Organic exhaust gas treatment device and exhaust gas treatment method using the same

A technology for organic waste gas and treatment devices, which is applied in the direction of gaseous effluent wastewater treatment, separation methods, sustainable biological treatment, etc., can solve the problems of blocked spray towers, difficult to clean, and difficult to operate stably for a long time, and achieve full gas-liquid contact , Easy to clean and maintain, complete and thorough treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

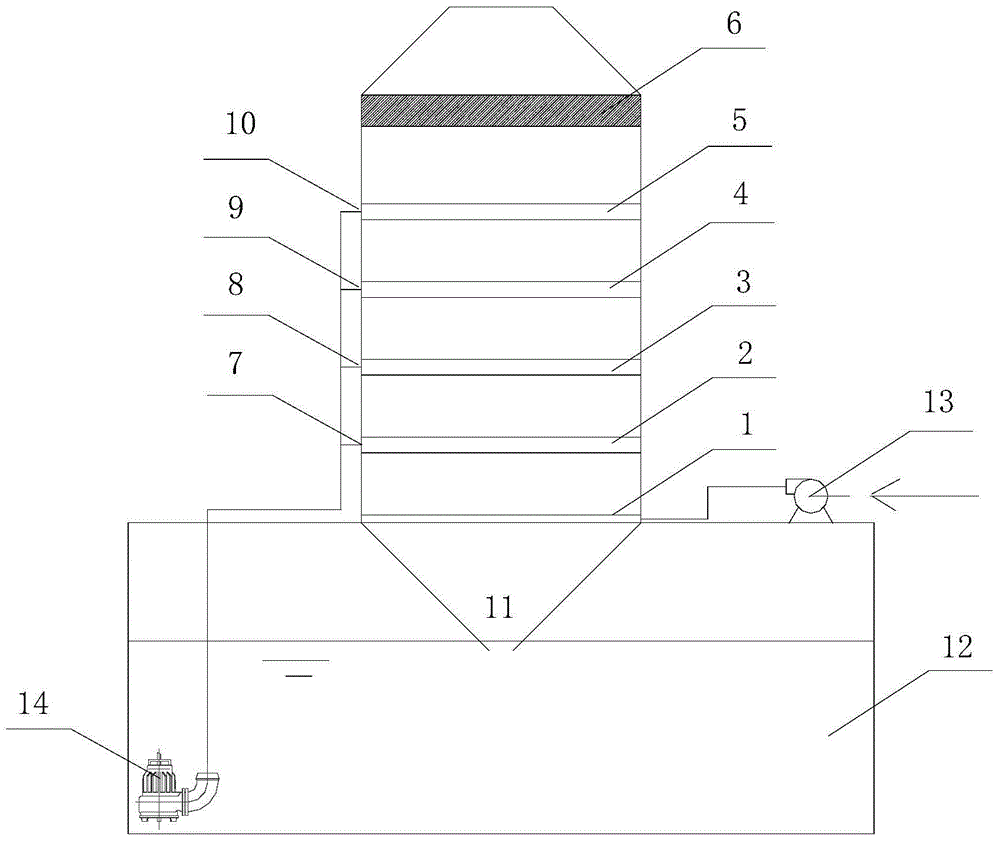

[0027] Please refer to figure 1 , an organic waste gas treatment device according to an embodiment of the present invention includes a spray tower and a membrane bioreactor pool 12 arranged under the spray tower, and a drawer-type gas distribution structure 1, a first-stage Drawer-type spray air distribution structure 2, two-level drawer-type spray air distribution structure 3, three-level drawer-type spray air distribution structure 4, four-level drawer-type spray air distribution structure 5 and drawer-type defoaming structure 6, one The first-level drawer-type spray air distribution structure 2 is equipped with the first-level activated sludge mixed liquid inlet 7, the second-level drawer-type spray air distribution structure 3 is equipped with the second-level activated sludge mixed liquid inlet 8, and the third-level drawer-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com