Bone screw

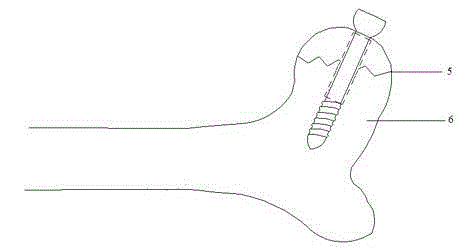

A bone screw and screw technology, applied in the direction of internal bone synthesis, medical science, surgery, etc., can solve the problems of inability to stabilize surrounding bones, lack of bone micro-motion, and unfavorable fracture prognosis, and achieve good healing effect, improved surgical success rate, Stabilizing the effect of fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

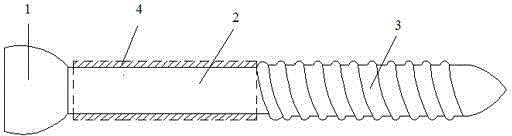

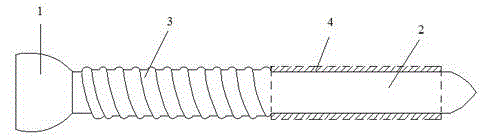

[0031] The bone screw is used as a cancellous bone screw, its diameter is 4.5mm, the major diameter of the screw section 3 (that is, the outer diameter of the thread) is 4.5mm, the diameter of the polished section 2 is 3.2mm, and the length of the polished section 2 is 20mm; Polydioxanone is molded onto the polished rod section 2 of the bone screw by thermal injection to form a degradable material layer 4 . The degradable material layer 4 is closely attached to the peripheral surface of the polished rod section 2, and has a length of 20 mm and a thickness of 0.6 mm. The degradable material layer 4 can also be compounded to the circumferential surface of the polished rod section 2 in other conventional ways.

Embodiment 2

[0033] The bone screw is used as a cancellous bone screw, its diameter is 2.5mm, the major diameter of the screw rod section 3 is 2.5mm, the diameter of the polished rod section 2 is 1.8mm, and the length of the polished rod section 2 is 20mm; Poly-L-lactic acid is molded onto the polished shaft section 2 of the bone screw to form a layer 4 of degradable material. The degradable material layer 4 is closely attached to the peripheral surface of the polished rod section 2, and has a length of 11 mm and a thickness of 0.3 mm.

Embodiment 3

[0035] This bone screw is used as a screw for pressing and locking the steel plate. Its diameter is 4.5mm, the major diameter of the screw rod section 3 is 4.5mm, the diameter of the polished rod section 2 is 3.0mm, and the length of the polished rod section 2 is 40mm. External threads are formed on the outer circle; polydioxanone is molded onto the polished rod section 2 of the bone screw by thermal injection to form a degradable material layer 4 . The degradable material layer 4 is closely attached to the peripheral surface of the polished rod section 2, and has a length of 35 mm and a thickness of 0.7 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com