element and optical modulator

A technology of optical waveguide and components, applied in the field of optical modulators, can solve the problems of low light loss, difficulty in making light loss, inability to build optical communication systems, etc., and achieve the effect of low light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] Hereinafter, the present invention will be specifically described based on examples.

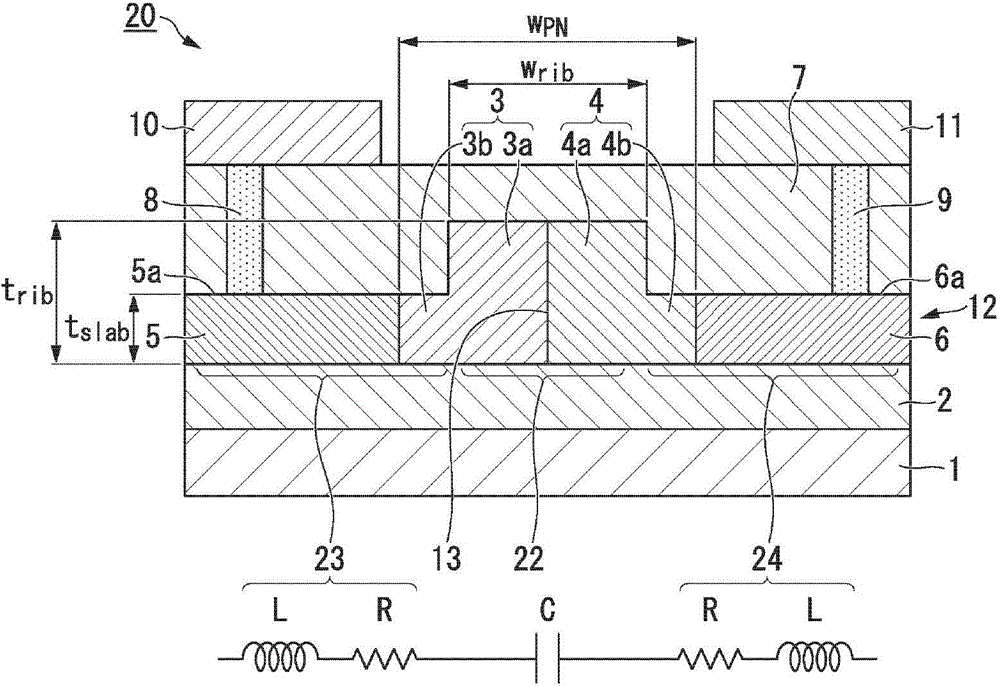

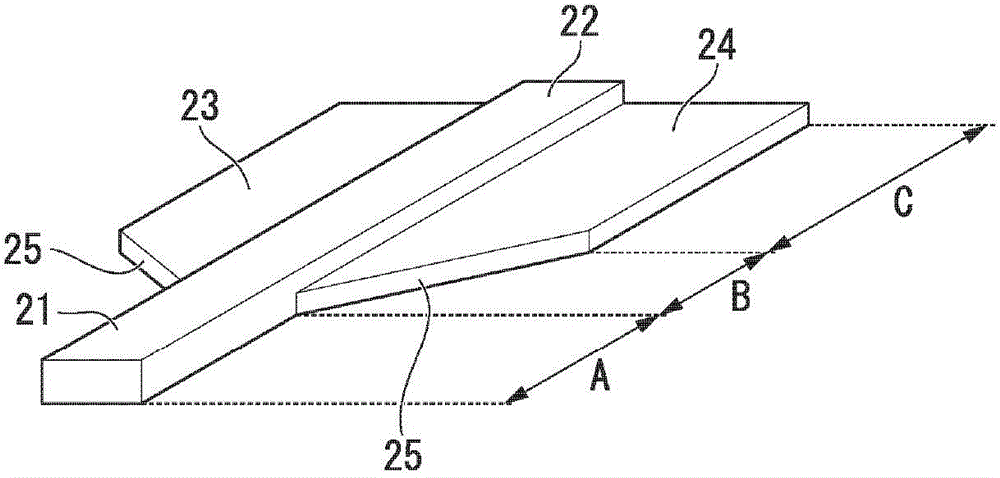

[0113] exist figure 1 In the shown structure, an SOI wafer is used as materials for the substrate 1 , the lower cover portion 2 , and the core layer 12 . The BOX layer made of silicon dioxide with a thickness of 2 μm was used as the lower cover part 2, and P-type and N-type dopants were added to the SOI layer made of silicon above it by ion implantation, thereby forming the P-type semiconductor part 3 , N-type semiconductor portion 4 , P-type conductor portion 5 , and N-type conductor portion 6 . In addition, a part of the core layer 12 was removed by etching to form the ridge portion 22 and the flat plate portions 23 and 24 . Ridge width w rib 500~600nm, ridge thickness t rib is 220nm, plate thickness t slab 95nm, the distance w between the P-type conductor part 5 and the N-type conductor part 6 PN is about 2 μm. The upper cover portion 7 made of silicon dioxide is deposited t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com