Niclosamide ethanolamine slow-release water dispersion granules and preparation process thereof

The technology of spirulina ethanolamine salt and dispersing particles is applied in the directions of biocides, molluscicides, biocides, etc., and can solve the problems such as the inability of effective ingredients to diffuse evenly with water, the inability to obtain comprehensive prevention and control, and the loss of effective ingredients of medicines. To achieve the effect of ensuring the efficacy of the drug, improving the effect of snail control, and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

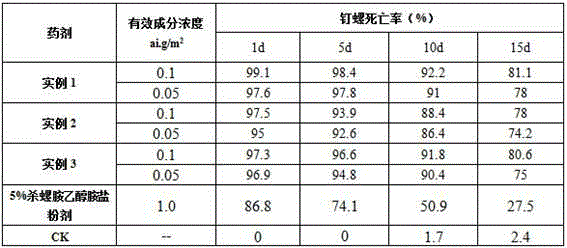

Examples

Embodiment 1

[0023] Preparation of 30% spiroxamine ethanolamine salt slow-release water-dispersible granules

[0024] a. Take by weight 30% of the raw material spiroxamine ethanolamine salt, 10% of the dispersant NNO, 5% of sodium tripolyphosphate and filler kaolin, and put it into a jet mill for pulverization;

[0025] b. The pulverized material is kneaded with 13% water, and then granulated by rotary extrusion;

[0026] c. Weigh 0.2% polyvinyl alcohol and prepare it into a polyvinyl alcohol aqueous solution with a mass concentration of 5%, put the granulated granules into a boiling dryer for drying, and spray polyethylene during the drying process Alcohol aqueous solution; then dry the granules to get the finished product. During this period, the drying temperature is controlled between 50 and 65°C, and the drying time is between 20 and 35 minutes.

Embodiment 2

[0028] Preparation of 40% spiroxamine ethanolamine salt slow-release water-dispersible granules

[0029] a. Take by weight 40% of the raw material spiroxamine ethanolamine salt, 3% of dispersant D425, 5% of dispersant NNO, 5% of sodium tripolyphosphate and filler kaolin, and put it into a jet mill for pulverization;

[0030] b. The pulverized material is kneaded with 13% water, and then granulated by rotary extrusion;

[0031] c. Weigh 0.25% polyvinyl alcohol and prepare it into a polyvinyl alcohol aqueous solution with a mass concentration of 5%, put the granulated granules into a boiling dryer for drying, and spray polyethylene during the drying process Alcohol aqueous solution; then dry the granules to get the finished product. During this period, the drying temperature is controlled between 50 and 65°C, and the drying time is between 20 and 35 minutes.

Embodiment 3

[0033] Preparation of 50% spiroxamine ethanolamine salt slow-release water-dispersible granules

[0034] a. Put 50% of spiroxamine ethanolamine salt, 5% of dispersant NNO, 1% of dispersant K30, 5% of sodium tripolyphosphate and filler kaolin into the jet mill for pulverization;

[0035] b. The pulverized material is kneaded with 13% water, and then granulated by rotary extrusion;

[0036] c. Weigh 0.25% polyvinyl alcohol and prepare it into a polyvinyl alcohol aqueous solution with a mass concentration of 5%, put the granulated granules into a boiling dryer for drying, and spray polyethylene during the drying process Alcohol aqueous solution; then dry the granules to get the finished product. During this period, the drying temperature is controlled between 50 and 65°C, and the drying time is between 20 and 35 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com