Method for operating anaerobic ammoxidation reactor capable of rapidly restarting heavy metal pollution

A technology of anaerobic ammonium oxidation and operation method, which is applied in the field of fast restarting the operation of heavy metal-contaminated anaerobic ammonium oxidation reactors, can solve the problems of heavy metal impact on the reactor, affecting the operating performance of the reactor, and the collapse of the reactor, and achieves Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

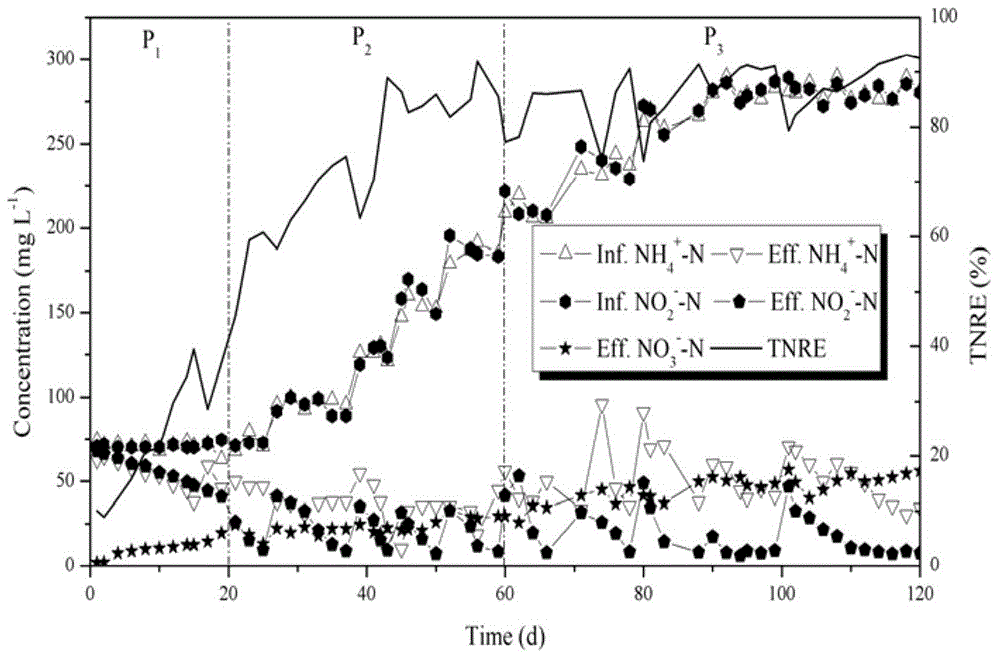

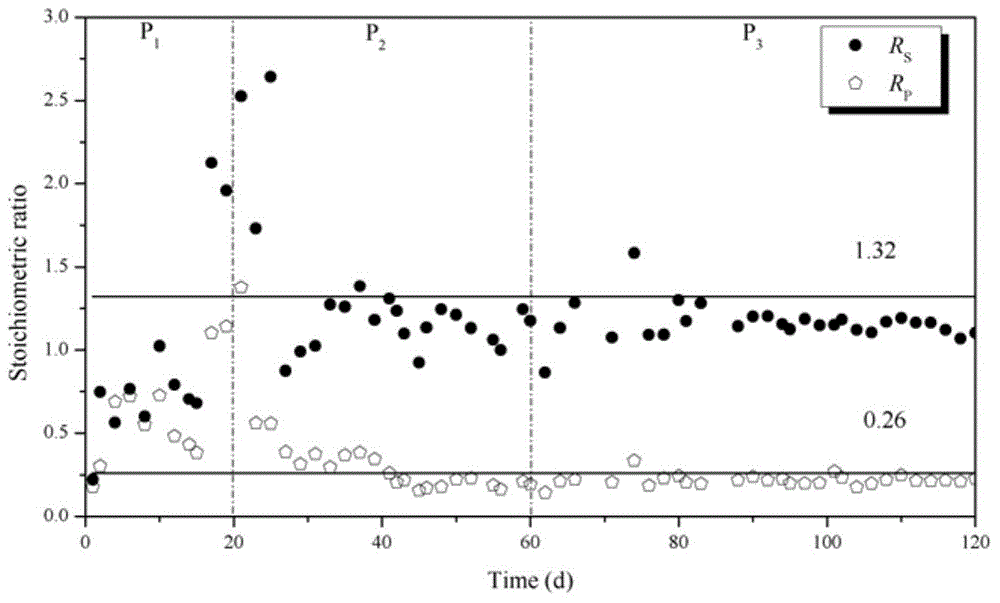

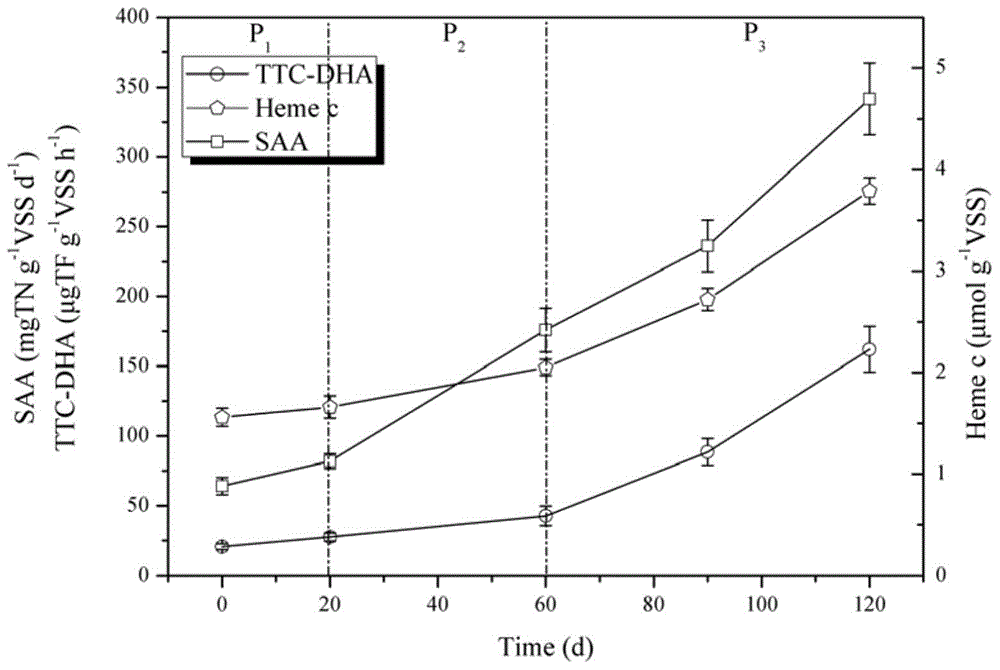

[0023] A kind of operation method of the anaerobic ammonium oxidation reactor of a kind of rapid restart heavy metal contamination of the present invention, test sludge is taken from the upflow type anaerobic sludge bed reactor (at concentration 5, 8, 10, 12 mg Cu L -1 each run for two weeks).

[0024] The restart operation is as follows:

[0025] (1) Divide 500ml of anammox sludge into ten 1000ml Erlenmeyer flasks with stoppers, add 500ml of chelating cleaning solution, and use 2mol·L -1 Dilute hydrochloric acid and 2mol·L -1 The pH was adjusted to 7.50 with NaOH solution. After flushing with argon gas for deoxygenation for 10 minutes, tightly cover the plug and place it in a water bath shaker, shake it at 35°C and 180rpm for 12 hours, let the mud-water mixture stand still, discard the upper layer of cleaning solution, remove the lower layer of sludge, and then use inorganic salt solution (volume ratio 1:10) shake and wash 3 times, each time for 30 minutes, to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com