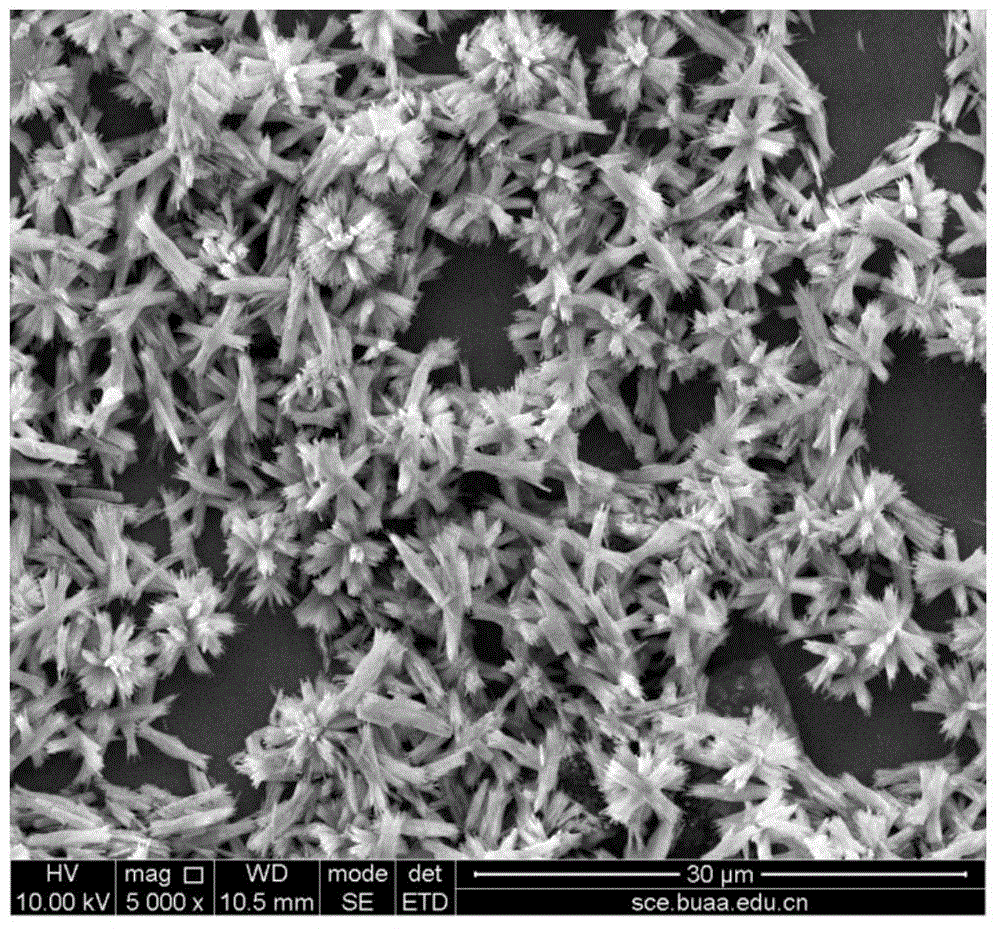

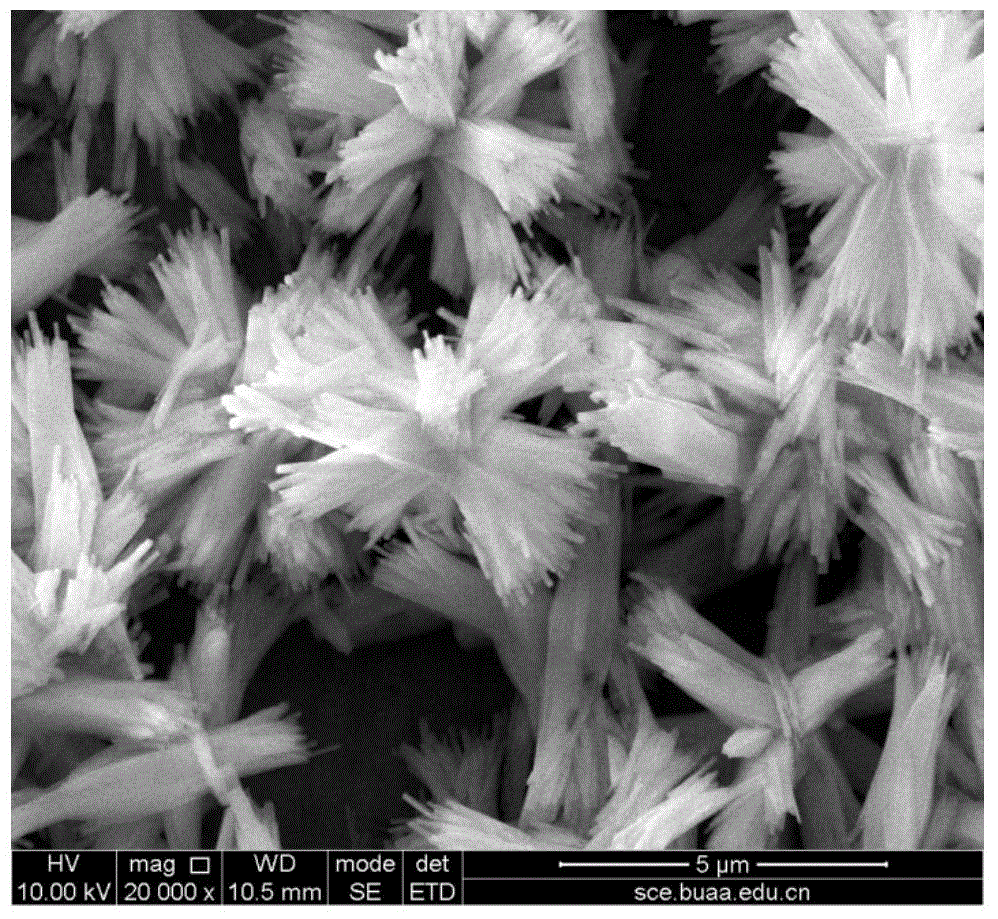

Preparation method of needle shaped edge nickel oxide nano flowers of

A nanoflower and nickel oxide technology, applied in the field of nanomaterials, can solve the problems of hindering particle diffusion, impact, particle diffusion and specific surface area disadvantages, and achieve the effects of enhancing adsorption capacity, simplifying process steps, and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step (1): Add 0.3g NiCl to 20ml deionized water 2 ·6H 2 O, to which 0.07 g of Na was added after stirring for 15 minutes 2 C 2 o 4 Solid, stirred for 30 minutes with a magnetic stirrer;

[0024] Step (2): add 20ml EG (ethylene glycol) liquid to above-mentioned solution, stir 30 minutes with magnetic stirrer;

[0025] Step (3): Put the above solution into a hydrothermal kettle, heat it at 200°C and cool it with the furnace. Then the obtained solution was centrifuged and washed 8 times, then dried at 60°C for 30 hours, then ground into powder, put into a crucible, and calcined at a temperature range of 400°C to obtain the nickel oxide needle-shaped edge nanoflowers .

Embodiment 2

[0027] Step (1): Add 0.33g NiCl to 20ml deionized water 2 ·6H 2 O, to which 0.07 g of Na was added after stirring for 20 minutes 2 C 2 o 4 Solid, stirred for 30 minutes with a magnetic stirrer;

[0028] Step (2): add 20ml EG (ethylene glycol) liquid to above-mentioned solution, stir 30 minutes with magnetic stirrer;

[0029] Step (3): Put the above solution into a hydrothermal kettle, heat it at 190°C and cool it with the furnace. The resulting solution was centrifuged and washed 8 times, then dried at 60°C for 30 hours, then ground into powder, put into a crucible, and calcined at a temperature range of 390°C to obtain the nickel oxide needle-shaped edge nanoflowers .

Embodiment 3

[0031] Step (1): Add 0.27g NiCl to 20ml deionized water 2 ·6H 2 O, to which 0.06 g of Na was added after stirring for 10 minutes 2 C 2 o 4 Solid, stirred for 35 minutes with a magnetic stirrer;

[0032] Step (2): add 20ml EG (ethylene glycol) liquid to above-mentioned solution, stir 25 minutes with magnetic stirrer;

[0033] Step (3): Put the above solution into a hydrothermal kettle, heat it at 180°C and cool it with the furnace. The resulting solution was centrifuged and washed 6 times, then dried at 80°C for 25 hours, then ground into powder, put into a crucible, and calcined at a temperature range of 420°C to obtain the nickel oxide needle-shaped edge nanoflowers .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com